Pervious concrete offers superior stormwater management by allowing water to infiltrate through its porous structure, reducing runoff and promoting groundwater recharge compared to traditional concrete paving. Its open-graded composition significantly decreases surface water accumulation, minimizing the risk of flooding and erosion in urban areas. Traditional concrete, while stronger and more durable under heavy loads, often results in increased surface water runoff and environmental stress due to its impermeable nature.

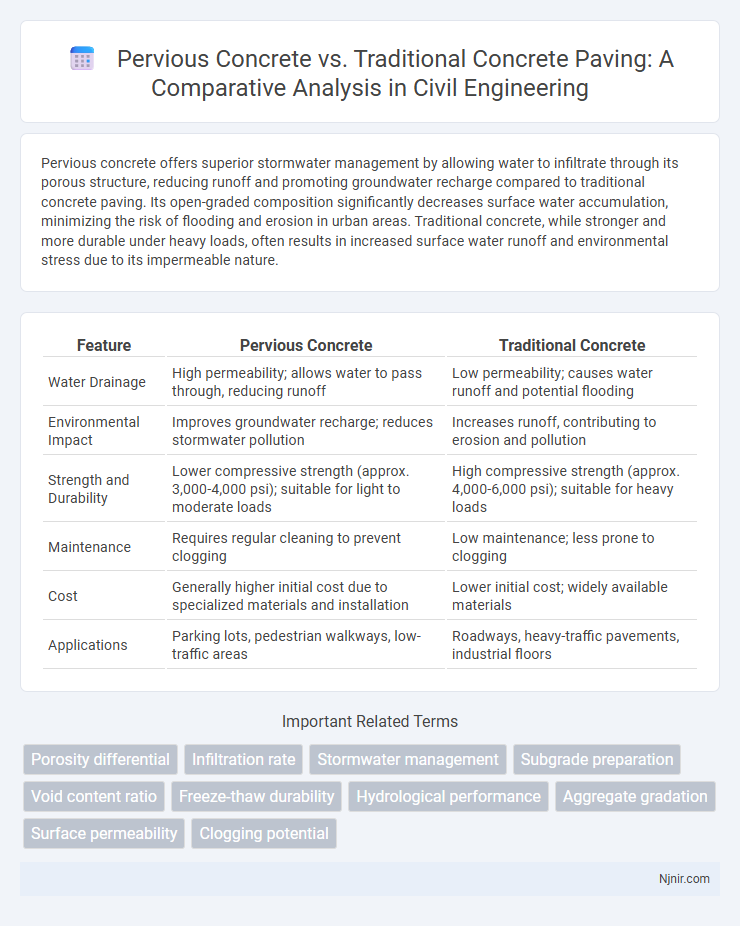

Table of Comparison

| Feature | Pervious Concrete | Traditional Concrete |

|---|---|---|

| Water Drainage | High permeability; allows water to pass through, reducing runoff | Low permeability; causes water runoff and potential flooding |

| Environmental Impact | Improves groundwater recharge; reduces stormwater pollution | Increases runoff, contributing to erosion and pollution |

| Strength and Durability | Lower compressive strength (approx. 3,000-4,000 psi); suitable for light to moderate loads | High compressive strength (approx. 4,000-6,000 psi); suitable for heavy loads |

| Maintenance | Requires regular cleaning to prevent clogging | Low maintenance; less prone to clogging |

| Cost | Generally higher initial cost due to specialized materials and installation | Lower initial cost; widely available materials |

| Applications | Parking lots, pedestrian walkways, low-traffic areas | Roadways, heavy-traffic pavements, industrial floors |

Introduction to Pervious and Traditional Concrete

Pervious concrete is engineered to allow water to pass through its porous structure, reducing runoff and enhancing groundwater recharge, making it ideal for sustainable paving solutions. Traditional concrete is a dense, impermeable mixture of cement, aggregates, and water, providing a solid, durable surface widely used in roads, sidewalks, and driveways. Pervious concrete typically has a higher void content of 15-25%, while traditional concrete has less than 5%, impacting their water permeability and environmental applications.

Key Material Differences

Pervious concrete differs from traditional concrete primarily in its aggregate composition and water-to-cement ratio, featuring larger, uniformly graded coarse aggregates and reduced fine particles to create interconnected voids for water permeability. The mix design of pervious concrete includes less cement paste and minimal sand, enhancing its porosity compared to the dense, tightly packed matrix of traditional concrete that maximizes strength and durability. Material selection for pervious concrete focuses on achieving a balance between structural integrity and permeability, crucial for sustainable urban drainage systems, while traditional concrete emphasizes compressive strength and surface smoothness for long-lasting pavements.

Permeability and Drainage Capabilities

Pervious concrete provides superior permeability and drainage capabilities compared to traditional concrete paving by allowing water to pass through its porous structure, reducing runoff and promoting groundwater recharge. This enhanced permeability helps prevent water pooling and decreases the risk of flooding in paved areas. In contrast, traditional concrete has a dense, impermeable surface that directs water away, often necessitating additional drainage systems.

