Precast concrete offers superior quality control and faster installation compared to cast-in-place methods, reducing on-site labor and curing time. Cast-in-place concrete provides greater flexibility in design adjustments and better integration with existing structures due to its adaptability during construction. Selecting between precast and cast-in-place depends on project timelines, budget constraints, and the complexity of the structural design.

Table of Comparison

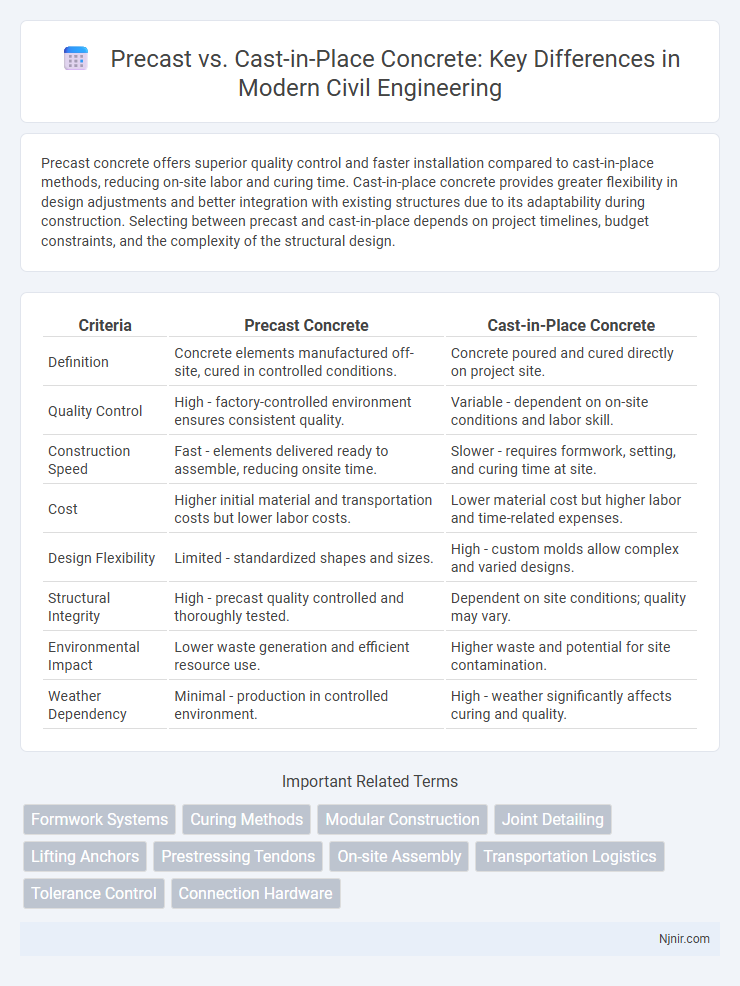

| Criteria | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Definition | Concrete elements manufactured off-site, cured in controlled conditions. | Concrete poured and cured directly on project site. |

| Quality Control | High - factory-controlled environment ensures consistent quality. | Variable - dependent on on-site conditions and labor skill. |

| Construction Speed | Fast - elements delivered ready to assemble, reducing onsite time. | Slower - requires formwork, setting, and curing time at site. |

| Cost | Higher initial material and transportation costs but lower labor costs. | Lower material cost but higher labor and time-related expenses. |

| Design Flexibility | Limited - standardized shapes and sizes. | High - custom molds allow complex and varied designs. |

| Structural Integrity | High - precast quality controlled and thoroughly tested. | Dependent on site conditions; quality may vary. |

| Environmental Impact | Lower waste generation and efficient resource use. | Higher waste and potential for site contamination. |

| Weather Dependency | Minimal - production in controlled environment. | High - weather significantly affects curing and quality. |

Introduction to Precast and Cast-in-Place Concrete

Precast concrete involves casting concrete elements in a controlled factory environment before transporting them to the construction site, ensuring high quality and uniformity. Cast-in-place concrete is poured and cured directly at the construction site, allowing for greater flexibility in design and complex geometries. Both methods offer unique advantages in structural strength, construction speed, and cost efficiency depending on project requirements.

Definition and Overview of Precast Concrete

Precast concrete refers to structural components that are manufactured and cured in a controlled factory environment before being transported to the construction site for installation. This method ensures high quality control, faster construction times, and reduces onsite labor compared to cast-in-place concrete, which is poured and cured directly at the construction site. Precast elements include beams, slabs, columns, and panels, offering versatility and durability for various building and infrastructure projects.

Definition and Overview of Cast-in-Place Concrete

Cast-in-place concrete refers to concrete that is poured and cured directly at the construction site within formwork designed for the specific structure. This method allows for seamless integration with other structural elements, offering flexibility in shape and design modifications during construction. It is commonly used for foundations, columns, and slabs where on-site customization and monolithic strength are essential.

