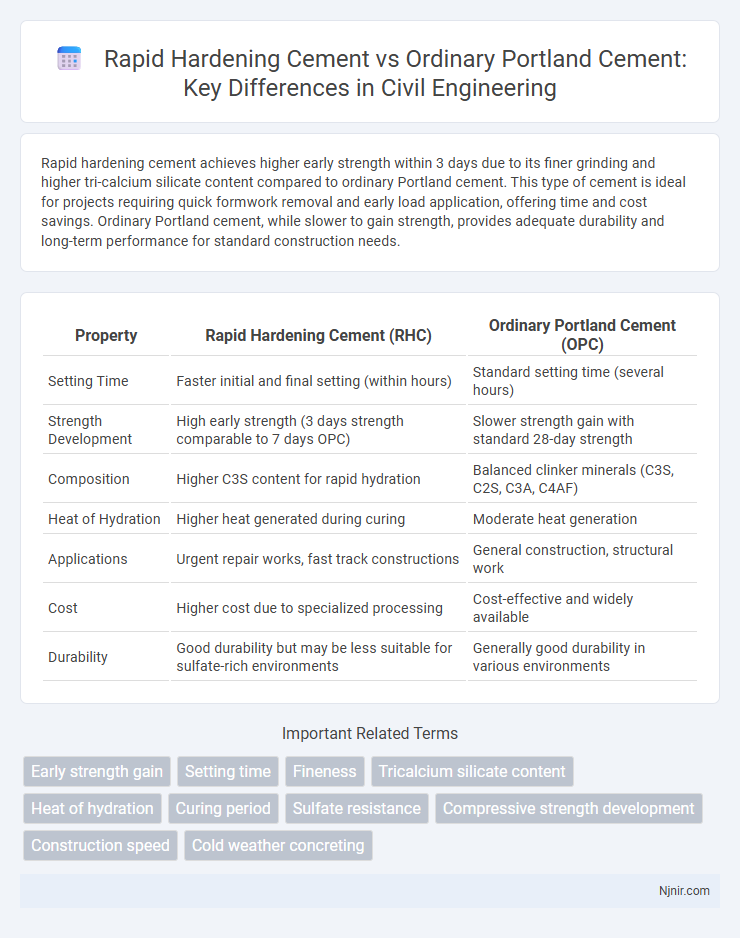

Rapid hardening cement achieves higher early strength within 3 days due to its finer grinding and higher tri-calcium silicate content compared to ordinary Portland cement. This type of cement is ideal for projects requiring quick formwork removal and early load application, offering time and cost savings. Ordinary Portland cement, while slower to gain strength, provides adequate durability and long-term performance for standard construction needs.

Table of Comparison

| Property | Rapid Hardening Cement (RHC) | Ordinary Portland Cement (OPC) |

|---|---|---|

| Setting Time | Faster initial and final setting (within hours) | Standard setting time (several hours) |

| Strength Development | High early strength (3 days strength comparable to 7 days OPC) | Slower strength gain with standard 28-day strength |

| Composition | Higher C3S content for rapid hydration | Balanced clinker minerals (C3S, C2S, C3A, C4AF) |

| Heat of Hydration | Higher heat generated during curing | Moderate heat generation |

| Applications | Urgent repair works, fast track constructions | General construction, structural work |

| Cost | Higher cost due to specialized processing | Cost-effective and widely available |

| Durability | Good durability but may be less suitable for sulfate-rich environments | Generally good durability in various environments |

Introduction to Cement Types in Construction

Rapid hardening cement gains strength much faster than ordinary Portland cement due to its higher percentage of tricalcium silicate, making it ideal for projects requiring early strength and quick formwork removal. Ordinary Portland cement, a commonly used construction material, hardens slowly and provides long-term strength and durability suitable for general construction purposes. Understanding the distinct hydration processes and setting times of these cement types is crucial for selecting the right cement in construction applications.

Composition Differences: Rapid Hardening vs Ordinary Portland Cement

Rapid hardening cement contains a higher percentage of tricalcium silicate (C3S) and finer particles compared to ordinary Portland cement, which accelerates the hydration process and strength development. Ordinary Portland cement typically has balanced proportions of tricalcium silicate, dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF), leading to slower strength gain. The elevated C3S content in rapid hardening cement enhances early strength, making it suitable for projects requiring quick setting and early load bearing.

Manufacturing Process Comparison

Rapid hardening cement is produced by grinding clinkers at a finer level and incorporating higher amounts of tricalcium silicate (C3S), enabling faster hydration and strength gain compared to ordinary Portland cement (OPC). The manufacturing process involves precise control of cooling rates to increase C3S formation, whereas OPC manufacturing typically emphasizes balanced cooling to achieve standard hydration rates. Energy consumption during grinding is higher for rapid hardening cement due to finer particle size requirements, impacting production efficiency and cost.