Structural Strength Comparison

Pervious concrete exhibits lower compressive strength, typically ranging from 2,500 to 4,000 psi, compared to traditional concrete which often exceeds 4,000 psi, making it less suitable for heavy structural loads. Traditional concrete's dense matrix provides superior durability and load-bearing capacity essential for highways and industrial pavements. However, pervious concrete's porous structure excels in stormwater management but requires design consideration to maintain adequate structural performance in pavement applications.

Environmental Impact and Sustainability

Pervious concrete significantly reduces runoff by allowing water to infiltrate through its porous structure, promoting groundwater recharge and minimizing erosion compared to traditional concrete paving. The use of pervious concrete mitigates urban heat island effects due to its higher reflectivity and porosity, enhancing local microclimates and reducing energy consumption for cooling. Its sustainable benefits include lowering stormwater treatment costs and supporting LEED certification, positioning it as an environmentally responsible choice for paving projects.

Installation Processes and Techniques

Pervious concrete installation requires careful layering and compaction to maintain its porous structure, allowing water to pass through, unlike traditional concrete which demands dense mixing and vibration for strength and uniformity. The installation of pervious concrete involves avoiding excessive water in the mix to prevent clogging the pores, whereas traditional concrete typically includes a higher water-cement ratio for workability. Proper curing methods for pervious concrete focus on preserving permeability, while traditional concrete curing emphasizes maximizing compressive strength and durability.

Maintenance and Longevity

Pervious concrete offers superior drainage capabilities, significantly reducing surface water accumulation and lowering the risk of freeze-thaw damage, which enhances its longevity compared to traditional concrete paving. Maintenance for pervious concrete primarily involves regular vacuuming or power washing to prevent clogging and maintain permeability, whereas traditional concrete requires sealing and crack repairs to prevent water infiltration and structural deterioration. While traditional concrete often necessitates more frequent repairs due to surface wear and cracking, pervious concrete's durability in managing stormwater extends its service life when properly maintained.

Cost Analysis and Economic Considerations

Pervious concrete generally incurs higher initial costs than traditional concrete due to specialized materials and installation techniques, averaging 15-25% more per square foot. However, economic considerations favor pervious concrete through reduced stormwater management expenses, potential regulatory incentives, and lower long-term maintenance costs related to drainage infrastructure. Life-cycle cost analysis indicates that despite upfront investments, pervious concrete can deliver significant savings and environmental benefits over a 20-30 year period.

Ideal Applications and Use Cases

Pervious concrete excels in applications requiring stormwater management, such as parking lots, sidewalks, and low-traffic roadways, by allowing water infiltration and reducing runoff. Traditional concrete is ideal for high-load infrastructure like highways, airport runways, and heavy industrial floors due to its superior compressive strength and durability. Choosing between pervious and traditional concrete depends on balancing permeability needs with structural demands in specific paving projects.

Future Trends in Concrete Paving Technologies

Pervious concrete is gaining traction as a sustainable solution in concrete paving due to its ability to manage stormwater and reduce urban heat islands, aligning with future infrastructure resilience goals. Innovations in admixtures and fiber reinforcement are enhancing the durability and load-bearing capacity of pervious concrete, making it a viable alternative to traditional concrete in heavy-traffic areas. Emerging technologies such as smart sensors embedded in concrete are expected to monitor pavement health in real-time, optimizing maintenance and extending the lifespan of both pervious and traditional concrete pavements.

Porosity differential

Pervious concrete features a porosity of 15-25% that allows water infiltration, whereas traditional concrete typically has less than 5% porosity, resulting in significantly reduced permeability and increased runoff.

Infiltration rate

Pervious concrete exhibits an infiltration rate of 0.5 to 5 inches per second, vastly outperforming traditional concrete paving, which typically has negligible permeability and minimal water infiltration capacity.

Stormwater management

Pervious concrete enhances stormwater management by allowing rapid infiltration and reducing runoff, whereas traditional concrete increases surface runoff and potential flooding risks.

Subgrade preparation

Pervious concrete paving requires a well-compacted, uniformly graded, and free-draining subgrade to maximize infiltration, whereas traditional concrete paving demands a stable, fully compacted subgrade to support load-bearing and prevent settlement.

Void content ratio

Pervious concrete typically has a void content ratio of 15-25%, significantly higher than traditional concrete's near 0%, enabling superior water permeability and stormwater management.

Freeze-thaw durability

Pervious concrete exhibits superior freeze-thaw durability compared to traditional concrete paving due to its enhanced drainage properties that reduce water retention and subsequent freeze-induced damage.

Hydrological performance

Pervious concrete significantly improves hydrological performance by enhancing stormwater infiltration and reducing surface runoff compared to traditional concrete paving.

Aggregate gradation

Pervious concrete uses a single-sized coarse aggregate with minimal fine aggregate to maximize void spaces for water permeability, while traditional concrete employs a well-graded aggregate mix with a balanced range of particle sizes to achieve maximum density and strength.

Surface permeability

Pervious concrete features high surface permeability that allows water infiltration and reduces runoff, while traditional concrete paving is dense and impermeable, causing surface water accumulation.

Clogging potential

Pervious concrete has a higher clogging potential due to its porous structure that traps debris and sediments, while traditional concrete's dense composition minimizes clogging but reduces permeability.

Pervious concrete vs Traditional concrete paving Infographic

njnir.com

njnir.com