Fiber Reinforced Polymer (FRP) offers superior resistance to corrosion compared to traditional steel reinforcement, significantly extending the lifespan of concrete structures in aggressive environments. FRP's lightweight properties reduce transportation and installation costs, while its high tensile strength provides adequate load-bearing capacity. However, steel reinforcement remains favored for its ductility and well-established performance, especially in seismic applications.

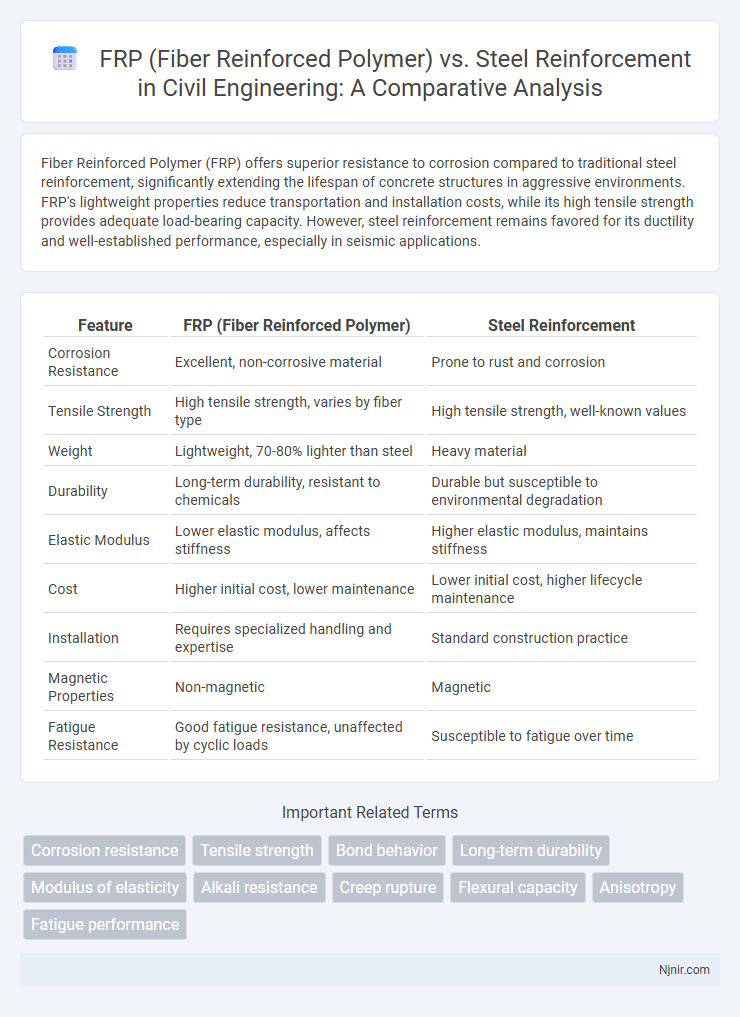

Table of Comparison

| Feature | FRP (Fiber Reinforced Polymer) | Steel Reinforcement |

|---|---|---|

| Corrosion Resistance | Excellent, non-corrosive material | Prone to rust and corrosion |

| Tensile Strength | High tensile strength, varies by fiber type | High tensile strength, well-known values |

| Weight | Lightweight, 70-80% lighter than steel | Heavy material |

| Durability | Long-term durability, resistant to chemicals | Durable but susceptible to environmental degradation |

| Elastic Modulus | Lower elastic modulus, affects stiffness | Higher elastic modulus, maintains stiffness |

| Cost | Higher initial cost, lower maintenance | Lower initial cost, higher lifecycle maintenance |

| Installation | Requires specialized handling and expertise | Standard construction practice |

| Magnetic Properties | Non-magnetic | Magnetic |

| Fatigue Resistance | Good fatigue resistance, unaffected by cyclic loads | Susceptible to fatigue over time |

Introduction to Reinforcement Materials in Civil Engineering

Fiber Reinforced Polymer (FRP) and steel reinforcement are pivotal materials in civil engineering, each offering distinct properties for structural enhancement. FRP provides corrosion resistance, high strength-to-weight ratio, and electromagnetic neutrality, making it ideal for bridges, marine structures, and seismic retrofitting. Steel reinforcement, characterized by its ductility, proven performance, and cost-effectiveness, remains essential for load-bearing applications and conventional reinforced concrete construction.

Overview of FRP (Fiber Reinforced Polymer)

Fiber Reinforced Polymer (FRP) offers significant advantages over traditional steel reinforcement, including high strength-to-weight ratio, corrosion resistance, and electromagnetic neutrality. FRP composites, typically made from carbon, glass, or aramid fibers embedded in a polymer matrix, provide superior durability in harsh environments, extending the service life of concrete structures. Their lightweight nature reduces transportation and handling costs, making FRP an increasingly preferred material in infrastructure applications such as bridges, marine structures, and seismic retrofitting.

Steel Reinforcement: Properties and Applications

Steel reinforcement offers high tensile strength, excellent ductility, and proven bonding characteristics with concrete, making it ideal for structural applications requiring load-bearing capacity. Its cost-effectiveness and widespread availability support extensive use in bridges, buildings, and infrastructure projects where durability and reliability are critical. Corrosion resistance can be enhanced through protective coatings and treatments, extending the lifespan of steel reinforcement in aggressive environments.

