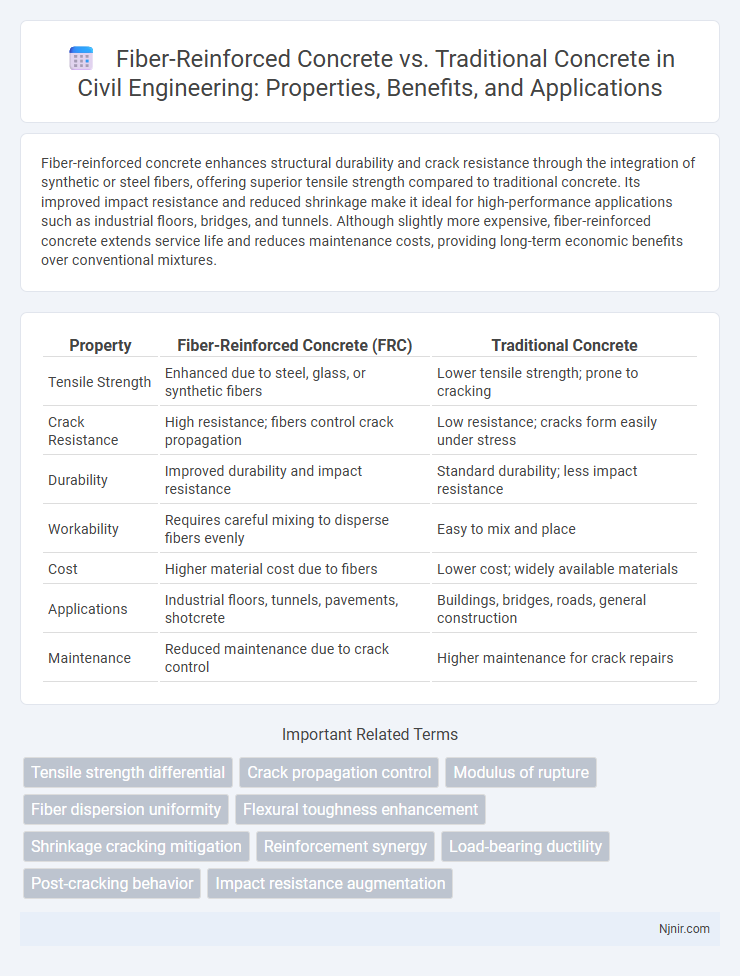

Fiber-reinforced concrete enhances structural durability and crack resistance through the integration of synthetic or steel fibers, offering superior tensile strength compared to traditional concrete. Its improved impact resistance and reduced shrinkage make it ideal for high-performance applications such as industrial floors, bridges, and tunnels. Although slightly more expensive, fiber-reinforced concrete extends service life and reduces maintenance costs, providing long-term economic benefits over conventional mixtures.

Table of Comparison

| Property | Fiber-Reinforced Concrete (FRC) | Traditional Concrete |

|---|---|---|

| Tensile Strength | Enhanced due to steel, glass, or synthetic fibers | Lower tensile strength; prone to cracking |

| Crack Resistance | High resistance; fibers control crack propagation | Low resistance; cracks form easily under stress |

| Durability | Improved durability and impact resistance | Standard durability; less impact resistance |

| Workability | Requires careful mixing to disperse fibers evenly | Easy to mix and place |

| Cost | Higher material cost due to fibers | Lower cost; widely available materials |

| Applications | Industrial floors, tunnels, pavements, shotcrete | Buildings, bridges, roads, general construction |

| Maintenance | Reduced maintenance due to crack control | Higher maintenance for crack repairs |

Introduction to Fiber-Reinforced Concrete and Traditional Concrete

Fiber-reinforced concrete (FRC) incorporates discrete fibers such as steel, glass, synthetic, or natural fibers to enhance tensile strength, crack resistance, and durability compared to traditional concrete, which relies primarily on cement, sand, gravel, and water. Traditional concrete exhibits excellent compressive strength but is prone to cracking and requires reinforcement, typically with steel bars, to manage tensile stresses. The integration of fibers in FRC improves impact resistance, reduces shrinkage cracks, and extends structural lifespan, making it suitable for applications like pavements, tunnels, and precast elements where enhanced performance is critical.

Key Material Composition Differences

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, synthetic, or natural fibers that enhance tensile strength and crack resistance, unlike traditional concrete which primarily relies on cement, water, and aggregate. The addition of fibers improves ductility and impact resistance without significantly altering the traditional concrete's compressive strength. This composite modification in material composition results in superior durability and reduced shrinkage cracking compared to conventional concrete mixes.

Mechanical Properties and Strength Comparison

Fiber-reinforced concrete exhibits significantly enhanced mechanical properties compared to traditional concrete, including increased tensile strength, improved flexural toughness, and higher resistance to cracking and impact loads. The incorporation of fibers, such as steel, glass, or synthetic materials, improves post-cracking behavior and ductility, resulting in superior durability and structural integrity under dynamic and static loads. Traditional concrete often demonstrates higher compressive strength but is more brittle and prone to sudden failure, whereas fiber-reinforced concrete offers balanced strength and toughness, making it ideal for applications requiring enhanced durability and load-bearing capacity.

