Mass timber offers sustainable advantages over structural steel by utilizing renewable wood resources, reducing carbon emissions, and providing superior thermal insulation. Structural steel, favored for its high strength-to-weight ratio and flexibility in design, enables faster construction and greater resistance to seismic activity. Combining both materials in hybrid structures can optimize performance, durability, and environmental impact in modern civil engineering projects.

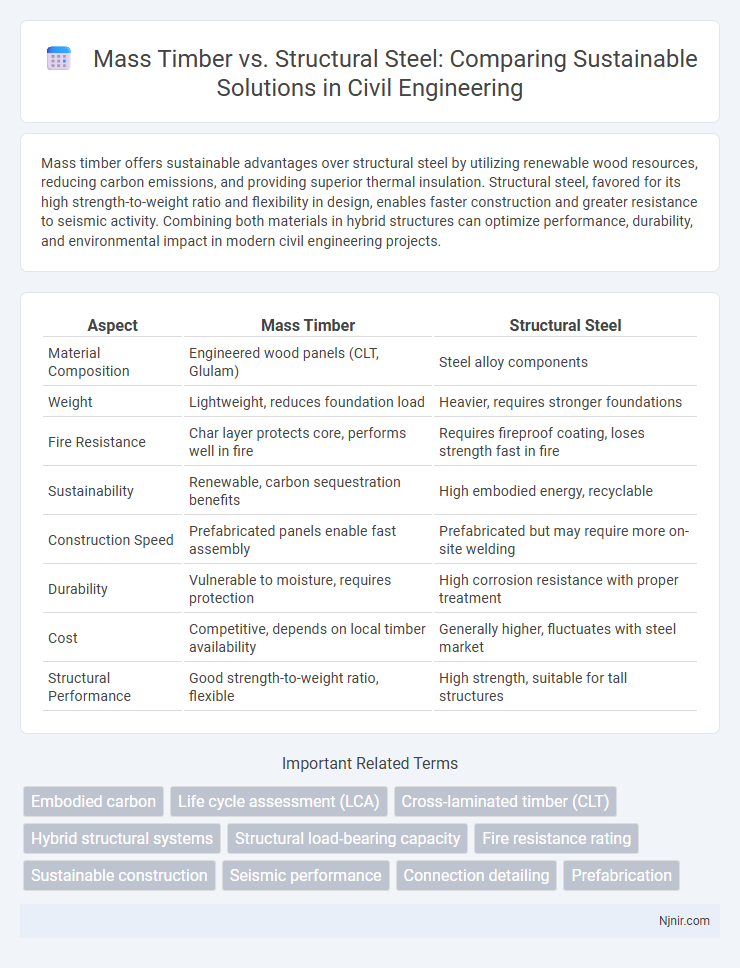

Table of Comparison

| Aspect | Mass Timber | Structural Steel |

|---|---|---|

| Material Composition | Engineered wood panels (CLT, Glulam) | Steel alloy components |

| Weight | Lightweight, reduces foundation load | Heavier, requires stronger foundations |

| Fire Resistance | Char layer protects core, performs well in fire | Requires fireproof coating, loses strength fast in fire |

| Sustainability | Renewable, carbon sequestration benefits | High embodied energy, recyclable |

| Construction Speed | Prefabricated panels enable fast assembly | Prefabricated but may require more on-site welding |

| Durability | Vulnerable to moisture, requires protection | High corrosion resistance with proper treatment |

| Cost | Competitive, depends on local timber availability | Generally higher, fluctuates with steel market |

| Structural Performance | Good strength-to-weight ratio, flexible | High strength, suitable for tall structures |

Introduction to Mass Timber and Structural Steel

Mass timber, engineered from layers of wood bonded together, offers a renewable, lightweight alternative to traditional construction materials, emphasizing sustainability and carbon sequestration. Structural steel, composed of fabricated steel components, provides high strength, durability, and design flexibility, making it ideal for large-scale, high-rise buildings. Both materials play critical roles in modern architecture, with mass timber gaining popularity for mid-rise projects and structural steel dominating in skyscraper construction.

Material Properties and Performance Comparison

Mass timber offers superior thermal insulation and a lower carbon footprint compared to structural steel, which excels in tensile strength and fire resistance. Structural steel provides greater design flexibility and faster construction times due to its uniformity and prefabrication capabilities. Mass timber's lightweight nature reduces foundation loads, while steel's high strength-to-weight ratio supports taller and more complex structures.

Sustainability and Environmental Impact

Mass timber offers a renewable alternative to structural steel by capturing and storing carbon dioxide throughout its lifecycle, significantly reducing the overall carbon footprint of construction projects. Structural steel production generates high levels of greenhouse gas emissions due to energy-intensive manufacturing processes reliant on nonrenewable resources. Utilizing mass timber promotes sustainable forest management and decreases construction waste, enhancing environmental benefits compared to the traditional steel industry.

