Fly ash concrete offers enhanced workability and improved long-term strength due to the pozzolanic reaction of fly ash with lime, reducing permeability and increasing durability in aggressive environments. Slag cement concrete, derived from ground granulated blast-furnace slag, provides superior resistance to sulfate attack and reduced heat of hydration, making it ideal for mass concrete applications and harsh chemical exposures. Both materials contribute to sustainable construction practices by utilizing industrial byproducts and improving concrete performance compared to traditional Portland cement.

Table of Comparison

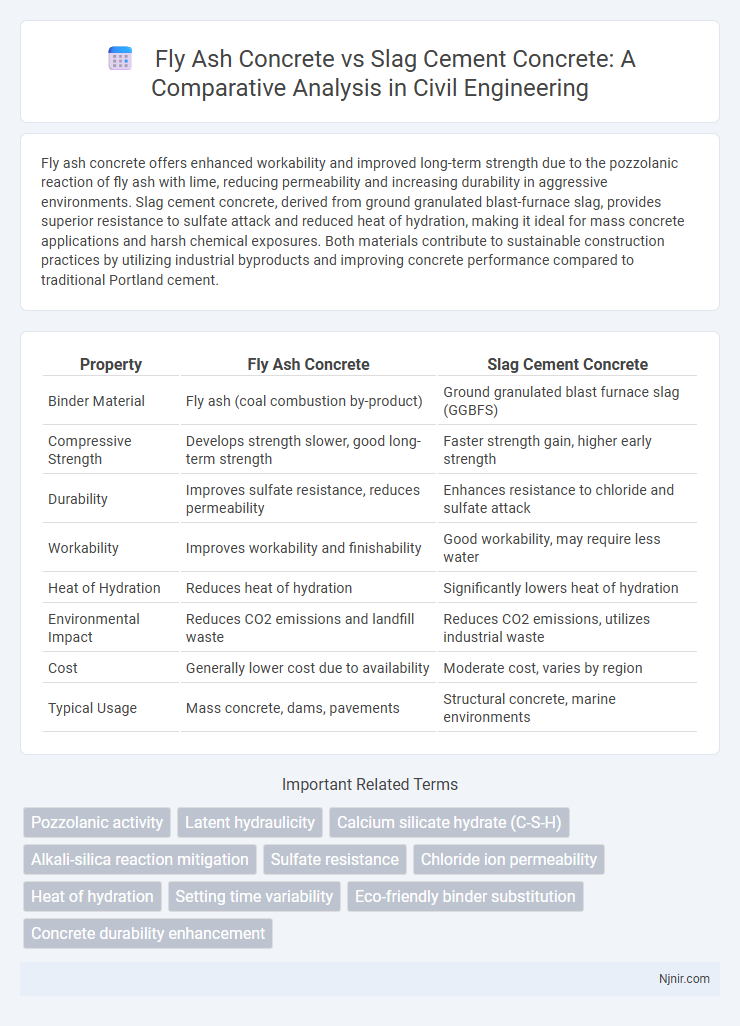

| Property | Fly Ash Concrete | Slag Cement Concrete |

|---|---|---|

| Binder Material | Fly ash (coal combustion by-product) | Ground granulated blast furnace slag (GGBFS) |

| Compressive Strength | Develops strength slower, good long-term strength | Faster strength gain, higher early strength |

| Durability | Improves sulfate resistance, reduces permeability | Enhances resistance to chloride and sulfate attack |

| Workability | Improves workability and finishability | Good workability, may require less water |

| Heat of Hydration | Reduces heat of hydration | Significantly lowers heat of hydration |

| Environmental Impact | Reduces CO2 emissions and landfill waste | Reduces CO2 emissions, utilizes industrial waste |

| Cost | Generally lower cost due to availability | Moderate cost, varies by region |

| Typical Usage | Mass concrete, dams, pavements | Structural concrete, marine environments |

Introduction to Fly Ash and Slag Cement in Concrete

Fly ash concrete incorporates byproducts from coal combustion, enhancing workability and long-term strength while reducing permeability and environmental impact. Slag cement concrete utilizes ground granulated blast-furnace slag, a steel industry byproduct, improving durability and resistance to chemical attack. Both materials contribute to sustainable construction by recycling industrial waste and improving concrete performance.

Chemical Composition and Properties

Fly ash concrete primarily consists of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), contributing to its pozzolanic activity, which enhances long-term strength and durability. Slag cement concrete contains higher calcium oxide (CaO) and magnesium oxide (MgO) levels, resulting in improved sulfate resistance and lower heat of hydration. Both materials improve concrete workability and reduce permeability, but slag cement generally offers faster strength gain and better resistance to chemical attacks.

Production and Sourcing Methods

Fly ash concrete utilizes byproducts from coal combustion in power plants, where fly ash is collected from flue gases using electrostatic precipitators or fabric filters, making it dependent on the availability of coal-fired power generation. Slag cement concrete incorporates ground granulated blast-furnace slag (GGBFS), a byproduct of iron production, sourced by quenching molten slag from blast furnaces and then grinding it into a fine powder. Production of fly ash generally involves less processing compared to slag cement, which requires controlled cooling and grinding, impacting the uniformity and properties of the resulting cementitious material.

