Precast concrete components are manufactured in controlled factory environments, ensuring high quality and faster installation on-site, which reduces construction time and labor costs. Cast-in-situ concrete allows greater flexibility in design and adaptability to complex or irregular site conditions, offering continuous monolithic structures with better integration. Selecting between precast and cast-in-situ depends on project scale, site accessibility, structural requirements, and budget constraints.

Table of Comparison

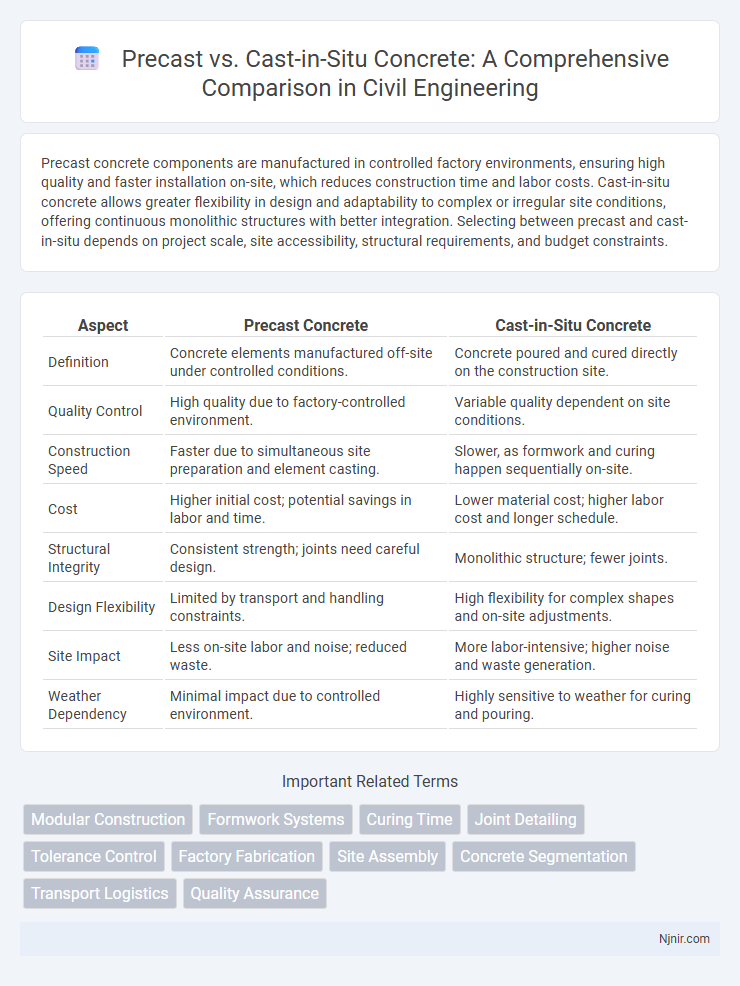

| Aspect | Precast Concrete | Cast-in-Situ Concrete |

|---|---|---|

| Definition | Concrete elements manufactured off-site under controlled conditions. | Concrete poured and cured directly on the construction site. |

| Quality Control | High quality due to factory-controlled environment. | Variable quality dependent on site conditions. |

| Construction Speed | Faster due to simultaneous site preparation and element casting. | Slower, as formwork and curing happen sequentially on-site. |

| Cost | Higher initial cost; potential savings in labor and time. | Lower material cost; higher labor cost and longer schedule. |

| Structural Integrity | Consistent strength; joints need careful design. | Monolithic structure; fewer joints. |

| Design Flexibility | Limited by transport and handling constraints. | High flexibility for complex shapes and on-site adjustments. |

| Site Impact | Less on-site labor and noise; reduced waste. | More labor-intensive; higher noise and waste generation. |

| Weather Dependency | Minimal impact due to controlled environment. | Highly sensitive to weather for curing and pouring. |

Introduction to Precast and Cast-in-situ Construction

Precast construction involves manufacturing concrete elements in a controlled factory environment, ensuring consistent quality and reducing onsite labor. Cast-in-situ construction refers to pouring concrete directly at the construction site, offering greater flexibility to accommodate complex shapes and adjustments during building. Both methods have distinct advantages tailored to specific project requirements such as timeline, cost, and structural complexity.

Material Selection and Quality Control

Precast concrete involves manufacturing components in a controlled factory environment, ensuring high-quality material selection and uniform curing processes that enhance durability and strength. Cast-in-situ concrete requires on-site material selection and mixing, demanding rigorous quality control measures to maintain consistent strength and avoid defects caused by environmental variables. Effective quality control in both methods hinges on precise material testing, proper curing, and adherence to mix design specifications to optimize structural integrity and longevity.

Construction Speed and Project Timeline

Precast concrete significantly accelerates construction speed by allowing elements to be manufactured offsite simultaneously with site preparation, reducing on-site labor and curing time. Cast-in-situ concrete requires sequential processes including formwork installation, pouring, and onsite curing, extending the overall project timeline. Utilizing precast components can shorten project duration by up to 30%, optimizing schedule efficiency and minimizing delays.

