Geopolymer concrete offers enhanced durability and chemical resistance compared to traditional Portland cement concrete, making it ideal for harsh environments. It significantly reduces carbon emissions by utilizing industrial by-products such as fly ash and slag, promoting sustainability in construction. The improved mechanical properties and faster setting times of geopolymer concrete result in increased structural performance and reduced construction time.

Table of Comparison

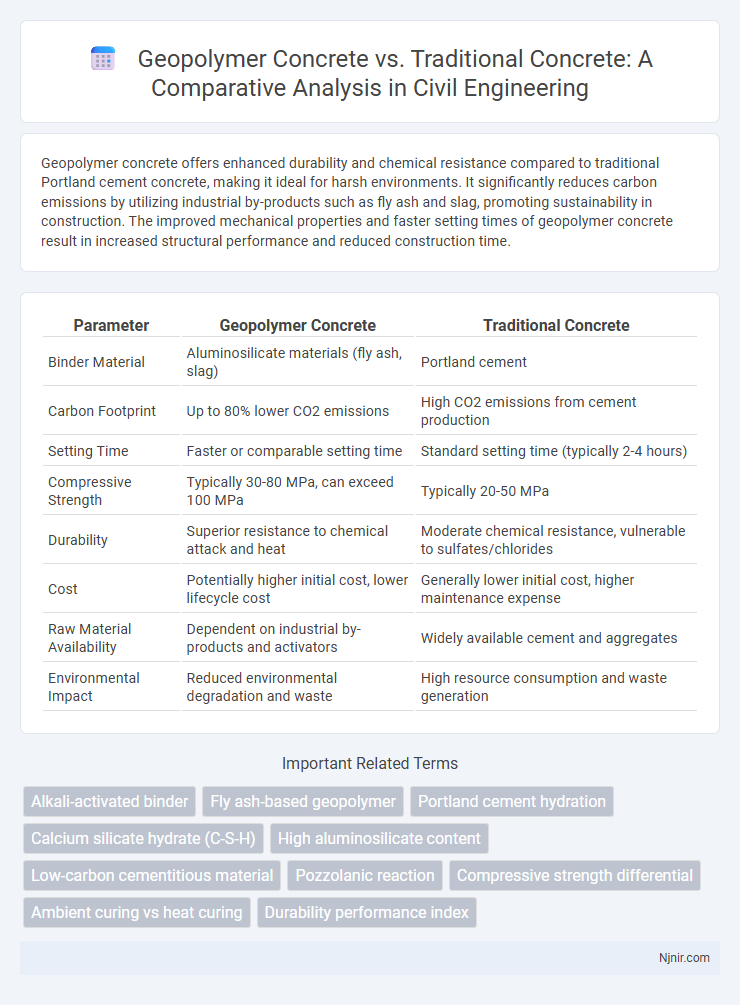

| Parameter | Geopolymer Concrete | Traditional Concrete |

|---|---|---|

| Binder Material | Aluminosilicate materials (fly ash, slag) | Portland cement |

| Carbon Footprint | Up to 80% lower CO2 emissions | High CO2 emissions from cement production |

| Setting Time | Faster or comparable setting time | Standard setting time (typically 2-4 hours) |

| Compressive Strength | Typically 30-80 MPa, can exceed 100 MPa | Typically 20-50 MPa |

| Durability | Superior resistance to chemical attack and heat | Moderate chemical resistance, vulnerable to sulfates/chlorides |

| Cost | Potentially higher initial cost, lower lifecycle cost | Generally lower initial cost, higher maintenance expense |

| Raw Material Availability | Dependent on industrial by-products and activators | Widely available cement and aggregates |

| Environmental Impact | Reduced environmental degradation and waste | High resource consumption and waste generation |

Introduction to Geopolymer and Traditional Concrete

Geopolymer concrete is an innovative material composed of industrial byproducts such as fly ash or slag activated by alkaline solutions, offering superior environmental benefits compared to traditional Portland cement concrete. Traditional concrete relies on cement hydration, which contributes significantly to CO2 emissions worldwide, whereas geopolymer concrete substantially reduces carbon footprint by eliminating the need for cement clinker. This sustainable alternative also exhibits enhanced durability, chemical resistance, and thermal stability, making it a promising option for modern construction.

Composition and Material Sources

Geopolymer concrete utilizes industrial by-products such as fly ash and slag as its primary binder, replacing conventional Portland cement, which is predominantly made from limestone and clay. This eco-friendly composition significantly reduces carbon emissions by minimizing the reliance on cement production, a major source of global CO2 emissions. The alkali-activated aluminosilicate binder in geopolymer concrete offers enhanced durability and chemical resistance compared to the calcium silicate hydrate matrix in traditional concrete.

Manufacturing Process Comparison

Geopolymer concrete manufacturing involves the activation of aluminosilicate materials with alkaline solutions, reducing the need for Portland cement and significantly lowering CO2 emissions. Traditional concrete relies on the hydration of cement clinker produced from limestone and clay at high temperatures, which is energy-intensive and contributes to greenhouse gas emissions. The geopolymer process also offers faster setting times and improved chemical resistance compared to the slower curing and less durable nature of conventional concrete.

