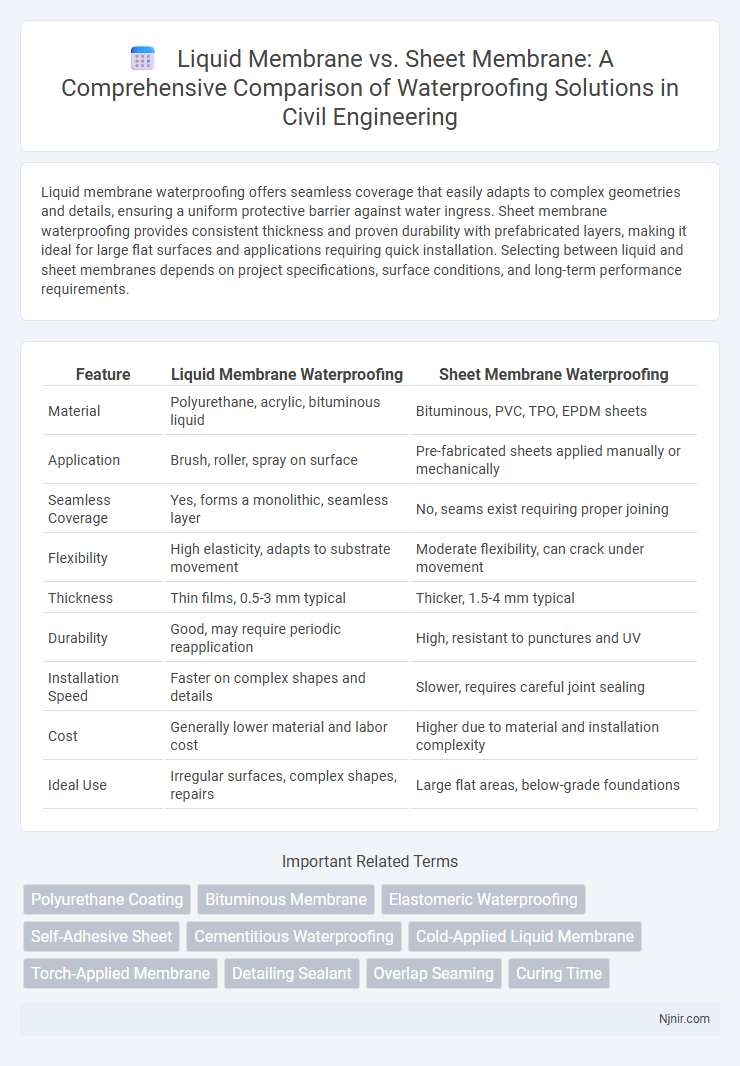

Liquid membrane waterproofing offers seamless coverage that easily adapts to complex geometries and details, ensuring a uniform protective barrier against water ingress. Sheet membrane waterproofing provides consistent thickness and proven durability with prefabricated layers, making it ideal for large flat surfaces and applications requiring quick installation. Selecting between liquid and sheet membranes depends on project specifications, surface conditions, and long-term performance requirements.

Table of Comparison

| Feature | Liquid Membrane Waterproofing | Sheet Membrane Waterproofing |

|---|---|---|

| Material | Polyurethane, acrylic, bituminous liquid | Bituminous, PVC, TPO, EPDM sheets |

| Application | Brush, roller, spray on surface | Pre-fabricated sheets applied manually or mechanically |

| Seamless Coverage | Yes, forms a monolithic, seamless layer | No, seams exist requiring proper joining |

| Flexibility | High elasticity, adapts to substrate movement | Moderate flexibility, can crack under movement |

| Thickness | Thin films, 0.5-3 mm typical | Thicker, 1.5-4 mm typical |

| Durability | Good, may require periodic reapplication | High, resistant to punctures and UV |

| Installation Speed | Faster on complex shapes and details | Slower, requires careful joint sealing |

| Cost | Generally lower material and labor cost | Higher due to material and installation complexity |

| Ideal Use | Irregular surfaces, complex shapes, repairs | Large flat areas, below-grade foundations |

Introduction to Waterproofing in Civil Engineering

Waterproofing in civil engineering is essential for protecting structures from water ingress that can cause deterioration and structural failures. Liquid membrane waterproofing offers seamless application with excellent adaptability to complex surfaces, ensuring thorough coverage and flexibility under stress. Sheet membrane waterproofing provides a durable, pre-formed barrier with consistent thickness, ideal for large flat areas and below-grade foundations requiring robust protection.

Overview of Liquid Membrane Waterproofing

Liquid membrane waterproofing involves applying a seamless, flexible coating that cures to form a durable barrier against water infiltration, making it ideal for complex surfaces and detailing. This method adapts easily to irregular shapes, cracks, and joints, ensuring comprehensive protection with minimal risk of punctures or seams. Its quick curing time and compatibility with various substrates enhance structural longevity and resistance to moisture-related damage.

Overview of Sheet Membrane Waterproofing

Sheet membrane waterproofing involves applying pre-formed rolls of synthetic materials like modified bitumen or PVC to surfaces, creating a durable barrier against water infiltration. These membranes offer consistent thickness, UV resistance, and ease of installation on large, flat areas such as roofs, foundations, and basements. Their performance is enhanced by cold adhesive or heat welding techniques, ensuring seamless protection in challenging environmental conditions.

