Smart sensors in civil engineering provide real-time data monitoring and enhanced accuracy compared to traditional instrumentation, enabling proactive maintenance and improved structural health assessment. Unlike conventional tools that require manual data collection and interpretation, smart sensors offer automated data processing and remote accessibility, reducing human error and operational costs. The integration of IoT technology with smart sensors facilitates continuous monitoring of infrastructure, ensuring timely detection of potential issues and extending the lifespan of civil structures.

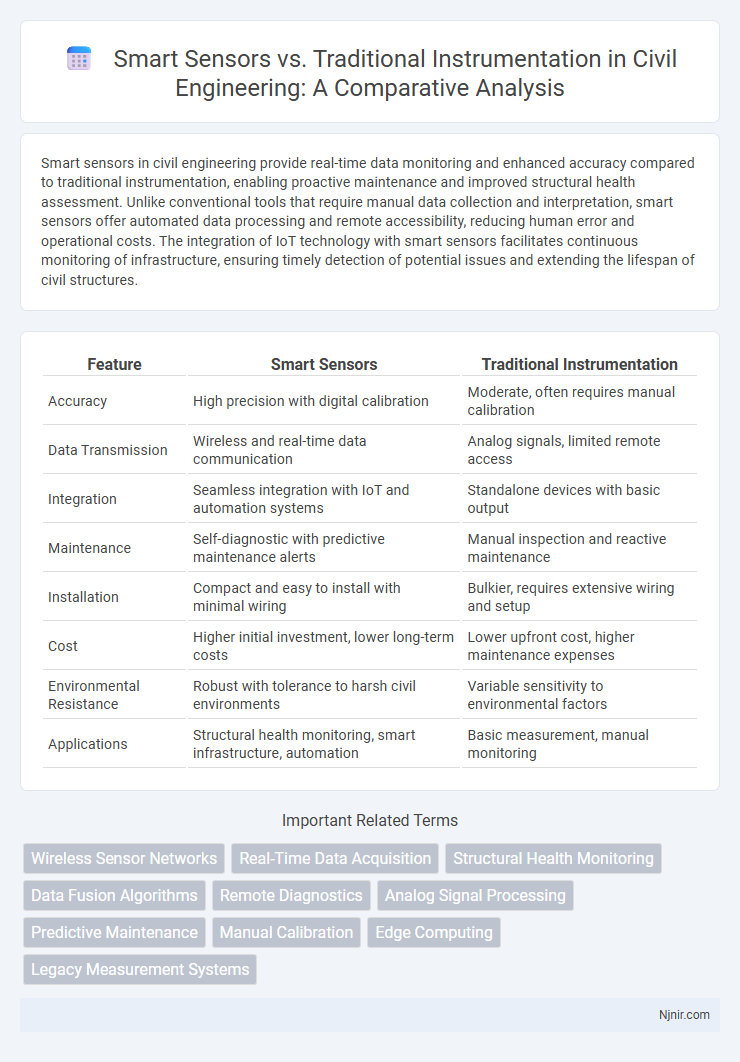

Table of Comparison

| Feature | Smart Sensors | Traditional Instrumentation |

|---|---|---|

| Accuracy | High precision with digital calibration | Moderate, often requires manual calibration |

| Data Transmission | Wireless and real-time data communication | Analog signals, limited remote access |

| Integration | Seamless integration with IoT and automation systems | Standalone devices with basic output |

| Maintenance | Self-diagnostic with predictive maintenance alerts | Manual inspection and reactive maintenance |

| Installation | Compact and easy to install with minimal wiring | Bulkier, requires extensive wiring and setup |

| Cost | Higher initial investment, lower long-term costs | Lower upfront cost, higher maintenance expenses |

| Environmental Resistance | Robust with tolerance to harsh civil environments | Variable sensitivity to environmental factors |

| Applications | Structural health monitoring, smart infrastructure, automation | Basic measurement, manual monitoring |

Introduction to Instrumentation in Civil Engineering

Instrumentation in civil engineering has evolved from traditional mechanical and analog devices to advanced smart sensors equipped with digital communication and real-time data processing capabilities. Smart sensors offer higher accuracy, remote monitoring, and predictive maintenance, enabling improved structural health assessment and construction management. These innovations enhance project safety, efficiency, and lifespan compared to conventional instrumentation methods.

Overview of Smart Sensors

Smart sensors integrate sensing elements with microprocessors, enabling real-time data processing and enhanced accuracy compared to traditional instrumentation. These devices offer self-calibration, diagnostics, and communication capabilities through IoT protocols, improving system efficiency and predictive maintenance. Smart sensors reduce wiring complexity and provide seamless integration in automated and industrial applications, driving advancements in Industry 4.0.

Characteristics of Traditional Instrumentation

Traditional instrumentation relies on analog sensors and discrete devices that require manual calibration and wiring, leading to higher maintenance and installation costs. These systems often lack real-time data processing capabilities and are prone to signal degradation over long distances. Their architecture typically involves limited connectivity and slower response times, restricting scalability and integration with modern automation technologies.