Mechanical Performance Comparison: FRP vs Steel

Fiber Reinforced Polymer (FRP) rebars exhibit high tensile strength, corrosion resistance, and a lightweight nature compared to traditional steel reinforcement, which tends to corrode and is heavier. FRP has a linear elastic behavior until failure without yielding, while steel reinforcement displays ductile behavior with a distinct yield point and strain hardening. Despite FRP's superior strength-to-weight ratio and non-corrosive properties, steel offers higher modulus of elasticity and ductility, essential for energy dissipation and structural safety under dynamic loads.

Durability and Corrosion Resistance

Fiber Reinforced Polymer (FRP) reinforcement exhibits superior durability compared to steel due to its inherent resistance to corrosion, which is a common issue in steel-reinforced concrete exposed to moisture and chlorides. FRP materials, typically made from glass, carbon, or aramid fibers embedded in a polymer matrix, do not rust or degrade when subjected to harsh environmental conditions, significantly extending the lifespan of reinforced structures. In contrast, steel reinforcement requires protective coatings or treatments to mitigate corrosion, leading to increased maintenance costs and potential structural failures over time.

Installation Practices and Constructability

Fiber Reinforced Polymer (FRP) reinforcement offers significant advantages in installation practices due to its lightweight nature, reducing handling time and labor costs compared to traditional steel reinforcement. FRP's corrosion resistance eliminates the need for extra protective coatings and simplifies on-site storage and transport, enhancing constructability in harsh environments. Steel reinforcement, while structurally robust, demands more intensive handling, cutting, and bending, increasing installation complexity and time in comparison to FRP systems.

Cost Analysis: Initial and Lifecycle Perspectives

FRP (Fiber Reinforced Polymer) reinforcement generally entails higher initial costs compared to traditional steel due to raw material expenses and specialized installation techniques. Lifecycle cost analysis reveals FRP's advantages in corrosion resistance, resulting in reduced maintenance and repair expenditures, especially in aggressive environments. Over extended periods, FRP's durability and lightweight properties can lead to lower total ownership costs despite the upfront investment.

Sustainability and Environmental Impact

Fiber Reinforced Polymer (FRP) reinforcement offers significant sustainability advantages over traditional steel due to its corrosion resistance, which extends the lifespan of structures and reduces the need for repairs and replacements. FRP's lightweight nature decreases transportation emissions and energy consumption during installation, contributing to lower overall environmental impact. Unlike steel, FRP production emits fewer greenhouse gases and avoids issues with resource-intensive mining, positioning it as an eco-friendly alternative in construction projects.

Key Applications: When to Choose FRP or Steel

FRP reinforcement is ideal for corrosive environments such as marine structures, chemical plants, and bridges where durability against rust and chemical attack is critical, ensuring longer service life. Steel reinforcement is preferred in high-load structural applications like buildings and heavy infrastructure due to its superior tensile strength and well-established construction practices. Choosing FRP or steel depends on factors like environmental exposure, load requirements, and lifecycle cost analysis to optimize performance and maintenance.

Future Trends and Innovations in Reinforcement Technologies

Fiber Reinforced Polymer (FRP) reinforcement is rapidly gaining traction due to its superior corrosion resistance, lightweight nature, and high strength-to-weight ratio compared to traditional steel reinforcement. Future trends emphasize the integration of smart FRP composites embedded with sensors for real-time structural health monitoring and self-healing capabilities to extend service life. Innovations also focus on hybrid reinforcement systems combining FRP and steel to optimize performance, cost, and sustainability in advanced civil engineering applications.

Corrosion resistance

Fiber Reinforced Polymer (FRP) offers superior corrosion resistance compared to steel reinforcement, making it ideal for structures exposed to harsh environmental conditions.

Tensile strength

Fiber Reinforced Polymer (FRP) reinforcement offers tensile strengths ranging from 600 to 1500 MPa, significantly surpassing conventional steel reinforcement, which typically provides tensile strengths around 400 to 600 MPa.

Bond behavior

Fiber Reinforced Polymer (FRP) reinforcement exhibits distinct bond behavior compared to steel reinforcement, characterized by lower modulus of elasticity, anisotropic surface properties, and susceptibility to differences in bond strength and slip due to its composite structure and surface texture.

Long-term durability

Fiber Reinforced Polymer (FRP) reinforcement offers superior long-term durability compared to steel reinforcement due to its resistance to corrosion, chemical attack, and fatigue in harsh environments.

Modulus of elasticity

FRP reinforcement typically has a modulus of elasticity ranging from 40 to 60 GPa, which is significantly lower than steel reinforcement's modulus of approximately 200 GPa, affecting stiffness and deflection behavior in structural applications.

Alkali resistance

Fiber Reinforced Polymer (FRP) exhibits superior alkali resistance compared to steel reinforcement, preventing corrosion and enhancing structural durability in concrete environments.

Creep rupture

Fiber Reinforced Polymer (FRP) exhibits superior resistance to creep rupture compared to steel reinforcement, making it more durable under sustained tensile loads in structural applications.

Flexural capacity

Fiber Reinforced Polymer (FRP) reinforcement offers higher corrosion resistance and superior strength-to-weight ratio compared to steel reinforcement, resulting in comparable or enhanced flexural capacity in concrete structures, especially in corrosive environments.

Anisotropy

Fiber Reinforced Polymer (FRP) exhibits pronounced anisotropy with high strength along fiber directions and reduced strength perpendicular to fibers, unlike the isotropic behavior of steel reinforcement which provides uniform strength in all directions.

Fatigue performance

Fiber Reinforced Polymer (FRP) exhibits superior fatigue resistance compared to steel reinforcement due to its corrosion immunity, higher fatigue endurance limit, and stable mechanical properties under cyclic loading.

FRP (Fiber Reinforced Polymer) vs Steel reinforcement Infographic

njnir.com

njnir.com