3D printed bridges offer rapid construction and complex geometric designs that reduce material waste compared to traditional cast-in-place bridges. These structures provide enhanced durability through precise layering techniques, eliminating formwork and lowering labor costs. Cast-in-place bridges remain favored for their proven reliability and adaptability in diverse site conditions, but 3D printing is rapidly advancing as a sustainable alternative in civil engineering.

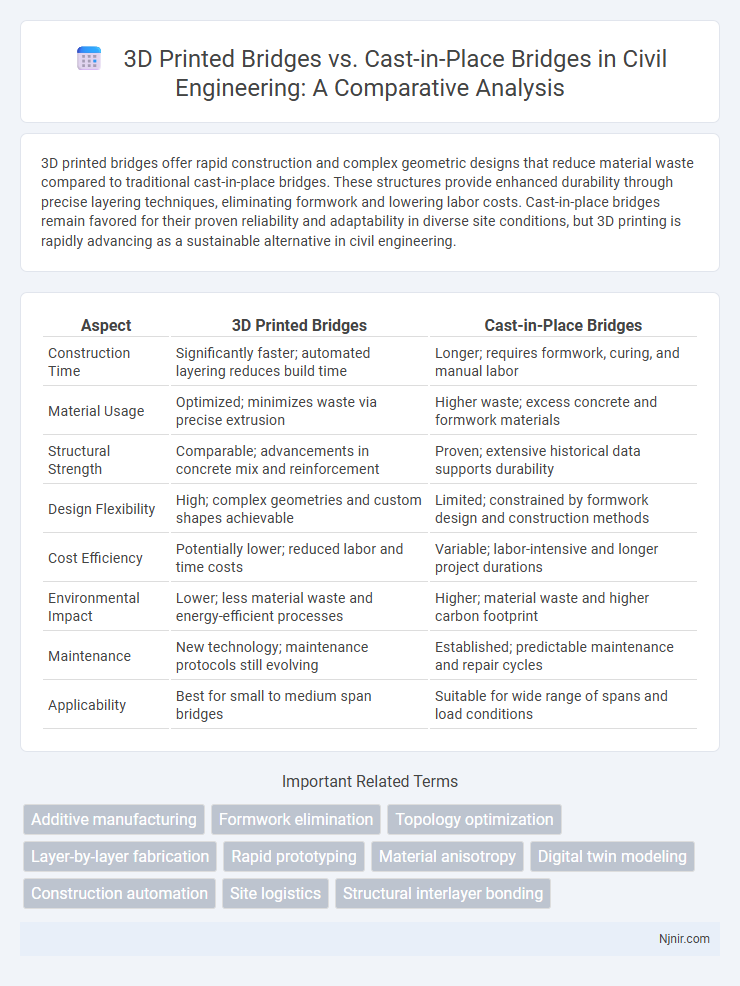

Table of Comparison

| Aspect | 3D Printed Bridges | Cast-in-Place Bridges |

|---|---|---|

| Construction Time | Significantly faster; automated layering reduces build time | Longer; requires formwork, curing, and manual labor |

| Material Usage | Optimized; minimizes waste via precise extrusion | Higher waste; excess concrete and formwork materials |

| Structural Strength | Comparable; advancements in concrete mix and reinforcement | Proven; extensive historical data supports durability |

| Design Flexibility | High; complex geometries and custom shapes achievable | Limited; constrained by formwork design and construction methods |

| Cost Efficiency | Potentially lower; reduced labor and time costs | Variable; labor-intensive and longer project durations |

| Environmental Impact | Lower; less material waste and energy-efficient processes | Higher; material waste and higher carbon footprint |

| Maintenance | New technology; maintenance protocols still evolving | Established; predictable maintenance and repair cycles |

| Applicability | Best for small to medium span bridges | Suitable for wide range of spans and load conditions |

Introduction to 3D Printed and Cast-in-Place Bridges

3D printed bridges utilize advanced additive manufacturing techniques to create complex, lightweight structures with reduced material waste, offering innovative design flexibility and faster construction timelines. Cast-in-place bridges rely on traditional methods, pouring concrete into formwork on-site to form sturdy and durable structures with proven long-term performance and well-understood maintenance procedures. Comparing these technologies highlights the shift toward digital fabrication in infrastructure, balancing cutting-edge efficiency against the reliability of established construction practices.

Material Innovations in Bridge Construction

3D printed bridges utilize advanced composite materials such as fiber-reinforced polymers and special concrete mixes that enhance durability and reduce weight compared to traditional cast-in-place bridges. These materials enable complex geometric designs and rapid curing processes, significantly cutting construction time and labor costs. In contrast, cast-in-place bridges primarily rely on conventional concrete and steel reinforcements, which offer proven structural integrity but lack the material adaptability and customization potential found in 3D printing innovations.