Structural Performance and Durability

Precast concrete offers superior structural performance due to controlled factory conditions that enhance material quality and uniformity, resulting in higher compressive strength and load-bearing capacity. Cast-in-situ concrete allows for better structural continuity and adaptability to complex shapes but may suffer from variable onsite curing conditions that impact durability. Long-term durability in precast elements is often improved by precise mixture control and curing, while cast-in-situ structures require meticulous onsite quality control to prevent cracking and carbonation.

Cost Analysis and Budget Considerations

Precast concrete offers cost savings through reduced labor and faster construction times, minimizing on-site expenses and project delays. Cast-in-situ concrete incurs higher labor and formwork costs due to extended curing periods and increased site coordination requirements. Budget considerations favor precast for large-scale or repetitive projects where economies of scale apply, while cast-in-situ may be more economical for unique or complex structures with custom formwork needs.

Flexibility in Design and Architectural Limitations

Precast concrete offers limited flexibility in design due to its factory-made components, restricting on-site modifications and intricate architectural features. Cast-in-situ concrete allows for greater adaptability in shaping complex structures and incorporating customized designs directly at the construction site. Architectural limitations in precast elements arise from transportation and manufacturing constraints, whereas cast-in-situ facilitates seamless integration of unique architectural forms.

Labor Requirements and Skill Levels

Precast concrete requires less on-site labor due to factory-controlled production, demanding specialized skills primarily in mold preparation and quality inspection. Cast-in-situ concrete demands higher on-site labor intensity, with workers skilled in formwork assembly, mixing, pouring, and curing processes under variable conditions. Labor costs for cast-in-situ projects tend to be higher due to extended work hours and the need for versatile craftsmanship to manage site-specific challenges.

Site Constraints and Accessibility

Precast concrete components offer significant advantages in sites with limited accessibility or restricted space since they are manufactured off-site and transported ready for installation, minimizing on-site labor and equipment requirements. Cast-in-situ concrete demands ample space for formwork assembly, curing, and concrete placement, making it challenging in congested urban areas or sites with difficult terrain. Site constraints such as narrow access roads, limited staging areas, and stringent environmental regulations often favor the precast method to ensure timely construction and reduce logistical complexities.

Sustainability and Environmental Impact

Precast concrete reduces material waste and onsite energy consumption through factory-controlled production, promoting sustainability by enabling precise resource management and recycling of raw materials. Cast-in-situ concrete often results in higher carbon emissions due to extended curing times, increased use of formwork, and transportation of raw materials directly to the construction site. Implementing precast methods significantly lowers greenhouse gas emissions and minimizes construction site disturbance, enhancing environmental performance in building projects.

Applications and Suitability for Different Structures

Precast concrete is ideal for repetitive structures such as bridges, parking garages, and commercial buildings due to its factory-controlled quality and rapid installation, ensuring uniformity and reduced on-site labor. Cast-in-situ concrete offers superior flexibility for complex, custom shapes and structures like high-rise buildings and intricate architectural designs, where on-site casting allows for tailored reinforcements and connections. The choice between precast and cast-in-situ largely depends on project scale, complexity, site conditions, and construction timeline, with precast favored for speed and uniformity, and cast-in-situ excelled in adaptability and monolithic strength.

Modular Construction

Precast concrete offers faster installation and higher quality control compared to cast-in-situ methods, making it a preferred choice for modular construction projects seeking efficiency and precision.

Formwork Systems

Precast formwork systems offer faster installation and higher quality control compared to cast-in-situ formwork, which allows for greater design flexibility and on-site adaptability.

Curing Time

Precast concrete typically requires shorter curing time due to controlled factory conditions, while cast-in-situ concrete demands longer on-site curing to achieve optimal strength.

Joint Detailing

Precast concrete offers precise, factory-controlled joint detailing for enhanced durability and reduced on-site errors compared to the more variable and labor-intensive joint finishing required in cast-in-situ concrete.

Tolerance Control

Precast concrete offers superior tolerance control due to factory conditions and precision molds, reducing construction errors compared to variable on-site cast-in-situ methods.

Factory Fabrication

Factory fabrication of precast concrete enables precise quality control, faster production, and reduced labor costs compared to the on-site mixing and curing required in cast-in-situ concrete.

Site Assembly

Precast concrete enables faster site assembly with factory-controlled quality and minimal on-site labor compared to the more time-consuming and labor-intensive cast-in-situ method requiring extensive formwork and curing on site.

Concrete Segmentation

Precast concrete offers controlled factory conditions for precise segmentation and faster assembly, whereas cast-in-situ concrete allows flexible on-site segmentation tailored to complex structural designs.

Transport Logistics

Precast concrete requires careful transport logistics including load securing, route planning, and handling equipment, while cast-in-situ concrete reduces transportation needs but demands onsite formwork and material staging management.

Quality Assurance

Precast concrete offers superior quality assurance through factory-controlled conditions and consistent production standards compared to cast-in-situ concrete, which is more susceptible to on-site variability.

Precast vs Cast-in-situ Infographic

njnir.com

njnir.com