Cost Analysis and Economic Considerations

Mass timber offers cost advantages through faster construction times and reduced labor expenses compared to structural steel, which typically involves higher material and fabrication costs. Life-cycle cost analysis often favors mass timber due to its sustainability credentials and potential for energy savings in building operations. However, structural steel may provide long-term economic benefits in high-rise or complex buildings where its strength-to-weight ratio enables more efficient designs.

Design Flexibility and Architectural Opportunities

Mass timber offers superior design flexibility through its lightweight nature and ease of modification on-site, enabling complex shapes and large spans that encourage innovative architectural forms. Structural steel provides exceptional strength-to-weight ratio and modularity, supporting expansive open spaces and adaptable building layouts with rapid assembly. Both materials present unique architectural opportunities, with mass timber emphasizing sustainability and warmth, while steel allows for sleek, modern aesthetics and high-rise construction.

Construction Speed and Efficiency

Mass timber construction significantly reduces build time through prefabricated panels that enable rapid on-site assembly, streamlining labor requirements and minimizing weather-related delays. Structural steel offers high precision fabrication and quick erection, but often necessitates additional time for welding, bolting, and fireproofing treatments, slightly extending the overall schedule. Projects utilizing mass timber typically experience enhanced construction efficiency and faster completion compared to conventional steel frameworks due to simplified logistics and lighter material handling.

Fire Resistance and Safety Features

Mass timber offers improved fire resistance through charring, which protects the inner layers and maintains structural integrity longer than unprotected steel. Structural steel requires fireproofing treatments such as intumescent coatings or sprinkler systems to prevent rapid loss of strength at high temperatures. Fire safety codes increasingly recognize mass timber's performance, emphasizing engineered wood products like cross-laminated timber (CLT) for sustainable and safe construction.

Durability and Maintenance Requirements

Mass timber offers natural durability through engineered wood products like cross-laminated timber (CLT), which resist moisture and pests when properly treated but may require periodic sealing and inspection to prevent decay. Structural steel provides superior durability with inherent resistance to rot, pests, and fire, though it demands regular maintenance such as corrosion protection and repainting, especially in harsh environments. Both materials necessitate tailored maintenance strategies, with mass timber emphasizing moisture control and steel focusing on rust prevention to ensure long-term structural integrity.

Regulatory Standards and Building Codes

Mass timber and structural steel are governed by distinct regulatory standards and building codes that reflect their material properties and fire performance characteristics. Mass timber construction must comply with provisions outlined in standards like the International Building Code (IBC) Chapter 23 and ANSI/APA PRG 320, which address fire resistance, structural integrity, and allowable height and area limitations tailored to engineered wood products. Structural steel follows codes such as ASTM A6 for specifications and the AISC Steel Construction Manual, with rigorous fireproofing requirements under NFPA 251 or ASTM E119 to meet safety standards in commercial and high-rise applications.

Future Trends in Structural Materials

Mass timber is increasingly favored in sustainable construction for its carbon sequestration properties and renewable sourcing, contrasting with structural steel's high embodied energy and dependency on fossil fuels. Innovations in engineered wood, such as cross-laminated timber (CLT) and glue-laminated timber (glulam), are expanding height and load-bearing capacities, challenging traditional steel's dominance in high-rise and commercial buildings. Future trends emphasize hybrid structures combining mass timber and steel to optimize strength, sustainability, and cost-efficiency within evolving green building standards.

Embodied carbon

Mass timber demonstrates significantly lower embodied carbon compared to structural steel, making it a more sustainable choice for reducing the environmental impact of building construction.

Life cycle assessment (LCA)

Mass timber demonstrates a lower carbon footprint and reduced environmental impact over its life cycle assessment (LCA) compared to structural steel, due to renewable material sourcing and carbon sequestration during tree growth.

Cross-laminated timber (CLT)

Cross-laminated timber (CLT) offers a sustainable, lightweight, and thermally efficient alternative to structural steel, enabling faster construction times and lower carbon footprints in mass timber buildings.

Hybrid structural systems

Hybrid structural systems combining mass timber and structural steel optimize strength, sustainability, and design flexibility for modern construction projects.

Structural load-bearing capacity

Mass timber offers competitive structural load-bearing capacity with enhanced sustainability, while structural steel provides superior strength-to-weight ratio and greater load-bearing efficiency for high-rise and heavy-load applications.

Fire resistance rating

Mass timber typically achieves a fire resistance rating of 1 to 2 hours due to its charring properties, while structural steel requires fireproofing measures to maintain similar fire resistance ratings ranging from 1 to 3 hours.

Sustainable construction

Mass timber offers a sustainable construction advantage over structural steel by significantly reducing carbon emissions through carbon sequestration and using renewable wood resources.

Seismic performance

Mass timber offers superior energy dissipation and flexibility during seismic events compared to structural steel, enhancing building resilience and reducing earthquake damage.

Connection detailing

Connection detailing in mass timber requires specialized joinery techniques and moisture considerations, whereas structural steel connections rely on standardized bolting and welding methods ensuring high strength and flexibility.

Prefabrication

Mass timber offers faster and more sustainable prefabrication compared to structural steel due to its lightweight panels and modular design flexibility.

Mass timber vs structural steel Infographic

njnir.com

njnir.com