Superplasticizers and plasticizers both improve concrete workability but differ significantly in performance and dosage. Superplasticizers provide a higher water reduction, enhancing concrete strength and durability without compromising flowability, making them ideal for high-performance applications. Plasticizers offer moderate water reduction and improved workability, suitable for basic concrete mixes but less effective in achieving high strength or fluidity.

Table of Comparison

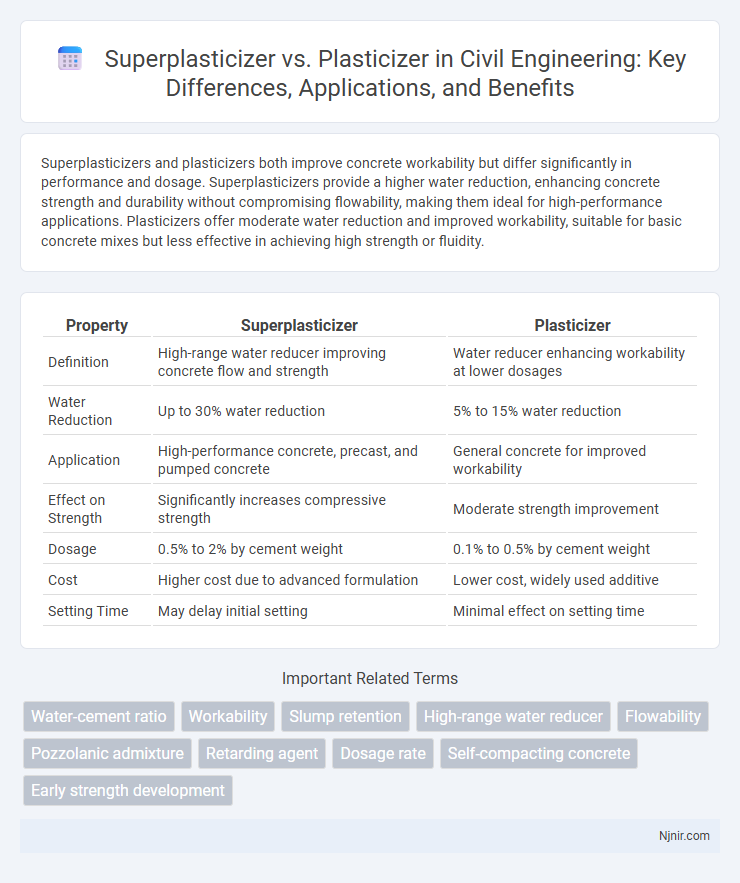

| Property | Superplasticizer | Plasticizer |

|---|---|---|

| Definition | High-range water reducer improving concrete flow and strength | Water reducer enhancing workability at lower dosages |

| Water Reduction | Up to 30% water reduction | 5% to 15% water reduction |

| Application | High-performance concrete, precast, and pumped concrete | General concrete for improved workability |

| Effect on Strength | Significantly increases compressive strength | Moderate strength improvement |

| Dosage | 0.5% to 2% by cement weight | 0.1% to 0.5% by cement weight |

| Cost | Higher cost due to advanced formulation | Lower cost, widely used additive |

| Setting Time | May delay initial setting | Minimal effect on setting time |

Introduction to Admixtures in Concrete

Superplasticizers and plasticizers are essential chemical admixtures used to modify the workability and strength of concrete. Plasticizers primarily reduce water content by about 5-15%, improving workability, while superplasticizers can decrease water content by up to 30%, enabling high-strength and high-performance concrete mixes. These admixtures enhance concrete properties by dispersing cement particles, increasing fluidity without compromising durability or setting time.

Defining Superplasticizers and Plasticizers

Superplasticizers are high-range water reducers used in concrete to significantly increase workability without adding extra water, enhancing strength and durability. Plasticizers, also known as water reducers, improve concrete fluidity by reducing water content but to a lesser extent than superplasticizers. Both admixtures modify the rheology of fresh concrete, with superplasticizers enabling higher performance in advanced construction applications.

Chemical Composition and Mechanism of Action

Superplasticizers are high-range water reducers primarily composed of sulfonated melamine formaldehyde condensates, sulfonated naphthalene formaldehyde condensates, or polycarboxylate ethers, functioning by dispersing cement particles through electrostatic repulsion and steric hindrance. In contrast, plasticizers or water reducers mainly consist of lignosulfonates, hydroxylated carboxylic acids, or low-range melamine-based compounds, acting by reducing the surface tension of water and improving particle wetting to increase workability. The distinct chemical structures dictate their action mechanisms: superplasticizers provide superior dispersion leading to significant water reduction, whereas plasticizers moderately enhance flow by altering mix viscosity.

Effects on Workability and Slump Retention

Superplasticizers significantly enhance concrete workability by reducing water demand while maintaining high slump for extended periods, enabling easier placement and finishing. Plasticizers improve workability by moderately lowering water content but offer limited slump retention, causing faster slump loss over time. The extended slump retention of superplasticizers makes them ideal for complex pours and long transport times compared to plasticizers which suit shorter work cycles.

