Cold recycling in civil engineering involves the reuse of existing pavement materials without heating, which reduces energy consumption and emissions compared to hot recycling. Hot recycling heats asphalt materials to high temperatures to allow thorough mixing and reapplication, offering enhanced durability and performance in road construction. Choosing between cold and hot recycling depends on project requirements, environmental considerations, and desired pavement lifespan.

Table of Comparison

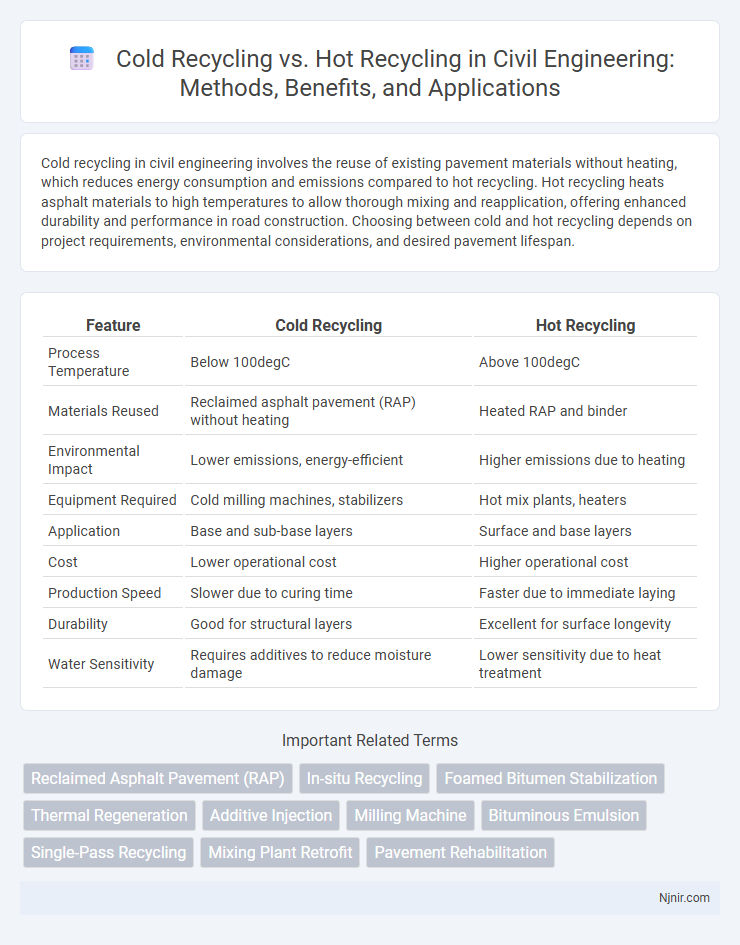

| Feature | Cold Recycling | Hot Recycling |

|---|---|---|

| Process Temperature | Below 100degC | Above 100degC |

| Materials Reused | Reclaimed asphalt pavement (RAP) without heating | Heated RAP and binder |

| Environmental Impact | Lower emissions, energy-efficient | Higher emissions due to heating |

| Equipment Required | Cold milling machines, stabilizers | Hot mix plants, heaters |

| Application | Base and sub-base layers | Surface and base layers |

| Cost | Lower operational cost | Higher operational cost |

| Production Speed | Slower due to curing time | Faster due to immediate laying |

| Durability | Good for structural layers | Excellent for surface longevity |

| Water Sensitivity | Requires additives to reduce moisture damage | Lower sensitivity due to heat treatment |

Introduction to Road Recycling Methods

Cold recycling and hot recycling are key methods in road rehabilitation that focus on reusing existing pavement materials to reduce costs and environmental impact. Cold recycling involves reclaiming and processing asphalt without heating, typically used for surface and base layers, offering energy savings and lower emissions. Hot recycling heats reclaimed asphalt pavement (RAP) to restore its properties, providing improved durability and performance for high-traffic roads.

Overview of Cold Recycling in Pavement

Cold recycling in pavement involves the process of reclaiming and reusing asphalt pavement materials at ambient temperatures, reducing the need for new aggregates and bitumen. This method enhances sustainability by lowering energy consumption and greenhouse gas emissions compared to traditional hot recycling, which requires heating materials to high temperatures. Cold recycling techniques, including in-place or plant-mixing processes, improve cost efficiency and minimize environmental impact while maintaining pavement durability.

Key Processes in Hot Recycling

Hot recycling in pavement rehabilitation involves heating old asphalt to soften it, allowing for thorough mixing with new binder and aggregates, which enhances the recycled material's durability and performance. The process includes heating, milling, mixing, and paving, ensuring the reclaimed asphalt mixture is rejuvenated and structurally sound. This method contrasts with cold recycling, where the asphalt is processed without heating, relying on chemical additives for rejuvenation.

Material Requirements: Cold vs Hot Recycling

Cold recycling requires less energy as it processes asphalt pavement at ambient temperatures, preserving existing binder and aggregate quality while minimizing the need for new materials. Hot recycling involves reheating reclaimed asphalt pavement (RAP) to high temperatures, which can degrade binder properties and often necessitates the addition of virgin binder and aggregates to restore mix performance. Consequently, cold recycling is more material-efficient and environmentally sustainable, reducing the demand for fresh resources compared to hot recycling methods.

