Digital twins offer dynamic, real-time data integration to mirror the actual conditions of civil engineering structures, enabling precise monitoring and predictive maintenance. Building simulation provides static, model-based analysis focusing on performance under predefined scenarios, useful in design optimization and energy efficiency assessment. Combining digital twins with building simulation enhances infrastructure management by merging accurate real-world feedback with advanced predictive modeling.

Table of Comparison

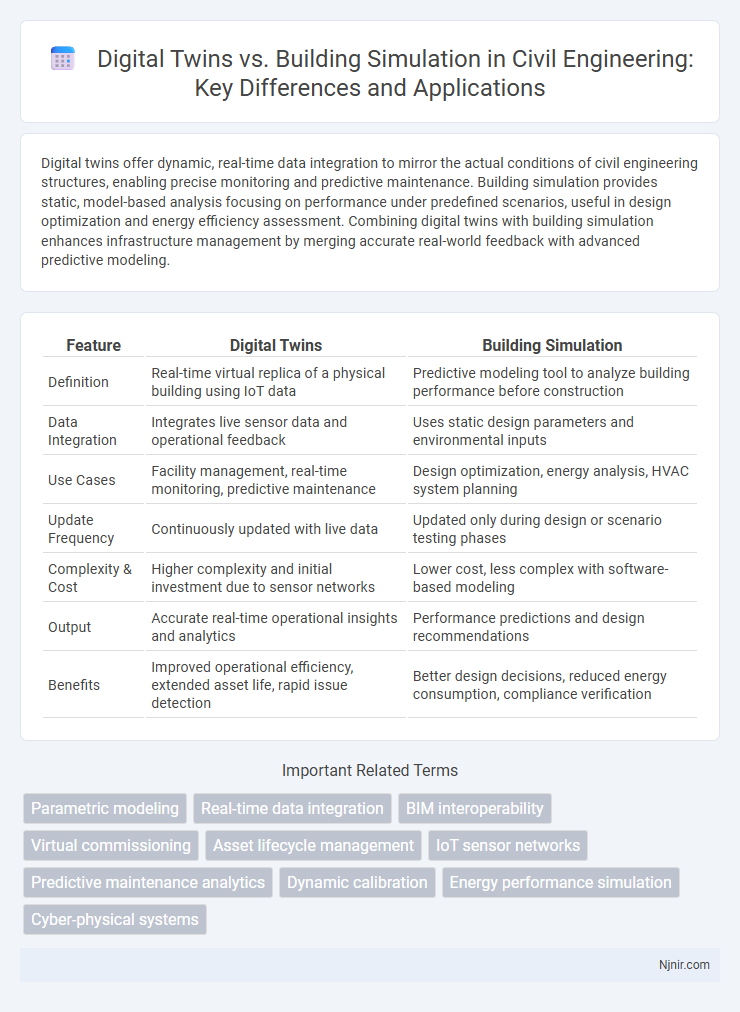

| Feature | Digital Twins | Building Simulation |

|---|---|---|

| Definition | Real-time virtual replica of a physical building using IoT data | Predictive modeling tool to analyze building performance before construction |

| Data Integration | Integrates live sensor data and operational feedback | Uses static design parameters and environmental inputs |

| Use Cases | Facility management, real-time monitoring, predictive maintenance | Design optimization, energy analysis, HVAC system planning |

| Update Frequency | Continuously updated with live data | Updated only during design or scenario testing phases |

| Complexity & Cost | Higher complexity and initial investment due to sensor networks | Lower cost, less complex with software-based modeling |

| Output | Accurate real-time operational insights and analytics | Performance predictions and design recommendations |

| Benefits | Improved operational efficiency, extended asset life, rapid issue detection | Better design decisions, reduced energy consumption, compliance verification |

Introduction to Digital Twins and Building Simulation

Digital twins are dynamic, real-time digital replicas of physical buildings that integrate IoT data to monitor, analyze, and optimize operational performance. Building simulation involves creating detailed virtual models using software to predict energy use, thermal comfort, and environmental impacts during the design phase. While digital twins enable continuous, data-driven facility management, building simulation primarily supports decision-making before construction or retrofitting.

Core Differences Between Digital Twins and Building Simulation

Digital twins provide dynamic, real-time data integration and continuous monitoring of physical assets, enabling predictive analytics and operational decision-making. Building simulation primarily involves static, model-based analysis used during design phases to evaluate performance under various scenarios without live data feedback. The core difference lies in digital twins' real-time interaction and lifecycle management versus building simulation's predictive, pre-construction assessment.

Key Applications in Civil Engineering

Digital twins revolutionize civil engineering by providing real-time monitoring and predictive maintenance for infrastructure, enabling enhanced asset management and optimized performance. Building simulation primarily supports design phase analysis, focusing on energy efficiency, thermal comfort, and daylighting to improve sustainability and occupant experience. Integrating digital twins with building simulation tools offers a comprehensive approach for lifecycle management, reducing costs and increasing resilience in construction projects.