Mechanical Properties and Strength

Geopolymer concrete exhibits higher compressive strength and improved resistance to chemical attacks compared to traditional Portland cement concrete, making it ideal for aggressive environments. Its mechanical properties include enhanced tensile strength and superior durability due to reduced microcracking and lower permeability. Studies show geopolymer concrete can achieve compressive strengths exceeding 70 MPa, outperforming conventional concrete in both early and long-term strength development.

Environmental Impact and Sustainability

Geopolymer concrete significantly reduces carbon emissions by utilizing industrial byproducts such as fly ash and slag, cutting CO2 output by up to 80% compared to traditional Portland cement concrete. Its production process consumes less energy and lowers reliance on natural resources, enhancing sustainability in construction projects. The durability and chemical resistance of geopolymer concrete also extend the lifespan of structures, reducing maintenance needs and environmental degradation over time.

Durability and Resistance to Chemicals

Geopolymer concrete exhibits superior durability compared to traditional concrete due to its enhanced resistance to chemical attacks, including acids, sulfates, and chlorides, which commonly degrade ordinary Portland cement. Its dense microstructure and low permeability significantly reduce the ingress of harmful substances, extending the service life of structures in aggressive environments. Studies indicate that geopolymer concrete maintains structural integrity and mechanical strength even under prolonged exposure to harsh chemical conditions, outperforming conventional concrete in industrial and marine applications.

Cost Analysis and Economic Feasibility

Geopolymer concrete offers significant cost savings over traditional concrete by utilizing industrial by-products like fly ash and slag, reducing the reliance on expensive Portland cement. Although initial material costs and specialized production techniques may elevate upfront expenses, the overall lifecycle cost decreases due to improved durability, lower maintenance, and reduced environmental fees. Economic feasibility studies reveal that geopolymer concrete projects can achieve better return on investment in infrastructure applications where sustainability and long-term performance are prioritized.

Construction Applications and Uses

Geopolymer concrete offers enhanced durability and chemical resistance, making it ideal for industrial floors, sewage systems, and marine structures where traditional concrete may deteriorate quickly. Its lower carbon footprint and faster curing times benefit precast elements and large infrastructure projects seeking sustainability and efficiency. Traditional concrete remains preferred for general construction due to its well-established mix designs, cost-effectiveness, and widespread availability in residential and commercial buildings.

Challenges and Limitations

Geopolymer concrete faces challenges such as inconsistent raw material availability, limited long-term performance data, and higher initial costs compared to traditional concrete made from Portland cement. The curing process often requires elevated temperatures, complicating on-site application and increasing energy consumption. Additionally, lack of standardized mix designs and construction codes limits widespread adoption in mainstream infrastructure projects.

Future Trends in Concrete Technology

Geopolymer concrete, leveraging fly ash and slag as sustainable binders, is poised to reduce carbon emissions by up to 80% compared to traditional Portland cement concrete, aligning with global environmental targets. Advances in nanotechnology and additive manufacturing are enhancing the mechanical properties and durability of geopolymer mixtures, promoting their adoption in infrastructure projects. Future trends indicate a growing integration of AI-driven mix design optimization to tailor geopolymer concrete performance for specific applications, surpassing the limitations of conventional concrete technology.

Alkali-activated binder

Alkali-activated binders in geopolymer concrete offer superior chemical resistance, lower carbon footprint, and enhanced durability compared to traditional Portland cement-based concrete.

Fly ash-based geopolymer

Fly ash-based geopolymer concrete offers superior durability, reduced carbon emissions up to 80%, and enhanced chemical resistance compared to traditional Portland cement concrete.

Portland cement hydration

Geopolymer concrete utilizes aluminosilicate materials activated by alkaline solutions, bypassing Portland cement hydration processes that typically produce calcium silicate hydrate (C-S-H) gel in traditional concrete, resulting in lower CO2 emissions and enhanced chemical resistance.

Calcium silicate hydrate (C-S-H)

Geopolymer concrete exhibits enhanced durability and environmental benefits by forming calcium silicate hydrate (C-S-H) gel through alkali activation, differing from traditional concrete's reliance on Portland cement hydration for C-S-H development.

High aluminosilicate content

Geopolymer concrete, characterized by its high aluminosilicate content, offers superior thermal resistance and reduced carbon footprint compared to traditional Portland cement concrete.

Low-carbon cementitious material

Geopolymer concrete, utilizing industrial byproducts like fly ash and slag, offers a low-carbon cementitious alternative to traditional Portland cement concrete by significantly reducing CO2 emissions during production.

Pozzolanic reaction

Geopolymer concrete utilizes a pozzolanic reaction between aluminosilicate materials and alkaline activators to form a dense, durable binder, whereas traditional concrete relies on the hydration of Portland cement for strength development.

Compressive strength differential

Geopolymer concrete typically exhibits a compressive strength that can be 10-30% higher than traditional Portland cement concrete due to its superior chemical bonding and microstructural properties.

Ambient curing vs heat curing

Geopolymer concrete achieves optimal strength through heat curing at 60-90degC, whereas traditional concrete attains ambient curing strength over 28 days at room temperature.

Durability performance index

Geopolymer concrete exhibits a Durability Performance Index up to 30% higher than traditional concrete due to its superior resistance to chemical attacks, sulfate exposure, and elevated temperatures.

geopolymer concrete vs traditional concrete Infographic

njnir.com

njnir.com