Equipment Used in Each Recycling Method

Cold recycling equipment primarily includes specialized milling machines, stabilizers, and compactors designed to process in-place asphalt without heating, facilitating the treatment of base layers with minimal energy consumption. Hot recycling employs heated asphalt heaters, mixers, and pugmills combined with traditional asphalt pavers and compactors to reprocess reclaimed asphalt pavement (RAP) at elevated temperatures for enhanced material blending. Both methods require precise temperature control and compatible machinery to optimize the rejuvenation of recycled materials and ensure pavement durability.

Environmental Impact Comparison

Cold recycling significantly reduces energy consumption by reusing asphalt materials without the need for heating, resulting in lower greenhouse gas emissions compared to hot recycling, which involves reheating asphalt aggregates at temperatures around 300degC. Cold recycling minimizes the release of volatile organic compounds (VOCs) and pollutants, making it a more eco-friendly option for pavement rehabilitation. While hot recycling can offer enhanced material performance, the environmental trade-offs include higher fossil fuel use and increased carbon footprint.

Cost Efficiency Analysis

Cold recycling reduces costs by reusing existing pavement materials without the need for heating, resulting in lower energy consumption and minimized fuel expenses compared to hot recycling. Hot recycling incurs higher operational costs due to the energy-intensive heating process required to soften asphalt materials, increasing fuel consumption and equipment wear. Overall, cold recycling offers a more cost-effective solution for pavement rehabilitation, especially in large-scale projects aiming to optimize budget allocation and reduce environmental impact.

Performance and Durability of Recycled Pavements

Cold recycling uses in-place materials at ambient temperatures, resulting in lower energy consumption and reduced emissions, but it may yield slightly lower initial strength compared to hot recycling methods. Hot recycling involves heating asphalt at high temperatures, enhancing binder activation and leading to improved early performance and load-bearing capacity. Over time, hot recycled pavements generally exhibit superior durability and resistance to deformation, while cold recycled pavements benefit from environmental sustainability and quicker construction cycles.

Project Suitability: When to Choose Cold or Hot Recycling

Cold recycling suits projects prioritizing sustainability and cost efficiency, especially for rehabilitating damaged asphalt pavements without complete removal. Hot recycling is best for extensive pavement failures requiring full-depth repairs, offering superior material bonding through high temperatures. Selecting between methods depends on pavement condition, project scale, budget constraints, and environmental impact goals.

Future Trends in Pavement Recycling Technologies

Future trends in pavement recycling technologies emphasize increased adoption of cold recycling methods due to their lower energy consumption and reduced greenhouse gas emissions compared to traditional hot recycling. Innovations in additives and foamed bitumen improve the strength and durability of cold recycled layers, making them competitive with hot mix asphalt. Integration of smart sensors and machine learning optimizes the recycling process, enabling precise control over material properties and enhancing pavement lifecycle performance.

Reclaimed Asphalt Pavement (RAP)

Cold recycling of Reclaimed Asphalt Pavement (RAP) uses in-place processing with emulsions or foamed asphalt at ambient temperatures, reducing energy consumption, whereas hot recycling heats RAP to high temperatures for mixing, enhancing binder activation but increasing emissions.

In-situ Recycling

In-situ cold recycling preserves existing pavement materials by processing and reusing them on-site at ambient temperatures, reducing energy consumption and emissions compared to hot recycling methods that require heating asphalt mixtures.

Foamed Bitumen Stabilization

Foamed Bitumen Stabilization enhances cold recycling by improving the mechanical properties and durability of reclaimed asphalt layers without the high energy consumption and emissions associated with hot recycling.

Thermal Regeneration

Thermal regeneration in hot recycling uses high temperatures to restore asphalt binder properties, enhancing pavement longevity compared to the lower-energy, less intensive binder restoration in cold recycling.

Additive Injection

Additive injection in cold recycling enhances material properties at lower temperatures, reducing energy consumption and emissions compared to hot recycling processes.

Milling Machine

Cold recycling utilizes milling machines to reclaim asphalt layers without heating, preserving material quality and reducing energy consumption compared to the heat-intensive process of hot recycling.

Bituminous Emulsion

Bituminous emulsion in cold recycling offers improved workability and environmental benefits by enabling lower temperature processing compared to hot recycling, which relies on reheating bitumen at high temperatures for pavement rehabilitation.

Single-Pass Recycling

Single-pass cold recycling for asphalt pavement reduces energy consumption by reusing milled materials on-site at ambient temperatures, unlike hot recycling which involves reheating and melting, leading to higher emissions and costs.

Mixing Plant Retrofit

Cold recycling in mixing plant retrofits reduces energy consumption by reusing reclaimed asphalt at ambient temperatures, while hot recycling requires extensive heating processes that increase operational costs and emissions.

Pavement Rehabilitation

Cold recycling in pavement rehabilitation reduces energy consumption and emissions by reusing existing materials at ambient temperatures, whereas hot recycling involves heating asphalt mixtures, offering faster curing but higher energy costs.

cold recycling vs hot recycling Infographic

njnir.com

njnir.com