Real-Time Data Integration: Digital Twins Advantage

Digital twins leverage real-time data integration by continuously collecting and analyzing sensor inputs, enabling dynamic and precise monitoring of building performance. Unlike traditional building simulations, which rely on static models and predefined scenarios, digital twins provide up-to-date, actionable insights that reflect current operational conditions. This real-time data capability enhances predictive maintenance, energy optimization, and occupant comfort management in complex built environments.

Simulation Accuracy and Limitations

Digital twins provide higher simulation accuracy by integrating real-time sensor data with detailed building models, enabling dynamic updates and precise predictions of building performance. Building simulations often rely on static or pre-defined parameters, limiting their capacity to reflect real-world changes and leading to potential discrepancies in energy use and occupancy behavior forecasts. The primary limitation of digital twins lies in their dependence on continuous data input and advanced analytics, which can be resource-intensive, while traditional simulations face challenges related to outdated assumptions and reduced adaptability.

Lifecycle Management and Predictive Maintenance

Digital twins enable real-time lifecycle management by integrating sensor data with building models, allowing continuous monitoring and precise prediction of asset performance and maintenance needs. Building simulation primarily offers static, design-phase analysis, limiting its effectiveness in ongoing operations and predictive maintenance. Leveraging digital twins enhances operational efficiency, reduces downtime, and extends asset lifespan through proactive maintenance informed by dynamic, data-driven insights.

Cost and Resource Implications

Digital twins offer real-time data integration and continuous monitoring, significantly reducing operational costs and resource waste compared to traditional building simulations that often rely on static models and periodic updates. While building simulations require extensive upfront investment in modeling and scenario analysis, digital twins enable dynamic adjustments, lowering long-term maintenance expenses and optimizing resource allocation. The scalability of digital twins allows for detailed performance tracking, minimizing energy consumption and material costs over a building's lifecycle.

Interoperability with BIM and Other Technologies

Digital twins enhance interoperability with BIM and other technologies by providing real-time data integration and continuous updates, enabling more accurate and dynamic building management. Building simulation relies on static, pre-defined models that often require manual updates, limiting seamless data exchange and responsiveness. The digital twin's ability to connect with IoT devices, sensors, and cloud platforms ensures comprehensive synchronization across design, construction, and operational phases, driving smarter decision-making.

Future Trends in Civil Engineering Digitization

Future trends in civil engineering digitization emphasize the integration of digital twins over traditional building simulation, offering real-time data synchronization for enhanced decision-making throughout a structure's lifecycle. Advanced digital twins incorporate IoT sensors, AI-driven analytics, and BIM models to provide dynamic, predictive insights that improve asset management, sustainability, and operational efficiency. This shift supports proactive maintenance, continuous performance monitoring, and seamless collaboration among stakeholders, driving innovation in smart infrastructure development.

Choosing the Right Solution for Your Project

Choosing the right solution for your project depends on the level of detail and real-time data integration required; digital twins offer dynamic, real-time monitoring and predictive analytics for operational efficiency, while building simulation focuses on static modeling for design and energy performance analysis. Digital twins are ideal for projects needing continuous performance optimization and IoT connectivity, whereas building simulation suits early-stage design validation and regulatory compliance. Assess project goals, budget, and data availability to determine whether a digital twin's adaptive capabilities or a building simulation's predictive modeling aligns best with your objectives.

Parametric modeling

Digital twins leverage parametric modeling to create dynamic, real-time digital replicas of buildings, enabling continuous optimization, whereas traditional building simulations use static parametric models primarily for design-phase analysis.

Real-time data integration

Digital twins leverage real-time data integration to continuously update building simulations, enabling accurate, dynamic performance monitoring and predictive maintenance.

BIM interoperability

Digital twins enhance building simulation by enabling real-time BIM interoperability, facilitating seamless data integration and dynamic lifecycle management for smarter infrastructure.

Virtual commissioning

Digital twins enable real-time virtual commissioning by integrating live data with building simulations to optimize system performance and reduce commissioning time.

Asset lifecycle management

Digital twins enhance asset lifecycle management by providing real-time data integration and predictive analytics, unlike traditional building simulation which primarily analyzes static design scenarios.

IoT sensor networks

Digital twins leverage IoT sensor networks to provide real-time, dynamic building simulations that enable precise monitoring, predictive maintenance, and enhanced operational efficiency beyond traditional static building simulation models.

Predictive maintenance analytics

Digital twins provide real-time predictive maintenance analytics by integrating sensor data and machine learning algorithms, surpassing traditional building simulations that primarily focus on static performance modeling.

Dynamic calibration

Digital twins leverage dynamic calibration by continuously integrating real-time sensor data for precise, adaptive building simulation, surpassing traditional static modeling methods.

Energy performance simulation

Digital twins provide real-time data integration and dynamic updating for energy performance simulation, enabling more accurate and adaptive building energy management than traditional static building simulation models.

Cyber-physical systems

Digital twins integrate real-time data and cyber-physical systems for dynamic, predictive building simulations that enhance operational efficiency beyond traditional static modeling.

digital twins vs building simulation Infographic

njnir.com

njnir.com