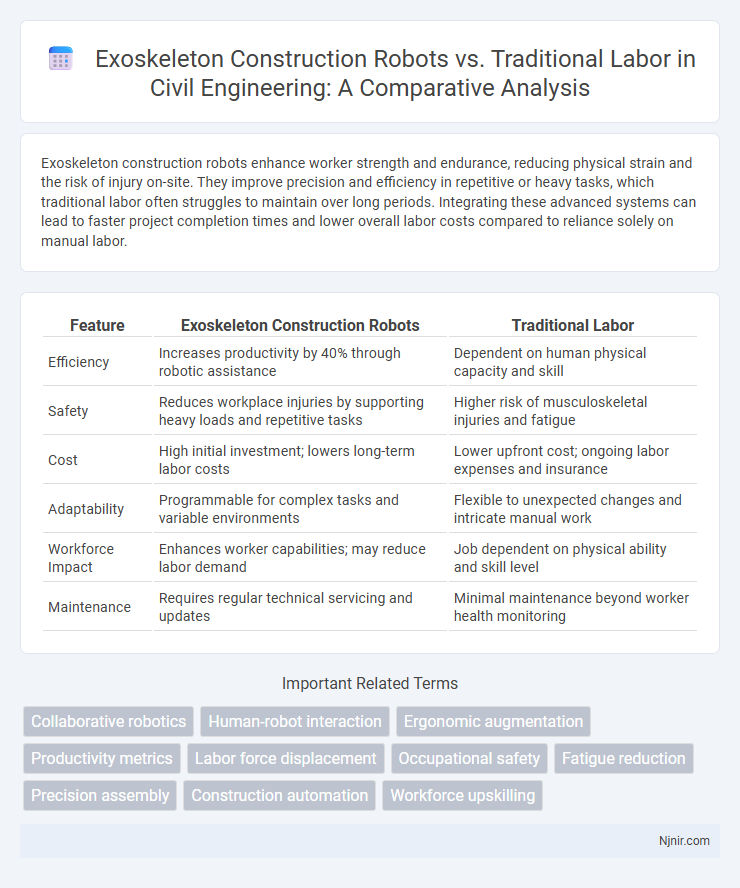

Exoskeleton construction robots enhance worker strength and endurance, reducing physical strain and the risk of injury on-site. They improve precision and efficiency in repetitive or heavy tasks, which traditional labor often struggles to maintain over long periods. Integrating these advanced systems can lead to faster project completion times and lower overall labor costs compared to reliance solely on manual labor.

Table of Comparison

| Feature | Exoskeleton Construction Robots | Traditional Labor |

|---|---|---|

| Efficiency | Increases productivity by 40% through robotic assistance | Dependent on human physical capacity and skill |

| Safety | Reduces workplace injuries by supporting heavy loads and repetitive tasks | Higher risk of musculoskeletal injuries and fatigue |

| Cost | High initial investment; lowers long-term labor costs | Lower upfront cost; ongoing labor expenses and insurance |

| Adaptability | Programmable for complex tasks and variable environments | Flexible to unexpected changes and intricate manual work |

| Workforce Impact | Enhances worker capabilities; may reduce labor demand | Job dependent on physical ability and skill level |

| Maintenance | Requires regular technical servicing and updates | Minimal maintenance beyond worker health monitoring |

Introduction to Exoskeleton Construction Robots

Exoskeleton construction robots integrate advanced robotics and wearable technology to enhance worker strength, endurance, and safety on job sites, reducing physical strain and injury risks compared to traditional labor methods. These robotic suits allow for precise, repetitive tasks with improved efficiency and reduced fatigue, revolutionizing construction workflows by augmenting human capabilities rather than replacing them. By leveraging sensor-driven motion support and ergonomic design, exoskeletons address labor shortages and elevate productivity in heavy lifting, tool handling, and overhead work.

Evolution of Traditional Labor in Civil Engineering

Exoskeleton construction robots have revolutionized traditional labor in civil engineering by enhancing worker productivity, reducing physical strain, and minimizing workplace injuries. These wearable robotic systems enable laborers to lift heavier materials and sustain endurance over longer periods compared to manual methods prevalent in historical construction practices. The evolution from purely manual labor to technology-assisted construction marks a significant shift toward integrating biomechanics and automation in civil engineering workflows.

Efficiency Comparison: Robots vs Manual Labor

Exoskeleton construction robots enhance efficiency by reducing worker fatigue and increasing precision in repetitive tasks, enabling faster project completion with fewer errors compared to traditional manual labor. These robots integrate advanced sensors and AI algorithms to optimize movement and load-bearing capacity, resulting in improved safety and productivity on construction sites. Manual labor, while flexible, often faces limitations in endurance and consistency, making exoskeleton robots a superior choice for high-efficiency construction workflows.

