Mass timber offers a sustainable alternative to steel structures, providing enhanced carbon sequestration and renewable material benefits. Its lightweight nature reduces foundation requirements and accelerates construction timelines compared to steel. Fire resistance and acoustic performance improvements make mass timber increasingly competitive in modern civil engineering projects.

Table of Comparison

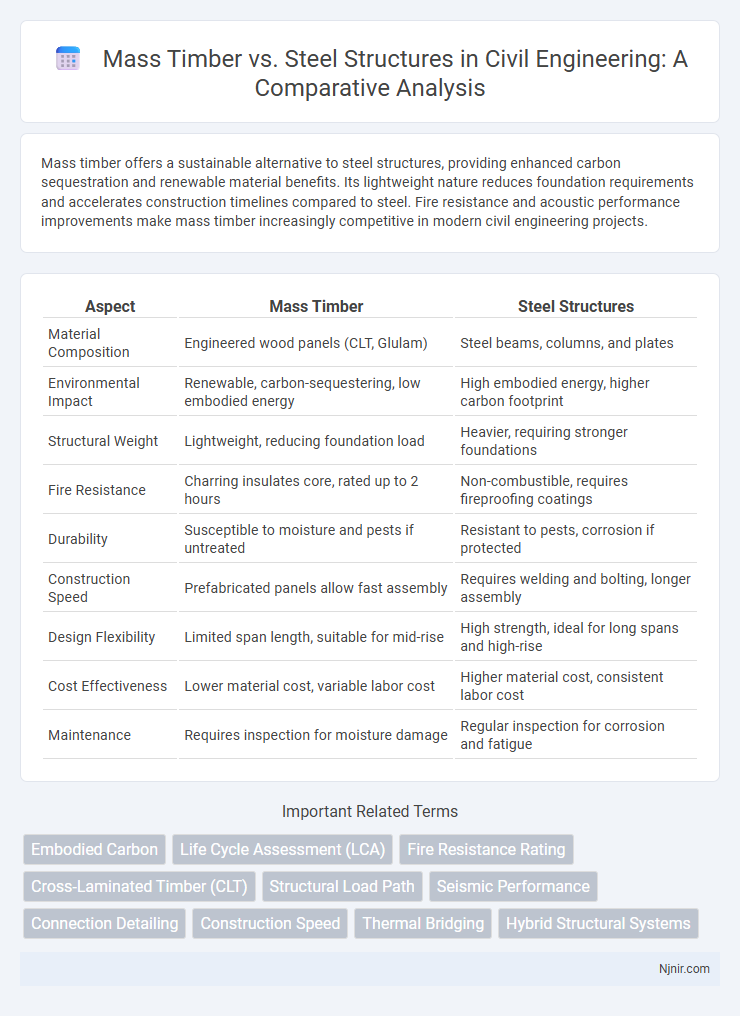

| Aspect | Mass Timber | Steel Structures |

|---|---|---|

| Material Composition | Engineered wood panels (CLT, Glulam) | Steel beams, columns, and plates |

| Environmental Impact | Renewable, carbon-sequestering, low embodied energy | High embodied energy, higher carbon footprint |

| Structural Weight | Lightweight, reducing foundation load | Heavier, requiring stronger foundations |

| Fire Resistance | Charring insulates core, rated up to 2 hours | Non-combustible, requires fireproofing coatings |

| Durability | Susceptible to moisture and pests if untreated | Resistant to pests, corrosion if protected |

| Construction Speed | Prefabricated panels allow fast assembly | Requires welding and bolting, longer assembly |

| Design Flexibility | Limited span length, suitable for mid-rise | High strength, ideal for long spans and high-rise |

| Cost Effectiveness | Lower material cost, variable labor cost | Higher material cost, consistent labor cost |

| Maintenance | Requires inspection for moisture damage | Regular inspection for corrosion and fatigue |

Introduction to Mass Timber and Steel Structures

Mass timber structures utilize engineered wood products such as cross-laminated timber (CLT) and glulam beams, offering sustainable, lightweight, and fast-to-assemble building solutions with excellent thermal performance. Steel structures, composed primarily of fabricated steel sections like I-beams and hollow structural sections, provide superior strength, flexibility, and durability, making them ideal for high-rise buildings and industrial applications. Both materials play crucial roles in modern construction, balancing environmental impact, cost-efficiency, and structural requirements.

Material Properties and Performance

Mass timber offers exceptional sustainability with a high strength-to-weight ratio and excellent thermal insulation properties, making it an energy-efficient choice for modern construction. Steel structures provide superior tensile strength, durability, and resistance to environmental stresses, ensuring long spans and flexible architectural designs. While mass timber excels in fire resistance through charring and carbon sequestration benefits, steel requires protective coatings to prevent corrosion and maintain structural integrity under extreme temperatures.

Sustainability and Environmental Impact

Mass timber structures significantly reduce carbon footprints by sequestering atmospheric CO2 during tree growth and requiring less energy-intensive manufacturing compared to steel production, which emits high levels of greenhouse gases from mining and smelting processes. The renewable nature of timber, especially when sourced from sustainably managed forests, offers a lower environmental impact through biodegradability and reduced waste generation, whereas steel's recyclability demands substantial energy input and contributes to resource depletion. Lifecycle assessments consistently show mass timber's superior performance in lowering embodied carbon and promoting sustainable building practices relative to steel, positioning it as a pivotal material in eco-friendly construction solutions.

