Green concrete incorporates industrial by-products like fly ash and slag to reduce carbon emissions and enhance sustainability compared to conventional concrete. It offers improved durability, lower permeability, and better resistance to chemical attacks, making it ideal for eco-friendly construction projects. Adopting green concrete significantly decreases the environmental impact of infrastructure development without compromising structural integrity.

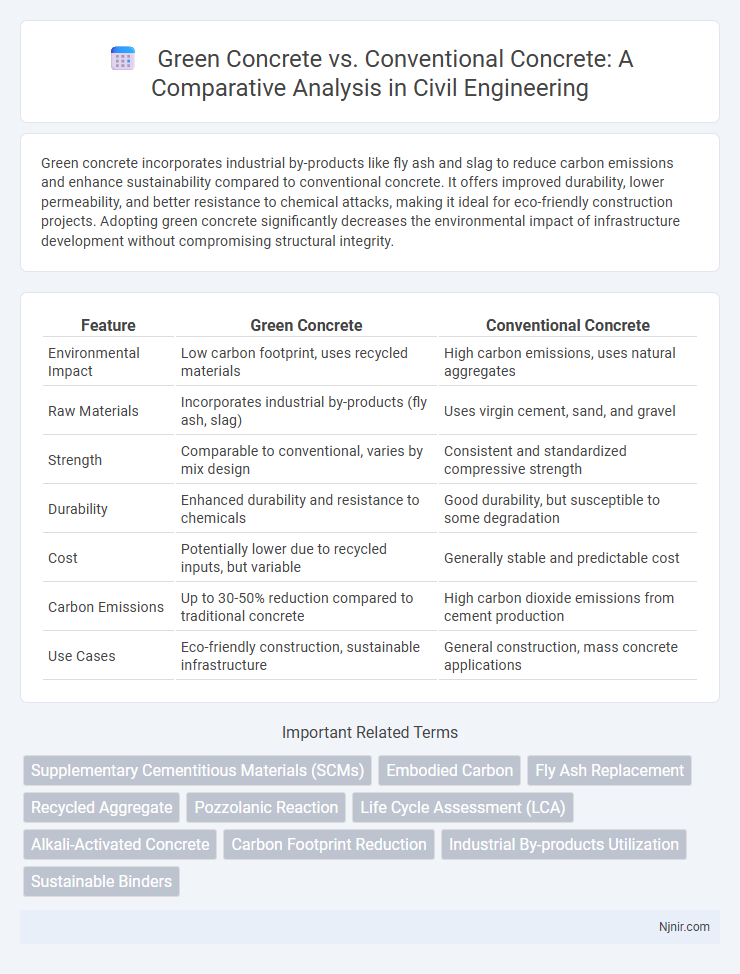

Table of Comparison

| Feature | Green Concrete | Conventional Concrete |

|---|---|---|

| Environmental Impact | Low carbon footprint, uses recycled materials | High carbon emissions, uses natural aggregates |

| Raw Materials | Incorporates industrial by-products (fly ash, slag) | Uses virgin cement, sand, and gravel |

| Strength | Comparable to conventional, varies by mix design | Consistent and standardized compressive strength |

| Durability | Enhanced durability and resistance to chemicals | Good durability, but susceptible to some degradation |

| Cost | Potentially lower due to recycled inputs, but variable | Generally stable and predictable cost |

| Carbon Emissions | Up to 30-50% reduction compared to traditional concrete | High carbon dioxide emissions from cement production |

| Use Cases | Eco-friendly construction, sustainable infrastructure | General construction, mass concrete applications |

Introduction to Green Concrete and Conventional Concrete

Green concrete incorporates industrial waste materials like fly ash, slag, and recycled aggregates to reduce environmental impact and carbon footprint during production. Conventional concrete primarily consists of cement, water, sand, and gravel, relying on Portland cement which contributes significantly to CO2 emissions. The adoption of green concrete addresses sustainability by enhancing durability and reducing resource consumption compared to traditional concrete formulations.

Composition and Materials Used

Green concrete incorporates recycled materials such as fly ash, slag, and recycled aggregates, reducing reliance on traditional cement and natural aggregates, which lowers carbon emissions and environmental impact. Conventional concrete primarily uses Portland cement, natural sand, and coarse aggregates, contributing significantly to CO2 emissions during cement production. The incorporation of supplementary cementitious materials and industrial by-products in green concrete enhances sustainability while maintaining structural integrity.

Environmental Impact Assessment

Green concrete significantly reduces carbon dioxide emissions by utilizing industrial by-products like fly ash and slag, lowering the reliance on Portland cement, a major contributor to greenhouse gases. Its production consumes less energy and incorporates recycled materials, decreasing landfill waste and resource depletion compared to conventional concrete. Environmental impact assessments reveal that green concrete offers improved sustainability through reduced embodied energy and enhanced durability, making it a superior choice for eco-friendly construction.