Impact on Water Reduction and Concrete Strength

Superplasticizers offer significantly higher water reduction, typically 20-30% compared to 5-10% for plasticizers, enhancing concrete fluidity without compromising workability. This increased water reduction directly improves concrete strength, with superplasticizer-treated mixes achieving compressive strengths up to 20-30% higher than those with traditional plasticizers. The advanced molecular structure of superplasticizers disperses cement particles more effectively, resulting in denser microstructure and superior durability.

Dosage Requirements and Compatibility

Superplasticizers require lower dosages, typically around 0.2% to 0.5% by weight of cement, compared to plasticizers which are used at 0.5% to 1.5%. Superplasticizers offer higher water reduction, enhancing workability without compromising strength, but may exhibit limited compatibility with certain cement types. Plasticizers provide moderate water reduction and better compatibility across a wider range of cementitious materials, making dosage adjustment crucial for optimal performance.

Applications in Modern Construction Projects

Superplasticizers significantly improve the workability and strength of concrete, making them essential for high-performance applications such as high-rise buildings, bridges, and precast concrete elements. Plasticizers are commonly used in general construction for reducing water content and improving mix flowability in concrete slabs, pavements, and residential structures. Modern construction projects favor superplasticizers for their ability to produce high-strength concrete with reduced cement content, contributing to sustainability and durability.

Advantages and Limitations of Each Admixture

Superplasticizers significantly enhance concrete workability and strength by reducing water content by up to 30%, offering superior flow without compromising durability, but they may increase initial cost and require precise dosing to avoid segregation. Plasticizers improve concrete fluidity moderately with a 5-15% water reduction, providing cost-effective workability benefits while potentially limiting long-term strength gains and increasing risk of bleeding or shrinkage. Both admixtures optimize concrete performance, with superplasticizers preferred for high-strength and complex casting, whereas plasticizers suit general applications demanding moderate workability enhancement.

Cost-Benefit Analysis in Project Selection

Superplasticizers deliver higher workability and strength enhancement at a comparatively higher upfront cost than plasticizers, making them ideal for high-performance concrete applications where durability and reduced water content are critical. Plasticizers offer moderate improvement in concrete flowability at a lower price point, suitable for standard construction projects with budget constraints. Evaluating the cost-benefit balance depends on project requirements for structural integrity, longevity, and budget allocation, with superplasticizers favored for advanced engineering projects despite their premium cost.

Key Considerations for Engineers in Choosing Between Superplasticizer and Plasticizer

Engineers must evaluate the desired workability and strength of concrete when choosing between superplasticizers and plasticizers, as superplasticizers significantly increase fluidity without additional water, enhancing compressive strength. The setting time and chemical compatibility with cement types are crucial, with superplasticizers often providing better slump retention but potentially altering setting characteristics. Cost-effectiveness and environmental impact also influence selection, where plasticizers may suit simpler applications and superplasticizers are preferred for high-performance concrete requiring superior durability and reduced permeability.

Water-cement ratio

Superplasticizers significantly reduce the water-cement ratio in concrete mixtures compared to plasticizers, enhancing strength and durability by enabling higher workability with less water.

Workability

Superplasticizers significantly enhance concrete workability by reducing water content without compromising strength, whereas plasticizers moderately improve workability with less water reduction.

Slump retention

Superplasticizers provide superior slump retention compared to plasticizers by maintaining workability in concrete for extended periods without increasing water content.

High-range water reducer

Superplasticizers, or high-range water reducers, significantly improve concrete workability by reducing water content up to 30% compared to traditional plasticizers, which typically reduce water content by only 5-15%.

Flowability

Superplasticizers significantly enhance concrete flowability by reducing water content while plasticizers moderately improve workability with less impact on water reduction.

Pozzolanic admixture

Superplasticizers enhance the workability and strength of pozzolanic admixtures by significantly reducing water content compared to plasticizers, resulting in denser and more durable concrete.

Retarding agent

Superplasticizers act as retarding agents by significantly delaying cement hydration and setting time, unlike plasticizers which provide moderate water reduction without substantial retardation effects.

Dosage rate

Superplasticizers typically require a lower dosage rate of 0.2% to 0.5% by weight of cement compared to plasticizers, which are used at 0.3% to 1.5%.

Self-compacting concrete

Superplasticizers significantly improve the flowability and strength of self-compacting concrete by reducing water content without compromising workability, whereas plasticizers moderately enhance workability with less impact on water reduction.

Early strength development

Superplasticizers significantly accelerate early strength development in concrete by enhancing workability and reducing water content, while plasticizers provide moderate improvements primarily through water reduction without drastically impacting early strength.

Superplasticizer vs Plasticizer Infographic

njnir.com

njnir.com