Cost Comparison and Economic Factors

Mass timber structures typically offer lower initial material and labor costs compared to steel due to prefabrication efficiencies and reduced foundation requirements. Steel structures, while often more expensive upfront, provide greater durability and potential savings on long-term maintenance and modifications. Economic factors such as location, labor market, and project scale heavily influence which material results in overall cost-effectiveness for construction projects.

Structural Strength and Load-Bearing Capacity

Mass timber offers exceptional strength-to-weight ratios, enabling efficient load distribution through engineered wood products like cross-laminated timber (CLT). Steel structures provide superior tensile strength and higher load-bearing capacity, making them ideal for skyscrapers and heavy industrial applications. Both materials ensure robust structural integrity, but steel excels in resisting dynamic loads while mass timber contributes sustainability and seismic flexibility.

Fire Resistance and Safety Considerations

Mass timber exhibits inherent fire resistance due to its charring behavior, where the outer layer carbonizes and insulates the inner core, maintaining structural integrity longer under fire exposure compared to unprotected steel, which can lose strength rapidly at high temperatures. Fire safety in mass timber construction is enhanced by encapsulation techniques using fire-resistant gypsum boards and sprinkler systems, whereas steel structures require fireproof coatings or cladding to prevent thermal failure. Building codes increasingly recognize engineered wood products like cross-laminated timber (CLT) for their fire performance, promoting safer design choices in sustainable construction.

Construction Speed and Methods

Mass timber construction significantly reduces build time due to prefabricated panels and components that allow rapid on-site assembly, often cutting project schedules by 20-30% compared to steel. Steel structures require complex welding, bolting, and heavy lifting, which can extend construction duration despite their strength and durability. Efficient mass timber methods enhance sustainability and reduce labor costs, making them ideal for faster project delivery without sacrificing structural integrity.

Design Flexibility and Aesthetics

Mass timber structures offer superior design flexibility through customizable panel shapes and natural wood grain patterns that enhance aesthetic warmth and visual appeal. Steel structures provide unparalleled strength and slender profiles, enabling expansive spans and sleek, modern architectural forms. Combining mass timber with steel elements optimizes both structural performance and design sophistication in contemporary construction.

Maintenance and Durability

Mass timber structures offer natural resistance to corrosion and require less frequent maintenance compared to steel, which is prone to rust and often needs protective coatings and inspections. Steel structures provide superior strength and fire resistance but demand regular upkeep to prevent deterioration caused by moisture and environmental exposure. Both materials can achieve long-term durability when properly maintained, but mass timber's organic composition benefits from fewer chemical treatments, reducing lifecycle maintenance costs.

Future Trends in Building with Mass Timber and Steel

Emerging trends indicate a significant shift towards hybrid construction combining mass timber and steel to leverage timber's sustainability and steel's strength for high-rise buildings. Advances in prefabrication and digital design optimize the integration of mass timber panels with steel frameworks, reducing construction time and carbon footprints. Growing regulatory support and innovations in fire resistance and durability enhance mass timber's competitiveness against traditional steel structures in future urban development.

Embodied Carbon

Mass timber structures significantly reduce embodied carbon by storing carbon within wood fibers, whereas steel structures generate higher embodied carbon due to energy-intensive production and carbon emissions.

Life Cycle Assessment (LCA)

Mass timber structures demonstrate lower carbon footprints and reduced embodied energy compared to steel structures according to Life Cycle Assessment (LCA) studies.

Fire Resistance Rating

Mass timber structures can achieve fire resistance ratings of up to 2 hours by charring on the surface, whereas steel structures require additional fireproofing materials to maintain structural integrity under high temperatures.

Cross-Laminated Timber (CLT)

Cross-Laminated Timber (CLT) offers sustainable, lightweight, and high-strength alternatives to steel structures, significantly reducing carbon emissions and construction time in modern building projects.

Structural Load Path

Mass timber structures efficiently distribute structural load through interconnected wood elements with high strength-to-weight ratios, while steel structures utilize rigid steel frames and beams to transfer loads with superior tensile capacity and ductility.

Seismic Performance

Mass timber structures demonstrate superior seismic performance due to their lightweight, high strength-to-weight ratio, and inherent damping properties compared to traditional steel structures.

Connection Detailing

Mass timber connection detailing emphasizes precision-fit joinery and concealed fasteners for aesthetic and structural integrity, while steel structures rely on bolted or welded connections offering high tensile strength and ease of assembly.

Construction Speed

Mass timber structures typically offer faster construction speed than steel due to prefabrication efficiency and lighter components enabling quicker assembly on site.

Thermal Bridging

Mass timber structures significantly reduce thermal bridging compared to steel structures due to wood's lower thermal conductivity and continuous insulation capabilities.

Hybrid Structural Systems

Hybrid structural systems that combine mass timber and steel optimize strength, sustainability, and design flexibility for modern construction projects.

Mass Timber vs Steel Structures Infographic

njnir.com

njnir.com