Setting Time and Early Strength Development

Rapid hardening cement exhibits a significantly shorter setting time, typically beginning initial set within 20 to 30 minutes, compared to ordinary Portland cement which takes around 45 minutes to several hours. Its early strength development is accelerated, achieving compressive strength of about 20 MPa within 24 hours, while ordinary Portland cement reaches similar strength only after 3 days. This rapid performance makes rapid hardening cement ideal for urgent repairs and fast-track construction projects.

Applications of Rapid Hardening Cement

Rapid hardening cement is widely used in construction projects requiring early strength development such as road repairs, precast concrete products, and emergency structures. Its ability to achieve high strength within 24 hours makes it ideal for reducing downtime in infrastructure maintenance and accelerating project timelines. This cement type is also preferred in cold weather concreting where quick setting prevents damage from freezing temperatures.

Common Uses of Ordinary Portland Cement

Ordinary Portland Cement (OPC) is widely used in construction projects such as residential buildings, bridges, highways, and infrastructure requiring long-term strength and durability. It is favored for applications like concrete production, mortar, plaster, and grouting due to its reliable setting time and strength development. OPC's versatility and cost-effectiveness make it ideal for general construction compared to rapid hardening cement, which is reserved for urgent repairs and fast-track projects.

Advantages of Rapid Hardening Cement in Projects

Rapid hardening cement significantly reduces setting time, enabling faster construction progress and early removal of formwork compared to ordinary Portland cement. Its higher early strength development enhances project efficiency, allowing for quicker load application and structural use. This cement type also improves resistance to early-age cracking, supporting durability in time-sensitive infrastructure projects.

Limitations and Considerations for Each Cement Type

Rapid hardening cement offers early strength gain but may cause increased shrinkage and thermal cracking, limiting its use in large-scale structures prone to temperature variation. Ordinary Portland cement provides better durability and workability over time yet requires longer curing periods, which can delay construction schedules. Both cement types demand careful selection based on environmental exposure, structural requirements, and project timelines to optimize performance and longevity.

Cost Implications and Economic Factors

Rapid hardening cement typically incurs higher initial costs compared to ordinary Portland cement due to its specialized manufacturing processes and expedited strength development properties. However, its quicker setting time can lead to reduced construction durations, lowering labor and equipment rental expenses, which may offset the increased material cost in fast-paced projects. In long-term economic terms, projects requiring early load application benefit from rapid hardening cement's performance, potentially decreasing overall project timelines and associated financial risks.

Choosing the Right Cement for Your Civil Engineering Project

Rapid hardening cement achieves high strength within 3 days, ideal for projects requiring quick formwork removal and early load application, whereas ordinary Portland cement (OPC) reaches strength gradually over 28 days. Selecting the right cement depends on project timelines, environmental conditions, and structural requirements, with rapid hardening cement suitable for cold weather concreting and emergency repairs. Consider factors such as setting time, compressive strength, and cost-effectiveness to optimize durability and performance in civil engineering applications.

Early strength gain

Rapid hardening cement achieves significantly higher early strength gain within the first 24 hours compared to ordinary Portland cement, making it ideal for time-sensitive construction projects.

Setting time

Rapid hardening cement achieves initial and final setting times significantly faster than ordinary Portland cement, typically within 30-60 minutes for initial setting compared to 45-120 minutes.

Fineness

Rapid hardening cement exhibits significantly higher fineness, typically around 320-350 m2/kg Blaine surface area, compared to ordinary Portland cement's 225-280 m2/kg, enabling faster hydration and early strength development.

Tricalcium silicate content

Rapid hardening cement contains a higher percentage of tricalcium silicate (C3S), typically around 60-70%, compared to ordinary Portland cement, which usually contains about 50-60%, resulting in faster strength development within the first few days.

Heat of hydration

Rapid hardening cement generates significantly higher heat of hydration than ordinary Portland cement, accelerating strength gain and reducing setting time for faster project completion.

Curing period

Rapid hardening cement reaches 70% of its strength within 3 days of curing, significantly faster than ordinary Portland cement, which typically requires 28 days to achieve comparable strength.

Sulfate resistance

Rapid hardening cement offers lower sulfate resistance compared to ordinary Portland cement due to its higher C3A content, making OPC more suitable for sulfate-rich environments.

Compressive strength development

Rapid hardening cement achieves higher compressive strength within 3 days, often exceeding 20 MPa, compared to ordinary Portland cement which typically reaches similar strength levels around 7 days.

Construction speed

Rapid hardening cement achieves initial set within 2-4 hours, significantly accelerating construction speed compared to ordinary Portland cement, which typically sets in 6-12 hours.

Cold weather concreting

Rapid hardening cement accelerates strength development in cold weather concreting by reaching higher early strength faster than ordinary Portland cement, reducing curing time and minimizing frost damage risks.

Rapid hardening cement vs ordinary Portland cement Infographic

njnir.com

njnir.com