LED street lighting offers superior energy efficiency and longer lifespan compared to sodium vapor lighting, resulting in significant cost savings for municipal budgets. It provides better color rendering and uniform illumination, enhancing nighttime visibility and safety on roads. Furthermore, LED lights reduce maintenance requirements and environmental impact due to lower power consumption and the absence of hazardous materials.

Table of Comparison

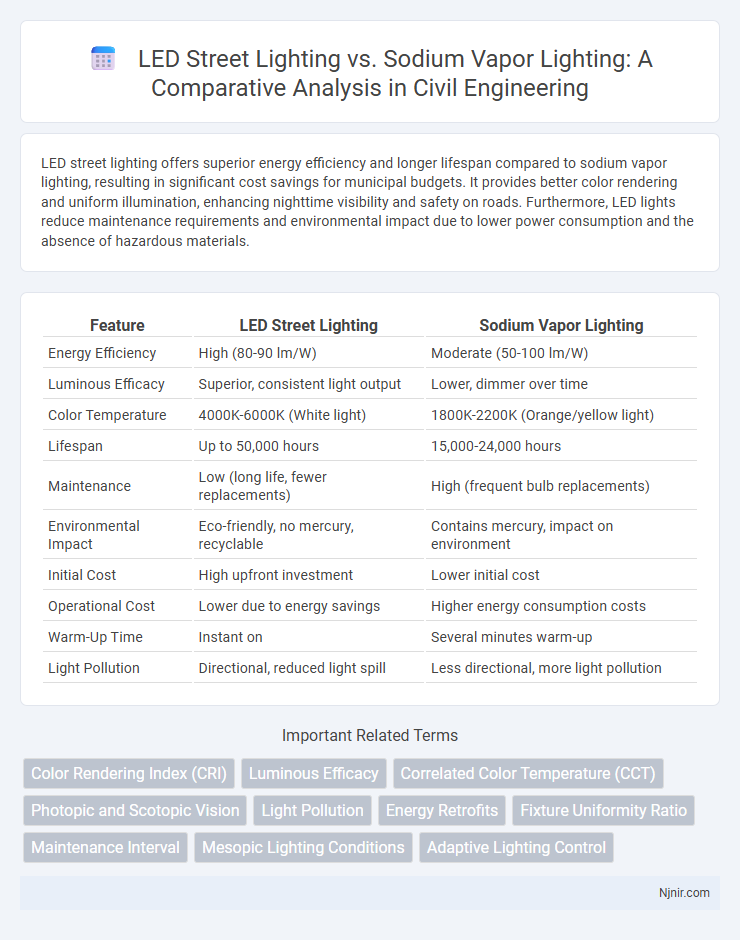

| Feature | LED Street Lighting | Sodium Vapor Lighting |

|---|---|---|

| Energy Efficiency | High (80-90 lm/W) | Moderate (50-100 lm/W) |

| Luminous Efficacy | Superior, consistent light output | Lower, dimmer over time |

| Color Temperature | 4000K-6000K (White light) | 1800K-2200K (Orange/yellow light) |

| Lifespan | Up to 50,000 hours | 15,000-24,000 hours |

| Maintenance | Low (long life, fewer replacements) | High (frequent bulb replacements) |

| Environmental Impact | Eco-friendly, no mercury, recyclable | Contains mercury, impact on environment |

| Initial Cost | High upfront investment | Lower initial cost |

| Operational Cost | Lower due to energy savings | Higher energy consumption costs |

| Warm-Up Time | Instant on | Several minutes warm-up |

| Light Pollution | Directional, reduced light spill | Less directional, more light pollution |

Introduction to Street Lighting Technologies

LED street lighting offers superior energy efficiency, longer lifespan, and enhanced color rendering compared to traditional sodium vapor lighting. Sodium vapor lamps, including high-pressure and low-pressure types, have been widely used for their high luminous efficacy but suffer from poor color quality and longer warm-up times. Modern urban infrastructure increasingly favors LED technology due to its instant illumination capability, reduced maintenance costs, and ability to integrate smart controls for adaptive lighting management.

Overview of LED and Sodium Vapor Lighting

LED street lighting utilizes light-emitting diodes to produce bright, energy-efficient illumination with longer lifespans and lower maintenance costs compared to traditional lighting technologies. Sodium vapor lighting, available in low and high pressure varieties, emits a characteristic yellow-orange glow due to the excitation of sodium atoms, widely used for its high luminous efficacy but suffers from color rendering limitations and shorter operational life. The increasing adoption of LED technology in street lighting is driven by superior energy savings, enhanced durability, and better environmental performance relative to sodium vapor lamps.

Energy Efficiency Comparison

LED street lighting offers significantly higher energy efficiency compared to sodium vapor lighting, reducing energy consumption by up to 50-70%. LEDs convert more electrical energy into visible light with less heat production, resulting in reduced power usage and lower maintenance costs. Sodium vapor lamps consume more energy due to their higher wattage requirements and lower luminous efficacy, making LEDs a more sustainable choice for urban lighting infrastructure.