Crack Resistance and Durability Analysis

Fiber-reinforced concrete significantly enhances crack resistance by distributing stresses through embedded fibers, reducing microcrack formation and propagation compared to traditional concrete. Its durability surpasses that of conventional mixes, exhibiting improved performance against freeze-thaw cycles, impact loads, and chemical attacks due to the synergistic effect of fibers and matrix bonding. Studies show that incorporating steel, synthetic, or glass fibers increases tensile strength and toughness, prolonging service life and minimizing maintenance in infrastructure applications.

Workability and Construction Techniques

Fiber-reinforced concrete enhances workability by improving mix cohesion and reducing segregation, enabling easier placement in complex formworks compared to traditional concrete. Construction techniques for fiber-reinforced concrete often require adjustments in mixing time and equipment to ensure uniform fiber distribution, which differs from the standard procedures used in traditional concrete applications. This concrete variant also reduces the need for extensive reinforcement placement, streamlining construction processes and reducing labor intensity on site.

Cost Implications and Economic Considerations

Fiber-reinforced concrete typically incurs higher initial costs due to the addition of synthetic or steel fibers, which enhances tensile strength and durability compared to traditional concrete. The long-term economic benefits include reduced maintenance and repair expenses, extending the lifespan of structures and lowering total lifecycle costs. Investing in fiber-reinforced concrete often results in better cost efficiency for infrastructure projects requiring high performance and resilience under stress.

Applications in Modern Civil Engineering Projects

Fiber-reinforced concrete (FRC) enhances mechanical properties such as tensile strength, ductility, and crack resistance, making it ideal for applications in pavements, tunnels, and precast components in modern civil engineering projects. Traditional concrete remains widely used for structural elements like beams, columns, and foundations due to its compressive strength and cost-effectiveness. The integration of FRC in infrastructure projects improves durability and reduces maintenance, especially in high-stress environments such as industrial floors and bridge decks.

Sustainability and Environmental Impact

Fiber-reinforced concrete enhances sustainability by increasing durability and reducing the need for frequent repairs, which decreases overall material consumption and waste. It often incorporates recycled fibers, such as steel or synthetic fibers from industrial by-products, further lowering the environmental footprint compared to traditional concrete. Traditional concrete production generates significant CO2 emissions due to cement manufacturing, while fiber reinforcement extends service life and mitigates carbon impact by improving structural performance.

Maintenance Requirements and Lifespan

Fiber-reinforced concrete significantly reduces maintenance requirements due to its enhanced crack resistance and improved durability under stress, resulting in fewer repairs over time compared to traditional concrete. The integration of synthetic or steel fibers within the concrete matrix extends the lifespan by mitigating shrinkage, corrosion, and impact damage, often exceeding 50 years under optimal conditions. Traditional concrete typically demands more frequent upkeep and exhibits a shorter functional lifespan, especially in environments prone to heavy loads and weathering.

Future Trends in Concrete Technology

Future trends in concrete technology emphasize the increased use of fiber-reinforced concrete (FRC) due to its superior tensile strength, crack resistance, and durability compared to traditional concrete. Innovations in nanotechnology and advanced fiber materials, such as carbon and basalt fibers, are expected to enhance FRC performance, reducing maintenance costs and extending structural lifespan. The integration of smart sensors embedded in fiber-reinforced concrete further supports real-time monitoring and predictive maintenance, driving the development of more sustainable and resilient infrastructure.

Tensile strength differential

Fiber-reinforced concrete exhibits tensile strength improvements up to 3 times greater than traditional concrete due to embedded fibers that inhibit crack propagation.

Crack propagation control

Fiber-reinforced concrete significantly enhances crack propagation control by distributing tensile stresses through embedded fibers, reducing crack widths and improving durability compared to traditional concrete.

Modulus of rupture

Fiber-reinforced concrete exhibits a significantly higher modulus of rupture, typically improving flexural strength by 20-50% compared to traditional concrete.

Fiber dispersion uniformity

Fiber-reinforced concrete offers superior fiber dispersion uniformity compared to traditional concrete, enhancing structural integrity and crack resistance.

Flexural toughness enhancement

Fiber-reinforced concrete improves flexural toughness by increasing crack resistance and energy absorption compared to traditional concrete.

Shrinkage cracking mitigation

Fiber-reinforced concrete reduces shrinkage cracking by enhancing tensile strength and distributing stress, unlike traditional concrete which is more prone to crack formation due to lower crack resistance.

Reinforcement synergy

Fiber-reinforced concrete enhances traditional concrete's structural integrity by synergistically distributing tensile stresses and reducing crack propagation for superior durability.

Load-bearing ductility

Fiber-reinforced concrete exhibits significantly higher load-bearing ductility than traditional concrete due to the enhanced crack resistance and energy absorption provided by embedded fibers.

Post-cracking behavior

Fiber-reinforced concrete demonstrates superior post-cracking behavior through enhanced tensile strength and crack control compared to traditional concrete, which typically exhibits brittle failure after cracking.

Impact resistance augmentation

Fiber-reinforced concrete enhances impact resistance significantly by distributing stress more evenly and preventing crack propagation compared to traditional concrete.

Fiber-reinforced concrete vs Traditional concrete Infographic

njnir.com

njnir.com