Key Differences Between Precast and Cast-in-Place

Precast concrete is manufactured in a controlled factory environment, allowing for higher quality control and faster construction times compared to cast-in-place concrete, which is poured and cured directly on the construction site. Precast components offer uniformity and reduced labor costs, whereas cast-in-place provides greater flexibility in design and on-site adjustments. The choice between precast and cast-in-place concrete depends on factors such as project timeline, budget, structural complexity, and site conditions.

Installation and Construction Process Comparison

Precast concrete components are manufactured off-site under controlled conditions, allowing for rapid on-site installation with minimal labor and reduced weather dependency. Cast-in-place concrete requires on-site formwork setup, reinforcement placement, and curing time, leading to longer construction schedules and higher susceptibility to weather delays. The streamlined installation process of precast elements results in improved quality control, faster project completion, and lower overall labor costs compared to traditional cast-in-place methods.

Structural Performance and Durability

Precast concrete offers superior structural performance through controlled factory conditions, ensuring consistent strength, reduced permeability, and improved durability compared to cast-in-place methods. Cast-in-place concrete provides monolithic continuity and flexible design adaptability but may experience variability in curing conditions, leading to potential weaknesses and increased susceptibility to cracking. The enhanced quality control in precast components results in better resistance to environmental stressors, reducing maintenance costs and extending service life.

Cost Analysis: Precast vs Cast-in-Place

Precast concrete offers cost savings through reduced labor expenses and shorter construction schedules compared to cast-in-place methods, which often require extensive formwork and on-site labor. While precast components may have higher initial manufacturing costs, the ability to mass-produce elements in a controlled environment minimizes waste and rework. Cast-in-place concrete tends to incur higher costs related to weather delays, material spoilage, and longer curing times that can extend project timelines and increase overall expenses.

Flexibility and Design Considerations

Precast concrete offers limited on-site flexibility due to factory-controlled fabrication and predefined dimensions, making it ideal for repetitive, modular designs. Cast-in-place concrete provides greater design adaptability, allowing for complex shapes, custom dimensions, and adjustments during construction. Structural engineers often choose cast-in-place methods when architectural flexibility and site-specific modifications are critical.

Sustainability and Environmental Impact

Precast concrete reduces environmental impact by minimizing onsite waste and allowing for factory-controlled quality, resulting in less material waste and energy consumption compared to cast-in-place methods. Factory production enables the use of recycled materials and lower carbon footprints through optimized curing processes, whereas cast-in-place concrete typically involves higher water usage and onsite emissions from formwork and mixing. Lifecycle assessments reveal that precast components contribute to better sustainability performance due to enhanced durability, reduced construction time, and efficient resource utilization.

Applications and Best Use Cases

Precast concrete is ideal for large-scale projects requiring repetitive units, such as parking garages, bridges, and modular buildings, due to its quality control and rapid installation. Cast-in-place concrete is best suited for complex structures with custom shapes, foundations, and infrastructure requiring on-site flexibility and integration. Selecting between precast and cast-in-place depends on project scale, design complexity, and construction timeline.

Formwork Systems

Precast formwork systems offer faster installation, higher quality control, and reusable molds compared to the customizable but labor-intensive and time-consuming cast-in-place formwork systems.

Curing Methods

Precast concrete uses factory-controlled curing methods like steam curing for faster strength gain, while cast-in-place concrete relies primarily on on-site water curing to ensure proper hydration and durability.

Modular Construction

Precast concrete panels in modular construction offer faster installation and improved quality control compared to cast-in-place methods, reducing on-site labor and construction time significantly.

Joint Detailing

Precast concrete offers precise, factory-controlled joint detailing with uniform quality, while cast-in-place joint detailing allows for flexible, site-specific customization but often requires meticulous on-site labor and quality control.

Lifting Anchors

Precast lifting anchors offer superior load capacity and faster installation compared to cast-in-place anchors, reducing construction time and enhancing safety.

Prestressing Tendons

Prestressing tendons in precast concrete are tensioned before concrete placement for enhanced control and quality, whereas in cast-in-place concrete, tendons are tensioned after casting to accommodate on-site adjustments.

On-site Assembly

Precast concrete enables faster on-site assembly with factory-controlled quality and minimal curing time, while cast-in-place concrete requires longer on-site formwork setup and curing processes.

Transportation Logistics

Precast concrete elements streamline transportation logistics by allowing off-site manufacturing and controlled packaging, reducing transit risks compared to the heavy, bulky, and weather-sensitive cast-in-place concrete that requires on-site pouring and curing.

Tolerance Control

Precast concrete offers superior tolerance control compared to cast-in-place methods due to factory-controlled environments and precise formwork, ensuring consistent dimensions and minimizing on-site variability.

Connection Hardware

Precast concrete relies on specialized embedded connection hardware for rapid assembly and structural integrity, while cast-in-place concrete uses conventional rebar and form-tied connections integrated during on-site pouring.

Precast vs Cast-in-Place Infographic

njnir.com

njnir.com