Application Techniques: Liquid vs Sheet Membranes

Liquid membrane waterproofing offers seamless application by being sprayed, rolled, or brushed directly onto surfaces, allowing it to conform to complex shapes and intricate details. Sheet membranes require precise cutting and careful adhesion to surfaces, often involving heat or primer to ensure proper bonding and prevent leaks at seams. Liquid membranes provide faster coverage on uneven or irregular substrates, while sheet membranes deliver consistent thickness and durability on flat, well-prepared surfaces.

Material Performance and Properties Comparison

Liquid membranes offer superior flexibility and seamless application, enabling excellent adhesion to complex surfaces and reducing the risk of leaks. Sheet membranes provide consistent thickness and durability, with high tensile strength and puncture resistance, but may experience joint-related vulnerabilities. Both materials are waterproof and UV resistant, though liquid membranes excel in adaptability, while sheet membranes perform better in high-traffic areas.

Durability and Lifespan of Waterproofing Systems

Liquid membrane waterproofing offers superior durability by forming a seamless, flexible barrier that adapts to structural movements and resists cracking over time. Sheet membrane waterproofing provides a consistent thickness and high resistance to punctures but may be prone to seam failures, reducing its overall lifespan in dynamic or uneven surfaces. The effective lifespan of liquid membranes typically ranges from 10 to 20 years, while sheet membranes can last 15 to 30 years depending on installation quality and environmental exposure.

Installation Challenges and Solutions

Liquid membrane waterproofing requires careful surface preparation and precise application techniques to ensure uniform coverage and avoid pinholes, with solutions including the use of spray or roller equipment and trained applicators to achieve consistent thickness. Sheet membrane waterproofing poses challenges such as ensuring proper adhesion to complex surfaces, managing seams, and avoiding wrinkles; these issues are mitigated by using self-adhesive sheets, heat welding seams, and employing skilled installers for meticulous placement. Both methods demand environmental controls like temperature and humidity monitoring to optimize curing and adhesion, enhancing overall waterproofing performance.

Cost Analysis: Liquid vs Sheet Membranes

Liquid membranes generally offer lower initial installation costs than sheet membranes due to easier application processes and reduced labor requirements. Sheet membranes, while more expensive upfront, provide consistent thickness and durability, potentially lowering long-term maintenance expenses. Evaluating total lifecycle costs, including material, labor, and repair expenses, is crucial for accurate waterproofing budget decisions.

Typical Use Cases and Project Suitability

Liquid membrane waterproofing offers superior adaptability for complex or irregularly shaped surfaces like balconies, basements, and roofing systems, providing seamless coverage that prevents water ingress. Sheet membranes are ideal for large, flat areas such as foundations, tunnels, and parking decks where uniform thickness and fast installation are critical for project timelines. Both methods suit different project scales and conditions; liquid membranes excel in intricate applications requiring flexibility, while sheet membranes are preferred for standardized, high-volume deployments.

Conclusion: Selecting the Right Waterproofing Method

Liquid membrane waterproofing offers seamless coverage and adaptability to complex surfaces, ensuring superior flexibility and durability in dynamic environments. Sheet membrane waterproofing provides consistent thickness and easy quality control, making it ideal for flat or regular surfaces with long-term reliability. Selecting the right waterproofing method depends on structural requirements, surface complexity, and environmental conditions to maximize waterproof performance and lifespan.

Polyurethane Coating

Polyurethane coating in liquid membrane waterproofing offers superior flexibility, seamless application, and enhanced durability compared to sheet membrane waterproofing.

Bituminous Membrane

Bituminous sheet membranes provide durable waterproofing with high resistance to UV and chemicals, while liquid membranes offer seamless application and superior adhesion, but bituminous membranes excel in long-term protection for roofing and below-grade structures.

Elastomeric Waterproofing

Elastomeric waterproofing offers superior flexibility and durability compared to sheet membranes, forming a seamless, liquid-applied barrier that effectively adapts to structural movements and prevents water infiltration.

Self-Adhesive Sheet

Self-adhesive sheet membranes offer superior waterproofing durability and ease of installation compared to liquid membranes by providing consistent thickness and immediate adhesion without the need for drying time.

Cementitious Waterproofing

Cementitious waterproofing, a type of liquid membrane, offers seamless application and superior adhesion to concrete surfaces compared to sheet membranes, enhancing durability and crack resistance in waterproofing systems.

Cold-Applied Liquid Membrane

Cold-applied liquid membrane waterproofing offers superior flexibility, seamless application, and excellent adhesion on complex surfaces compared to traditional sheet membrane waterproofing.

Torch-Applied Membrane

Torch-applied sheet membranes provide superior durability and seamless waterproofing compared to liquid membranes by creating a heat-activated, reinforced barrier ideal for roofing and below-grade applications.

Detailing Sealant

Liquid membrane waterproofing provides superior detailing sealant flexibility and seamless adhesion compared to rigid sheet membrane options, ensuring enhanced protection against water infiltration at joints and irregular surfaces.

Overlap Seaming

Liquid membrane waterproofing creates a seamless barrier without overlap seaming, while sheet membrane waterproofing requires careful overlap seaming to prevent water infiltration at joint seams.

Curing Time

Liquid membrane waterproofing typically requires 24 to 48 hours to cure, whereas sheet membrane waterproofing offers immediate waterproofing upon installation with no curing time needed.

Liquid Membrane vs Sheet Membrane Waterproofing Infographic

njnir.com

njnir.com