Tunnel Boring Machines (TBMs) provide a continuous, efficient excavation process with minimal disturbance to surrounding geology, making them ideal for urban environments and long tunnels. Drill and blast methods offer greater flexibility in varying rock conditions and complex alignments, often resulting in lower initial equipment costs and shorter mobilization times. Selecting between TBM and drill and blast depends on factors like tunnel length, rock hardness, environmental impact, and project budget.

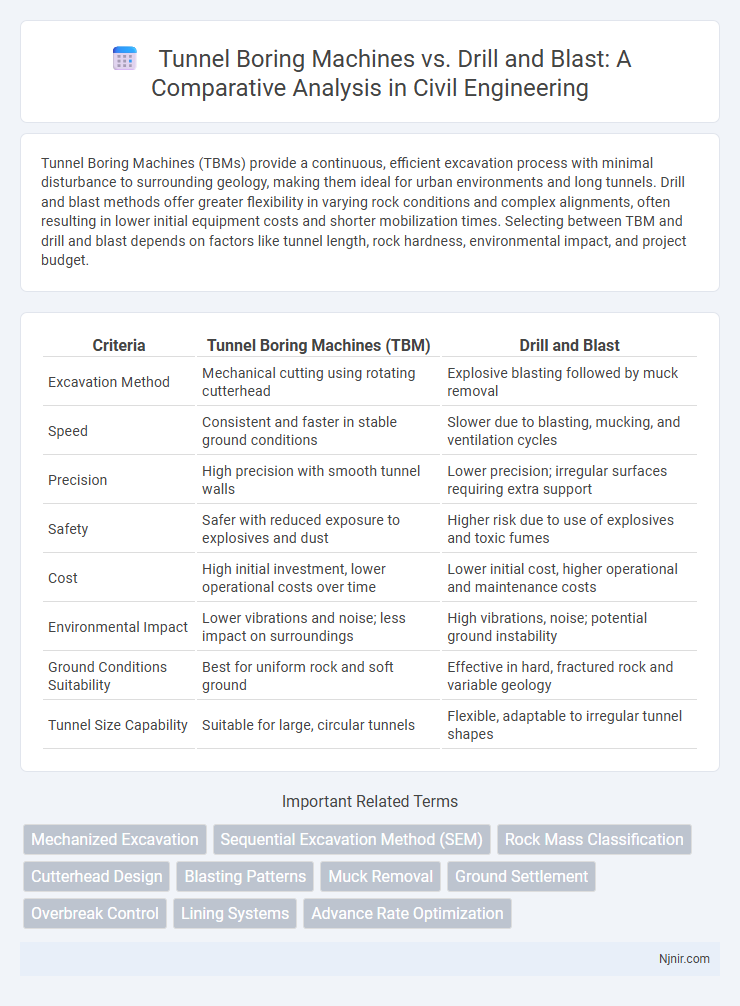

Table of Comparison

| Criteria | Tunnel Boring Machines (TBM) | Drill and Blast |

|---|---|---|

| Excavation Method | Mechanical cutting using rotating cutterhead | Explosive blasting followed by muck removal |

| Speed | Consistent and faster in stable ground conditions | Slower due to blasting, mucking, and ventilation cycles |

| Precision | High precision with smooth tunnel walls | Lower precision; irregular surfaces requiring extra support |

| Safety | Safer with reduced exposure to explosives and dust | Higher risk due to use of explosives and toxic fumes |

| Cost | High initial investment, lower operational costs over time | Lower initial cost, higher operational and maintenance costs |

| Environmental Impact | Lower vibrations and noise; less impact on surroundings | High vibrations, noise; potential ground instability |

| Ground Conditions Suitability | Best for uniform rock and soft ground | Effective in hard, fractured rock and variable geology |

| Tunnel Size Capability | Suitable for large, circular tunnels | Flexible, adaptable to irregular tunnel shapes |

Introduction to Tunnel Construction Methods

Tunnel Boring Machines (TBMs) and Drill and Blast are two primary methods in tunnel construction, each suited to different geological conditions and project requirements. TBMs offer continuous excavation with minimal surface disruption, ideal for long, uniform tunnels in stable rock, while Drill and Blast allows for flexibility in complex or variable geology by creating controlled explosions to fracture rock. Selecting the appropriate method depends on factors such as tunnel length, geology, environmental constraints, and project timelines.

Overview of Tunnel Boring Machines (TBMs)

Tunnel Boring Machines (TBMs) are advanced engineering tools designed for efficient and precise excavation of tunnels through various soil and rock conditions. These machines integrate cutting heads, conveyor systems, and lining installation mechanisms to provide continuous, safer tunneling operations with minimal surface disruption. TBMs offer higher productivity and reduced environmental impact compared to traditional drill and blast methods, making them ideal for urban and long-distance tunneling projects.

Understanding the Drill and Blast Method

The Drill and Blast method involves drilling holes into rock surfaces followed by the placement and controlled detonation of explosives to fracture the rock, facilitating excavation in tunnel construction. This traditional technique allows for flexibility in varied geological conditions and is cost-effective for shorter tunnel drives or complex alignments where mechanized equipment faces challenges. Compared to Tunnel Boring Machines (TBMs), Drill and Blast offers adaptability but requires meticulous planning to manage vibrations, ventilation, and safety during blasting operations.