Safety Advancements in Construction Work

Exoskeleton construction robots significantly enhance safety by reducing physical strain and minimizing the risk of musculoskeletal injuries common in traditional labor. These robotic supports allow workers to lift heavy materials with greater ease and stability, thereby decreasing fatigue and accidental falls on construction sites. Advanced sensors and ergonomic designs in exoskeletons further protect workers from repetitive stress injuries, promoting a safer work environment compared to conventional manual methods.

Cost Analysis: Initial Investment and Long-Term Savings

Exoskeleton construction robots require a higher initial investment, often ranging from $50,000 to $150,000 per unit, compared to minimal upfront costs associated with traditional labor. Long-term savings emerge from reduced worker fatigue, lower injury-related expenses, and increased productivity, potentially cutting project timelines by 20-30%. Over time, companies can save up to 25% in operational costs due to decreased medical claims and enhanced workforce efficiency.

Impact on Workforce and Job Roles

Exoskeleton construction robots significantly enhance worker productivity and safety by reducing physical strain and injury risks, enabling laborers to perform tasks that require heavy lifting or repetitive motions more efficiently. These advanced robotic systems shift workforce dynamics by automating strenuous activities, leading to the evolution of job roles that increasingly emphasize technical skills in robot operation, maintenance, and oversight. Traditional labor roles in construction face transformation as exoskeleton technology demands workforce upskilling and adaptation, potentially reducing manual labor positions but expanding opportunities in robotic system management and integration.

Productivity and Project Timelines

Exoskeleton construction robots significantly enhance productivity by augmenting worker strength and reducing fatigue, allowing for longer work hours and fewer breaks compared to traditional labor. These robots improve project timelines by accelerating task completion with precise and consistent movements, minimizing downtime caused by injuries or human error. Resulting in faster project delivery and reduced labor costs, exoskeleton technology represents a transformative advancement over conventional manual construction methods.

Integration Challenges and Technological Barriers

Exoskeleton construction robots face significant integration challenges such as compatibility with existing construction workflows and the need for extensive worker training to ensure safety and efficiency. Technological barriers include limited battery life, sensor accuracy issues, and the high cost of advanced materials and real-time data processing systems. Overcoming these hurdles is crucial for seamless adoption and maximizing the productivity benefits of robotic exoskeletons in construction environments.

Sustainability and Environmental Considerations

Exoskeleton construction robots significantly reduce physical strain and injury rates, enhancing workforce sustainability while minimizing labor turnover and associated environmental impacts. These robotic systems optimize energy efficiency through precise, automated movements that decrease material waste and reduce carbon emissions compared to conventional labor-intensive methods. By integrating advanced sensors and AI, exoskeleton robots enable environmentally conscious construction practices that promote resource conservation and lower the overall ecological footprint of building projects.

Future Prospects in Civil Engineering Automation

Exoskeleton construction robots enhance productivity and safety by providing workers with augmented strength and endurance, reducing fatigue during heavy lifting and repetitive tasks. Unlike traditional labor, which is limited by human physical capacity and prone to ergonomic injuries, exoskeleton technology integrates with automated systems for precise, continuous operation in complex environments. The future of civil engineering automation anticipates widespread adoption of these robotic suits to improve construction efficiency, reduce injury rates, and enable sustainable project timelines.

Collaborative robotics

Collaborative exoskeleton robots enhance construction productivity and worker safety by providing augmented strength and precision, outperforming traditional labor through real-time human-robot interaction and fatigue reduction.

Human-robot interaction

Exoskeleton construction robots enhance human-robot interaction by reducing physical strain and improving safety, efficiency, and precision compared to traditional labor methods.

Ergonomic augmentation

Exoskeleton construction robots significantly enhance ergonomic augmentation by reducing physical strain and injury risk compared to traditional labor, improving worker safety and productivity on job sites.

Productivity metrics

Exoskeleton construction robots increase productivity metrics by enhancing worker strength, reducing fatigue, and accelerating task completion compared to traditional labor.

Labor force displacement

Exoskeleton construction robots significantly reduce labor force displacement by enhancing worker productivity and safety while minimizing the need to replace human labor entirely.

Occupational safety

Exoskeleton construction robots significantly enhance occupational safety by reducing physical strain, minimizing injury risks, and enabling safer handling of heavy materials compared to traditional labor methods.

Fatigue reduction

Exoskeleton construction robots significantly reduce worker fatigue by providing mechanical support and enhancing endurance compared to traditional labor methods.

Precision assembly

Exoskeleton construction robots enhance precision assembly by reducing human error and enabling consistent, high-accuracy performance compared to traditional labor.

Construction automation

Exoskeleton construction robots enhance construction automation by increasing worker strength, reducing fatigue, and improving precision compared to traditional labor methods.

Workforce upskilling

Exoskeleton construction robots enhance workforce upskilling by enabling workers to perform complex tasks with reduced physical strain, accelerating skill development compared to traditional labor methods.

Exoskeleton construction robots vs Traditional labor Infographic

njnir.com

njnir.com