Workability and Fresh Concrete Characteristics

Fly ash concrete exhibits improved workability due to the spherical shape and smooth texture of fly ash particles, which reduce water demand and enhance flowability. Slag cement concrete also offers good workability, attributed to the angular shape of slag particles that provide better particle packing but may require slightly more water than fly ash concrete. Fresh concrete characteristics of fly ash concrete include slower setting time and reduced heat of hydration, while slag cement concrete shows moderate setting time with increased early strength development compared to fly ash mixes.

Strength Development and Mechanical Performance

Fly ash concrete exhibits slower early strength development compared to slag cement concrete due to its pozzolanic reaction, which enhances long-term strength and durability. Slag cement concrete achieves higher early strength and improved mechanical performance, including increased compressive and flexural strength, owing to its latent hydraulic properties. Both materials improve concrete durability and reduce permeability, but slag cement concrete is preferred for applications requiring rapid strength gain and enhanced mechanical stability.

Durability and Resistance to Chemical Attack

Fly ash concrete exhibits enhanced durability due to its refined pore structure, resulting in improved resistance to sulfate and alkali-silica attacks compared to ordinary concrete. Slag cement concrete offers superior resistance to chloride-induced corrosion and chemical deterioration, making it ideal for marine and industrial environments. Both materials significantly increase concrete's lifespan by reducing permeability and mitigating damage from aggressive chemical exposures.

Environmental Impact and Sustainability

Fly ash concrete reduces carbon emissions by utilizing waste byproducts from coal combustion, decreasing reliance on Portland cement and lowering overall greenhouse gas output. Slag cement concrete uses ground granulated blast-furnace slag, a steel industry byproduct, which enhances durability and reduces landfill waste while cutting CO2 emissions compared to traditional concrete. Both materials contribute to sustainable construction through improved resource efficiency, waste valorization, and enhanced long-term environmental performance.

Cost Analysis and Project Economics

Fly ash concrete generally offers lower initial material costs compared to slag cement concrete due to the wider availability and lower processing expenses of fly ash as a byproduct of coal combustion. Slag cement concrete, while potentially more expensive upfront, provides enhanced durability and strength, often resulting in reduced maintenance and lifecycle costs that can improve overall project economics. Selecting between the two materials requires balancing immediate budget constraints with long-term financial benefits such as extended service life and reduced repair frequency.

Applications in Construction Projects

Fly ash concrete is widely used in large-scale infrastructure projects such as bridges, dams, and high-rise buildings due to its improved workability, durability, and reduced heat of hydration. Slag cement concrete is preferred in marine structures, sewage systems, and pavement constructions because of its enhanced resistance to sulfate attack and superior long-term strength development. Both materials contribute to sustainable construction by utilizing industrial by-products and reducing cement consumption in various project applications.

Challenges and Limitations in Practical Use

Fly ash concrete often faces challenges such as slower early strength development and variability in fly ash quality, which can affect consistency and long-term performance. Slag cement concrete may encounter limitations related to availability, higher cost, and potential incompatibility with certain admixtures or curing conditions. Both materials require careful mix design adjustments and thorough quality control to mitigate issues like delayed setting times, reduced early-age strength, and potential durability concerns.

Pozzolanic activity

Fly ash concrete exhibits slower pozzolanic activity leading to gradual strength gain, while slag cement concrete shows faster pozzolanic reaction resulting in higher early strength development.

Latent hydraulicity

Fly ash concrete exhibits slower latent hydraulicity compared to slag cement concrete, resulting in extended strength development and enhanced long-term durability.

Calcium silicate hydrate (C-S-H)

Fly ash concrete generates more calcium silicate hydrate (C-S-H) gel over time, enhancing long-term strength and durability compared to slag cement concrete, which produces a denser but slower-forming C-S-H structure.

Alkali-silica reaction mitigation

Fly ash concrete significantly reduces Alkali-silica reaction (ASR) expansion by consuming alkalis and controlling pore solution chemistry, whereas slag cement concrete also mitigates ASR but typically requires higher replacement levels for comparable effectiveness.

Sulfate resistance

Fly ash concrete exhibits higher sulfate resistance than slag cement concrete due to its lower permeability and reduced calcium hydroxide content.

Chloride ion permeability

Fly ash concrete exhibits lower chloride ion permeability than slag cement concrete, enhancing its durability and resistance to chloride-induced corrosion in reinforced structures.

Heat of hydration

Fly ash concrete generates significantly lower heat of hydration compared to slag cement concrete, making it more suitable for mass concrete applications to reduce thermal cracking.

Setting time variability

Fly ash concrete generally exhibits longer and more variable setting times compared to slag cement concrete due to differences in their chemical compositions and hydration rates.

Eco-friendly binder substitution

Fly ash concrete and slag cement concrete both serve as eco-friendly binder substitutions by reducing Portland cement usage, with fly ash improving workability and durability and slag cement enhancing strength and sulfate resistance.

Concrete durability enhancement

Fly ash concrete enhances concrete durability by reducing permeability and improving resistance to sulfate attack, while slag cement concrete significantly increases resistance to chloride ingress and alkali-silica reaction, making both materials effective in extending concrete lifespan under different environmental exposures.

Fly ash concrete vs slag cement concrete Infographic

njnir.com

njnir.com