Data Accuracy and Real-Time Monitoring

Smart sensors offer superior data accuracy by integrating advanced signal processing and calibration capabilities directly within the device, reducing human error and environmental interference common in traditional instrumentation. Real-time monitoring is enhanced through wireless connectivity and instant data transmission, enabling continuous observation and rapid response to changes without manual intervention. Traditional instrumentation often relies on periodic sampling and manual readings, leading to delayed data updates and potential inaccuracies in dynamic environments.

Installation and Maintenance Requirements

Smart sensors offer simplified installation with plug-and-play capabilities and wireless connectivity, significantly reducing setup time and labor costs compared to traditional instrumentation that often requires complex wiring and calibration. Maintenance of smart sensors is streamlined through remote diagnostics and self-calibration features, minimizing downtime and the need for manual intervention. Traditional instruments demand regular physical inspections and recalibrations, increasing maintenance frequency and operational expenses.

Cost Implications and Budget Considerations

Smart sensors generally offer lower lifecycle costs compared to traditional instrumentation due to reduced maintenance, enhanced accuracy, and remote monitoring capabilities that minimize downtime and labor expenses. Initial investment in smart sensors can be higher, but budget considerations favor their integration as they enable predictive maintenance and energy savings, ultimately reducing operational expenditures. Traditional instruments may require more frequent calibration and manual intervention, leading to increased ongoing costs and potential budget overruns in the long term.

Integration with Digital Technologies

Smart sensors offer seamless integration with digital technologies through built-in microprocessors and wireless connectivity, enabling real-time data acquisition, processing, and communication. Traditional instrumentation relies on analog signals and manual calibration, limiting compatibility with modern IoT frameworks and digital analytics platforms. This digital integration in smart sensors enhances predictive maintenance, remote monitoring, and automated control systems in industrial applications.

Application Scenarios: When to Use Each Approach

Smart sensors excel in dynamic environments requiring real-time data processing, remote monitoring, and predictive maintenance, such as industrial automation, smart agriculture, and healthcare monitoring. Traditional instrumentation remains ideal for straightforward, cost-sensitive applications with minimal data processing needs, including basic temperature measurement, pressure monitoring, and simple flow control. Selecting the right approach depends on factors like environmental complexity, data integration requirements, and long-term scalability.

Challenges and Limitations

Smart sensors face challenges such as higher initial costs, complexity in integration with existing systems, and reliance on advanced communication protocols, which can limit compatibility. Traditional instrumentation struggles with lower data accuracy, delayed response times, and difficulty in real-time monitoring and remote access. Maintenance of smart sensors often requires specialized skills, while traditional devices may suffer from mechanical wear and limited scalability.

Future Trends in Civil Engineering Instrumentation

Smart sensors integrate advanced data processing, wireless communication, and IoT connectivity, enabling real-time monitoring and predictive maintenance in civil engineering structures. Future trends emphasize the increased use of AI-driven analytics, enhanced sensor fusion techniques, and energy-harvesting capabilities to improve the accuracy, efficiency, and sustainability of infrastructure monitoring systems. These advancements are set to revolutionize traditional instrumentation by providing continuous, adaptive, and autonomous data collection for improved structural health management.

Wireless Sensor Networks

Wireless sensor networks in smart sensors offer real-time data transmission, scalability, and enhanced monitoring capabilities compared to traditional wired instrumentation systems.

Real-Time Data Acquisition

Smart sensors provide real-time data acquisition with higher accuracy and instant processing compared to traditional instrumentation, enabling faster decision-making and enhanced system responsiveness.

Structural Health Monitoring

Smart sensors provide real-time, high-precision data with wireless capabilities for Structural Health Monitoring, surpassing traditional instrumentation's limited responsiveness and manual data collection.

Data Fusion Algorithms

Smart sensors utilize advanced data fusion algorithms to integrate multiple data sources for enhanced accuracy and real-time decision-making, outperforming traditional instrumentation limited by single-sensor data processing.

Remote Diagnostics

Smart sensors enable remote diagnostics through real-time data transmission and advanced analytics, significantly improving maintenance efficiency compared to traditional instrumentation.

Analog Signal Processing

Smart sensors integrate advanced analog signal processing with digital conversion for enhanced accuracy and flexibility, whereas traditional instrumentation relies primarily on raw analog signals with limited processing capabilities.

Predictive Maintenance

Smart sensors enhance predictive maintenance by providing real-time data and advanced analytics, enabling early fault detection and reducing downtime compared to traditional instrumentation.

Manual Calibration

Smart sensors reduce the need for manual calibration by incorporating self-calibration features, unlike traditional instrumentation that relies heavily on frequent manual adjustments to maintain accuracy.

Edge Computing

Smart sensors with integrated edge computing process data locally for faster, real-time decision-making, unlike traditional instrumentation that relies on centralized systems and slower data transmission.

Legacy Measurement Systems

Legacy measurement systems in traditional instrumentation often lack the real-time data accuracy, integration capabilities, and remote monitoring features provided by smart sensors, limiting efficiency and diagnostic potential in industrial applications.

Smart Sensors vs Traditional Instrumentation Infographic

njnir.com

njnir.com