Cementitious grouting uses a water-cement mixture to fill voids and reinforce soil, offering high compressive strength and durability ideal for structural stabilization. Chemical grouting employs reactive fluids like polyurethane or silicates that penetrate fine soil particles, enhancing soil cohesion and reducing permeability. Choosing between these methods depends on soil type, project requirements, and environmental conditions to ensure optimal ground improvement.

Table of Comparison

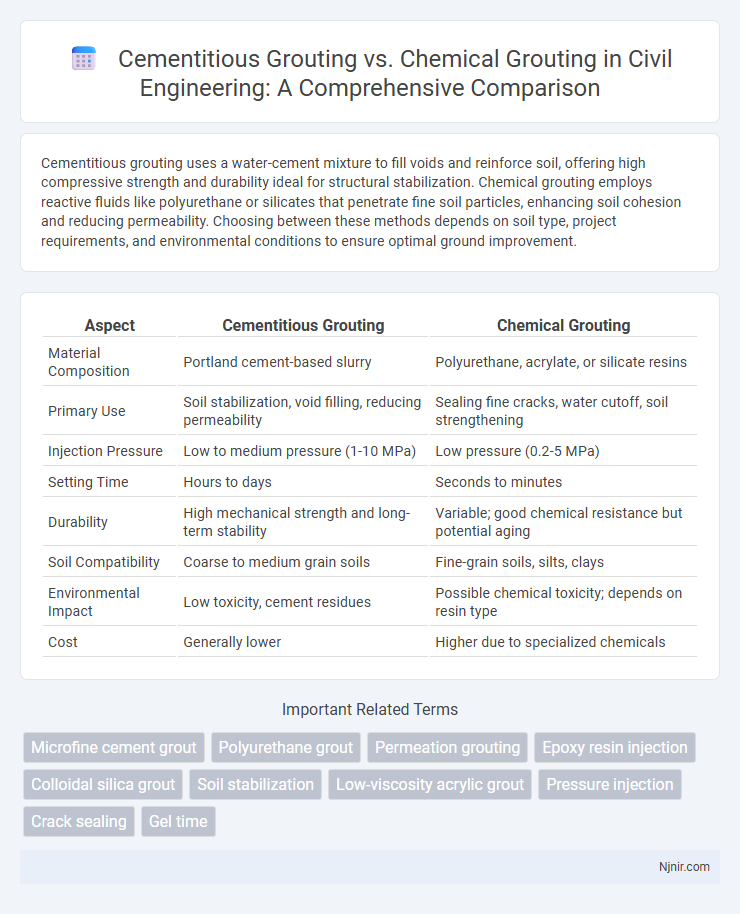

| Aspect | Cementitious Grouting | Chemical Grouting |

|---|---|---|

| Material Composition | Portland cement-based slurry | Polyurethane, acrylate, or silicate resins |

| Primary Use | Soil stabilization, void filling, reducing permeability | Sealing fine cracks, water cutoff, soil strengthening |

| Injection Pressure | Low to medium pressure (1-10 MPa) | Low pressure (0.2-5 MPa) |

| Setting Time | Hours to days | Seconds to minutes |

| Durability | High mechanical strength and long-term stability | Variable; good chemical resistance but potential aging |

| Soil Compatibility | Coarse to medium grain soils | Fine-grain soils, silts, clays |

| Environmental Impact | Low toxicity, cement residues | Possible chemical toxicity; depends on resin type |

| Cost | Generally lower | Higher due to specialized chemicals |

Introduction to Cementitious and Chemical Grouting

Cementitious grouting involves injecting a mixture of water, cement, and additives into soil or cracks to improve strength and reduce permeability, commonly used in foundation repair and soil stabilization. Chemical grouting uses specialized chemical solutions such as sodium silicate or polyurethane to permeate fine soils, offering faster setting times and superior control in sealing leaks or strengthening delicate ground conditions. Both methods enhance structural integrity, with cementitious grouting preferred for coarse soils and large voids, while chemical grouting excels in fine-grained soils and precise applications.

Key Differences Between Cementitious and Chemical Grouting

Cementitious grouting utilizes a mixture of cement, water, and additives to fill voids and strengthen soil through hydraulic mechanisms, providing high compressive strength and durability in structural foundations. Chemical grouting employs specialized chemicals such as polyurethane, acrylates, or silicates to penetrate fine soils and create flexible, low-permeability seals by polymerization or gelation, suitable for water cut-off and soil stabilization in sensitive environments. Key differences include material composition, penetration ability in varying soil types, curing time, environmental impact, and application techniques, with cementitious grouts favoring coarse soils and structural reinforcement, while chemical grouts are preferred for fine or contaminated soils requiring minimal disturbance.

Material Composition and Properties

Cementitious grouting primarily uses a mixture of cement, water, and fine aggregates, providing high compressive strength and excellent durability for soil stabilization and structural repairs. Chemical grouting involves polymers or resin-based materials that offer rapid setting times, low viscosity for deep soil penetration, and flexibility in adapting to varying ground conditions. The choice between these grouting materials depends on factors such as permeability, required strength, and environmental conditions at the construction site.