Lifespan and Maintenance Requirements

LED street lighting typically offers a lifespan of 50,000 to 100,000 hours, significantly outlasting sodium vapor lights, which average 24,000 hours. Maintenance requirements for LEDs are minimal due to their robust solid-state technology, resulting in reduced costs and less frequent replacements compared to sodium vapor lamps that often require ballast replacements and more frequent bulb changes. The extended lifespan and lower maintenance demands make LED street lighting a more cost-effective and sustainable option for urban infrastructure.

Light Quality and Color Rendering

LED street lighting offers superior light quality with high color rendering index (CRI) values typically above 80, producing clear, natural illumination that enhances visibility and safety. Sodium vapor lighting, especially low-pressure sodium types, has poor color rendering with CRI values near zero, resulting in monochromatic yellow-orange light that distorts colors and reduces visual clarity. Enhanced color accuracy and brightness uniformity of LEDs contribute to better pedestrian and driver perception compared to the limited spectrum and color distortion of sodium vapor lamps.

Environmental Impact Assessment

LED street lighting significantly reduces energy consumption by up to 50-70% compared to sodium vapor lighting, leading to lower greenhouse gas emissions and a smaller carbon footprint. LEDs contain no hazardous materials like mercury found in sodium vapor lamps, minimizing environmental contamination risks during disposal. The longer lifespan of LED fixtures also decreases waste generation and maintenance frequency, enhancing overall sustainability in urban lighting systems.

Cost Analysis: Installation and Operation

LED street lighting offers lower installation costs due to simpler fixtures and longer lifespans, reducing the frequency and expense of replacements compared to sodium vapor lighting. Operational costs are significantly reduced with LEDs, as they consume 30-50% less energy and require less maintenance, translating to substantial savings in electricity and labor. Sodium vapor lights, while initially cheaper, involve higher power consumption and more frequent bulb replacement, increasing total cost of ownership over time.

Safety and Visibility Considerations

LED street lighting offers superior color rendering and uniform light distribution compared to sodium vapor lighting, enhancing pedestrian and driver visibility during nighttime. The high-quality white light of LEDs improves contrast and reduces glare, contributing to better hazard detection and overall road safety. In contrast, sodium vapor lamps emit a yellow-orange hue with lower color fidelity, which may impair depth perception and slow reaction times in critical situations.

Retrofit Challenges and Solutions

Retrofitting LED street lighting into existing sodium vapor fixtures presents challenges such as compatibility with legacy wiring, ballast removal, and ensuring uniform light distribution. Solutions include using LED retrofit kits designed to bypass or replace ballasts, implementing modular LED units that fit existing poles, and upgrading control systems for dimming and smart management. Addressing thermal management and ensuring compliance with local lighting standards are crucial for long-term performance and maintenance efficiency.

Future Trends in Street Lighting Systems

LED street lighting is rapidly emerging as the preferred technology due to its energy efficiency and longer lifespan compared to sodium vapor lighting, which tends to consume more power and have shorter maintenance intervals. Future trends in street lighting systems emphasize smart integration, including adaptive dimming, IoT connectivity, and real-time data analytics to optimize energy use and enhance urban safety. Advancements in LED technology will drive widespread adoption, phasing out sodium vapor lamps in favor of environmentally sustainable and cost-effective solutions.

Color Rendering Index (CRI)

LED street lighting typically offers a higher Color Rendering Index (CRI) of 70-90, enhancing color accuracy and visibility compared to sodium vapor lighting, which generally has a lower CRI around 20-30.

Luminous Efficacy

LED street lighting offers significantly higher luminous efficacy, typically ranging from 100 to 150 lumens per watt, compared to sodium vapor lamps which average around 70 to 120 lumens per watt, resulting in improved energy efficiency and reduced operational costs.

Correlated Color Temperature (CCT)

LED street lighting offers adjustable Correlated Color Temperature (CCT) ranging from 2700K to 6500K, providing better color rendering and energy efficiency compared to fixed high CCT values typically found in sodium vapor lighting.

Photopic and Scotopic Vision

LED street lighting enhances visual clarity and energy efficiency by optimizing photopic and scotopic vision better than sodium vapor lighting, which primarily supports photopic vision but provides lower scotopic sensitivity for nighttime conditions.

Light Pollution

LED street lighting reduces light pollution more effectively than sodium vapor lighting by providing directional illumination with minimal skyglow and glare.

Energy Retrofits

Energy retrofits using LED street lighting reduce energy consumption by up to 50% compared to traditional sodium vapor lighting while extending fixture lifespan and lowering maintenance costs.

Fixture Uniformity Ratio

LED street lighting achieves a lower Fixture Uniformity Ratio of 1.5 to 3.0 compared to sodium vapor lighting's typical ratio of 3.5 to 5.0, resulting in more consistent and evenly distributed illumination.

Maintenance Interval

LED street lighting requires maintenance intervals up to 10 times longer than sodium vapor lighting, significantly reducing operational costs and downtime.

Mesopic Lighting Conditions

LED street lighting offers improved visibility and energy efficiency in mesopic lighting conditions by delivering better color rendering and uniform illumination compared to traditional sodium vapor lighting.

Adaptive Lighting Control

Adaptive Lighting Control in LED street lighting enhances energy efficiency and reduces light pollution by dynamically adjusting brightness based on real-time traffic and environmental conditions, outperforming traditional sodium vapor lighting systems.

LED street lighting vs sodium vapor lighting Infographic

njnir.com

njnir.com