Mechanical Properties Comparison

Green concrete exhibits comparable compressive strength to conventional concrete, with some mixtures achieving up to 95% of traditional concrete's strength due to the incorporation of recycled materials and supplementary cementitious substances like fly ash and slag. Its tensile strength and flexural performance can vary depending on the specific additives and curing methods but generally maintain adequate levels for structural applications. While green concrete often shows enhanced durability and resistance to chemical attacks, tensile strength improvements remain a key research focus to match or exceed conventional concrete standards.

Durability and Longevity

Green concrete incorporates supplementary cementitious materials like fly ash and slag, enhancing durability by reducing permeability and increasing resistance to chemical attacks compared to conventional concrete. Its improved microstructure mitigates cracking and extends lifespan under harsh environmental conditions, making it highly suitable for sustainable infrastructure projects. Studies show green concrete can achieve comparable or superior longevity to traditional concrete, supporting reduced maintenance and lifecycle costs.

Cost Efficiency and Economic Analysis

Green concrete offers improved cost efficiency over conventional concrete by utilizing industrial by-products like fly ash and slag, which reduce material expenses and landfill fees. Life cycle cost analysis reveals that despite higher initial production costs, green concrete lowers long-term maintenance and environmental compliance costs, enhancing overall economic viability. Studies indicate a 15-25% reduction in total project costs when incorporating green concrete due to energy savings and reduced carbon taxes.

Workability and Application Methods

Green concrete exhibits comparable or improved workability compared to conventional concrete due to the use of supplementary cementitious materials like fly ash, slag, and recycled aggregates, which enhance plasticity and reduce water demand. Application methods for green concrete largely mirror those of conventional concrete, enabling seamless integration into existing construction processes, with adjustments primarily in curing techniques to optimize strength development and durability. Advances in admixtures and mix design further ensure green concrete meets rigorous performance standards while promoting sustainability in infrastructure projects.

Energy Consumption and Carbon Footprint

Green concrete significantly reduces energy consumption by utilizing industrial by-products like fly ash and slag, which require less processing compared to the cement used in conventional concrete. The carbon footprint of green concrete is notably lower due to diminished clinker content, resulting in decreased CO2 emissions during production. This sustainable alternative supports energy efficiency and environmental conservation while maintaining comparable structural performance to traditional concrete.

Regulatory Standards and Certifications

Green concrete must comply with evolving regulatory standards such as LEED (Leadership in Energy and Environmental Design) and ASTM International guidelines that emphasize sustainability and reduced carbon footprint. Conventional concrete adheres primarily to traditional ASTM and ACI (American Concrete Institute) standards focusing on strength and durability without mandatory environmental criteria. Certifications like BREEAM and Envision further validate green concrete's environmental performance, driving wider adoption in eco-conscious construction projects.

Future Prospects and Industry Adoption

Green concrete, incorporating recycled materials and low-carbon binders, offers promising future prospects by significantly reducing greenhouse gas emissions in construction. Industry adoption is accelerating as governments enforce stricter environmental regulations and demand sustainable building practices increase worldwide. Innovations in mix design and scalability improvements position green concrete as a competitive alternative to conventional concrete in large-scale infrastructure projects.

Supplementary Cementitious Materials (SCMs)

Green concrete incorporates Supplementary Cementitious Materials (SCMs) like fly ash, slag, and silica fume to reduce cement usage, enhance durability, and lower carbon emissions compared to conventional concrete.

Embodied Carbon

Green concrete reduces embodied carbon by incorporating recycled materials and alternative binders, significantly lowering CO2 emissions compared to conventional concrete made primarily with Portland cement.

Fly Ash Replacement

Fly ash replacement in green concrete reduces carbon emissions and enhances durability compared to conventional concrete, making it an eco-friendly and sustainable construction material.

Recycled Aggregate

Recycled aggregate in green concrete significantly reduces environmental impact by replacing natural aggregates, enhancing sustainability without compromising structural integrity compared to conventional concrete.

Pozzolanic Reaction

Green concrete utilizes pozzolanic materials such as fly ash and silica fume to enhance the pozzolanic reaction, resulting in improved durability and reduced carbon footprint compared to conventional concrete.

Life Cycle Assessment (LCA)

Green concrete reduces environmental impact by lowering carbon emissions and energy consumption throughout its Life Cycle Assessment compared to conventional concrete.

Alkali-Activated Concrete

Alkali-activated green concrete reduces carbon emissions by utilizing industrial byproducts like fly ash and slag, offering superior durability and environmental benefits compared to conventional Portland cement concrete.

Carbon Footprint Reduction

Green concrete reduces carbon footprint by incorporating recycled materials and industrial by-products, resulting in up to 40% lower CO2 emissions compared to conventional concrete.

Industrial By-products Utilization

Green concrete utilizes industrial by-products such as fly ash and slag to reduce cement consumption and lower carbon emissions compared to conventional concrete.

Sustainable Binders

Green concrete utilizes sustainable binders such as fly ash, slag, and geopolymer cement to reduce carbon emissions and enhance environmental performance compared to conventional concrete's traditional Portland cement.

Green Concrete vs Conventional Concrete Infographic

njnir.com

njnir.com