Application Methods and Techniques

Cementitious grouting involves injecting a mixture of cement, water, and additives into soil or rock to improve stability and reduce permeability, commonly applied via pressure grouting or compaction grouting techniques. Chemical grouting uses chemical solutions like silicates, acrylates, or polyurethane injected into voids, cracks, or porous soil to create a gel or solidified mass, employing permeation and curtain grouting methods to control ground movement and seepage. Both techniques require precise pressure control and injection rates tailored to site conditions and soil types for effective ground improvement and structural support.

Suitability for Various Soil Conditions

Cementitious grouting is highly suitable for permeable soils like sands and gravels due to its ability to fill larger voids and stabilize loose particles effectively. Chemical grouting excels in fine-grained soils such as silts and clays by penetrating smaller pores and creating a flexible, impermeable barrier that enhances soil strength and reduces permeability. Each method's effectiveness depends on soil permeability, grain size, and the desired rigidity or flexibility of the ground improvement.

Strength and Durability Comparison

Cementitious grouting offers high compressive strength and excellent durability due to its cement-based composition, making it ideal for structural repairs and heavy load-bearing applications. Chemical grouting provides superior penetration into fine cracks and soil particles, but its strength and long-term durability may vary depending on the specific chemical formulation used. In terms of resistance to environmental factors such as moisture and chemical exposure, cementitious grouting generally outperforms chemical grouting, ensuring longer-lasting performance in demanding conditions.

Cost Implications and Budget Considerations

Cementitious grouting generally offers a lower initial material cost compared to chemical grouting, making it a preferred choice for large-scale projects with tight budget constraints. Chemical grouting, although more expensive due to specialized resins and injection equipment, provides enhanced soil stabilization and durability that can reduce long-term maintenance expenses. Budget considerations should account for project scale, soil conditions, and performance requirements to determine the most cost-effective grouting method.

Environmental Impact and Safety Concerns

Cementitious grouting generates minimal volatile organic compounds (VOCs) and uses non-toxic materials, making it environmentally safer and posing lower health risks during application. Chemical grouting often contains synthetic resins and toxic monomers that can leach harmful substances into soil and groundwater, raising environmental contamination concerns. Proper ventilation and protective equipment are essential when handling chemical grouts to mitigate inhalation hazards and skin exposure.

Typical Use Cases in Civil Engineering Projects

Cementitious grouting is typically used for soil stabilization, void filling, and underpinning foundations in civil engineering because of its high compressive strength and low cost. Chemical grouting is preferred for projects requiring ground water control, soil improvement in sandy or granular soils, and creating impermeable barriers due to its ability to penetrate fine soil particles and rapid setting properties. Both methods are essential in tunneling, foundation repair, and slope stabilization, depending on site-specific soil conditions and project requirements.

Selection Criteria: Choosing the Right Grouting Method

Selection of the right grouting method depends on soil type, project requirements, and environmental conditions; cementitious grouting suits coarse soils and applications requiring high compressive strength, while chemical grouting excels in fine soils and situations demanding minimal permeability and rapid setting times. Cementitious grouts offer durability and cost-effectiveness in large void fillings, whereas chemical grouts provide superior penetration and flexibility for intricate soil stabilization. Evaluating factors such as soil permeability, load-bearing capacity, and project timeline ensures optimal performance and long-term stability.

Microfine cement grout

Microfine cement grout in cementitious grouting offers superior permeability control and long-term durability compared to chemical grouting, making it ideal for stabilizing weakened soils and reducing water seepage in construction projects.

Polyurethane grout

Polyurethane grout, a key chemical grouting material, offers superior water resistance, flexibility, and fast curing compared to traditional cementitious grouting, making it ideal for sealing leaks and stabilizing soils in diverse construction applications.

Permeation grouting

Permeation grouting using cementitious materials enhances soil strength by filling voids with a cement-based slurry, while chemical grouting employs low-viscosity chemical solutions to penetrate finer soils, offering more precise control over permeability and stabilization.

Epoxy resin injection

Epoxy resin injection in chemical grouting provides superior adhesion, high tensile strength, and excellent chemical resistance compared to cementitious grouting, making it ideal for structural repairs and sealing fine cracks.

Colloidal silica grout

Colloidal silica grout, a type of chemical grouting, offers superior permeability reduction and soil stabilization compared to traditional cementitious grouting by filling fine pores with nanoscale silica particles.

Soil stabilization

Cementitious grouting enhances soil stabilization by increasing soil strength and reducing permeability through the injection of cement-based materials, while chemical grouting improves soil stability by introducing chemical solutions that solidify and bind soil particles for increased cohesion and reduced water flow.

Low-viscosity acrylic grout

Low-viscosity acrylic grout in chemical grouting offers superior penetration and durability compared to traditional cementitious grouting, making it ideal for sealing fine cracks and stabilizing soils with minimal disruption.

Pressure injection

Pressure injection in cementitious grouting provides superior mechanical strength and durability compared to the rapid-setting and flexible properties of chemical grouting.

Crack sealing

Cementitious grouting effectively seals larger cracks by filling voids with a durable, cement-based material, while chemical grouting penetrates fine cracks and provides enhanced adhesion and flexibility using polymer or resin-based injectables.

Gel time

Cementitious grouting typically has a longer gel time ranging from 30 minutes to several hours, whereas chemical grouting features adjustable gel times from seconds to minutes for faster setting and controlled penetration.

cementitious grouting vs chemical grouting Infographic

njnir.com

njnir.com