Key Differences Between TBM and Drill and Blast

Tunnel Boring Machines (TBM) offer continuous excavation with reduced ground disturbance compared to the intermittent and explosive-based Drill and Blast method, resulting in smoother tunnel walls and faster tunnel completion times. TBM is ideal for stable geological conditions and longer tunnel projects, whereas Drill and Blast is more flexible for varied rock types and shorter or complex tunnel alignments. The mechanized nature of TBMs significantly enhances worker safety by minimizing exposure to dust, vibration, and flying debris typical in Drill and Blast operations.

Geotechnical Suitability for Each Method

Tunnel Boring Machines (TBMs) excel in homogeneous and stable ground conditions such as soft soils, clay, and medium-strength rock, providing precise excavation with minimal disturbance. Drill and Blast methods suit hard, fractured, and highly variable geological formations where TBM operation may be hindered by abrasiveness or heterogeneous rock layers. Geotechnical assessments prioritize rock mass strength, joint spacing, and groundwater conditions to determine the most cost-effective and safe tunneling technique.

Construction Speed and Project Timeline

Tunnel Boring Machines (TBMs) offer faster excavation speeds, averaging 10-15 meters per day in optimal conditions, compared to drill and blast methods, which typically achieve 1-3 meters per day. TBMs provide continuous tunneling with reduced downtime, significantly shortening project timelines for long, consistent tunnels. Drill and blast is more flexible in variable geology but generally results in longer construction durations due to sequential blasting, muck removal, and ventilation requirements.

Cost Comparison: TBM vs Drill and Blast

Tunnel Boring Machines (TBMs) generally require higher upfront capital investment due to advanced technology and machinery costs, making them more cost-effective for long tunnels exceeding several kilometers. Drill and Blast methods incur lower initial expenses but often result in higher operational costs, including increased labor, slower progress, and more frequent equipment replacement, which can raise total project costs for extensive tunneling projects. Cost efficiency for TBM versus Drill and Blast heavily depends on tunnel length, geology, and project scale, with TBMs favored for large-scale urban and high-volume excavations.

Environmental Impact and Safety Considerations

Tunnel Boring Machines (TBMs) significantly reduce environmental impact by minimizing noise, vibration, and air pollution compared to the Drill and Blast method, which generates extensive dust, toxic gases, and ground disturbance. TBMs enhance safety by providing continuous support to tunnel walls, lowering the risk of collapses, while Drill and Blast pose higher hazards due to explosives, flying debris, and ground instability. Choosing TBMs promotes sustainable tunneling practices and improves worker safety in urban and environmentally sensitive areas.

Case Studies: Successful Applications

Case studies highlight Tunnel Boring Machines (TBMs) effectively constructing long, uniform tunnels such as the Gotthard Base Tunnel in Switzerland, where precision and speed minimized environmental impact. Drill and Blast techniques excel in complex, irregular geology like Norway's Oslo Metro expansion, allowing flexibility in shaping and stabilizing challenging rock formations. These examples demonstrate TBMs' advantages in efficiency and continuous excavation, while Drill and Blast offers adaptability in variable geological conditions.

Choosing the Right Method for Your Project

Selecting the appropriate excavation method depends on project scale, geology, and environmental impact. Tunnel Boring Machines (TBMs) offer precise, continuous excavation ideal for long tunnels in stable ground, minimizing surface disruption. Drill and Blast excels in hard rock and variable geology, providing flexibility and cost-efficiency for shorter tunnels or uneven terrain.

Mechanized Excavation

Tunnel Boring Machines (TBMs) enable faster, safer, and more precise mechanized excavation compared to Drill and Blast methods by continuously cutting through rock with minimal vibration and disruption.

Sequential Excavation Method (SEM)

The Sequential Excavation Method (SEM) offers flexible, controlled excavation for complex geology, contrasting with Tunnel Boring Machines (TBMs) which provide continuous, mechanized tunneling, while Drill and Blast relies on controlled explosions ideal for hard rock but less precise excavation.

Rock Mass Classification

Tunnel Boring Machines achieve higher efficiency in homogeneous rock masses with consistent strength, while Drill and Blast methods adapt better to heterogeneous or highly fractured rock mass classifications.

Cutterhead Design

Tunnel Boring Machines feature advanced cutterhead designs with rotating discs and cutting tools optimized for consistent rock excavation, offering increased precision and reduced vibration compared to the variable-impact approach of Drill and Blast methods.

Blasting Patterns

Tunnel boring machines provide continuous excavation, while drill and blast rely on precisely designed blasting patterns to efficiently fragment rock and control tunnel profile.

Muck Removal

Tunnel Boring Machines enable continuous, automated muck removal through conveyor belts, significantly increasing efficiency compared to the intermittent, manual muck extraction in Drill and Blast methods.

Ground Settlement

Tunnel Boring Machines minimize ground settlement significantly compared to Drill and Blast methods due to their controlled excavation and continuous support systems.

Overbreak Control

Tunnel Boring Machines provide superior overbreak control compared to Drill and Blast methods by offering precise excavation with minimized rock damage and reduced geometric deviations.

Lining Systems

Tunnel Boring Machines provide continuous precast segment lining systems that enhance structural integrity and speed, while Drill and Blast methods rely on shotcrete and steel ribs requiring longer curing times and more manual installation.

Advance Rate Optimization

Tunnel Boring Machines achieve higher advance rate optimization compared to drill and blast methods by providing continuous excavation, precise cutting, and reduced cycle times in consistent geological conditions.

Tunnel Boring Machines vs Drill and Blast Infographic

njnir.com

njnir.com