Speed of Construction: 3D Printing vs Traditional Casting

3D printed bridges significantly reduce construction time by fabricating components layer-by-layer directly on-site, eliminating the need for formwork and curing periods inherent in cast-in-place methods. The additive manufacturing process allows for continuous construction, speeding up project timelines compared to the sequential steps of traditional casting. This acceleration benefits infrastructure projects by minimizing traffic disruptions and lowering labor costs.

Structural Performance and Durability Comparison

3D printed bridges demonstrate enhanced structural performance through precise material placement, resulting in optimized load distribution and reduced stress concentrations compared to traditional cast-in-place bridges. Their layered construction enables intricate reinforcement designs that improve durability by minimizing crack propagation and corrosion risks. Cast-in-place bridges, while proven, often face challenges with curing variability and uniformity that can impact long-term structural integrity and maintenance costs.

Cost Efficiency and Resource Utilization

3D printed bridges offer significant cost efficiency by reducing labor expenses and material waste through precise additive manufacturing, enabling faster construction cycles compared to cast-in-place bridges, which often incur higher labor and formwork costs. Resource utilization in 3D printing optimizes concrete use with minimal excess, enhancing sustainability, while cast-in-place methods typically involve larger material volumes and more extensive on-site equipment. The integration of 3D printing technology contributes to reduced construction timelines and lower overall project costs, positioning it as a competitive alternative in modern bridge engineering.

Environmental Impact and Sustainability Factors

3D printed bridges significantly reduce environmental impact by minimizing material waste and using eco-friendly composites, unlike traditional cast-in-place bridges that rely heavily on concrete, a major source of CO2 emissions. The additive manufacturing process consumes less energy through precise layering and reduces the need for formwork and heavy machinery, enhancing sustainability. Moreover, 3D printed bridges offer potential for rapid construction and longer lifespans due to optimized structural designs, contributing to lower carbon footprints over their service life.

Design Flexibility and Architectural Possibilities

3D printed bridges offer unparalleled design flexibility by enabling complex geometries and custom shapes that traditional cast-in-place bridges cannot easily achieve. The additive manufacturing process allows for intricate architectural details and organic forms that enhance aesthetic appeal while optimizing material usage. Cast-in-place bridges, constrained by formwork and conventional construction methods, typically follow more standardized designs that limit architectural creativity and complexity.

Quality Control and Precision in Construction

3D printed bridges offer enhanced quality control through automated, layer-by-layer fabrication that minimizes human error and ensures consistent material application, leading to superior precision in complex structural details. In contrast, cast-in-place bridges rely heavily on manual processes, which may introduce variability in concrete mix, placement, and curing, affecting overall uniformity and structural integrity. The advanced digital control in 3D printing facilitates real-time adjustments and accurate replication of designs, significantly improving the precision and reliability of bridge components compared to traditional cast-in-place methods.

Challenges and Limitations of Each Method

3D printed bridges face challenges in material durability and structural certification due to limited long-term performance data and regulatory standards lagging behind innovation. Cast-in-place bridges encounter limitations such as extended construction time, high labor costs, and environmental concerns from concrete curing emissions and formwork waste. Both methods struggle with scalability and complex geometries, but 3D printing offers potential for rapid prototyping while cast-in-place remains dominant for large-scale, standardized infrastructure.

Future Trends in Bridge Construction Technologies

3D printed bridges offer faster construction times and reduced material waste compared to traditional cast-in-place bridges, signaling a shift towards more sustainable infrastructure development. Advances in additive manufacturing allow for complex, customized designs that improve load distribution and durability. The integration of smart sensors in 3D printed components is poised to enhance real-time monitoring and maintenance, driving future trends in intelligent bridge construction technologies.

Additive manufacturing

Additive manufacturing enables 3D printed bridges to achieve complex geometries, reduced material waste, and faster construction compared to traditional cast-in-place bridges.

Formwork elimination

3D printed bridges eliminate the need for traditional formwork, reducing construction time and material waste compared to cast-in-place bridges.

Topology optimization

Topology optimization in 3D printed bridges enables intricate, material-efficient designs unattainable by cast-in-place bridges, significantly reducing weight and enhancing structural performance.

Layer-by-layer fabrication

3D printed bridges use precise layer-by-layer fabrication to reduce material waste and construction time compared to traditional cast-in-place bridges.

Rapid prototyping

3D printed bridges enable rapid prototyping with significantly reduced construction time and material waste compared to traditional cast-in-place bridges.

Material anisotropy

3D printed bridges exhibit significant material anisotropy due to layer-by-layer deposition, resulting in directional strength variations, whereas cast-in-place bridges typically have more isotropic material properties owing to uniform concrete curing.

Digital twin modeling

Digital twin modeling enhances the design, monitoring, and maintenance of 3D printed bridges by enabling real-time simulation and predictive analysis, outperforming traditional cast-in-place bridge approaches in efficiency and adaptability.

Construction automation

3D printed bridges reduce construction time and labor costs through automated layer-by-layer fabrication, while cast-in-place bridges rely heavily on manual labor and formwork, limiting automation efficiency.

Site logistics

3D printed bridges streamline site logistics by minimizing material storage, reducing construction time, and requiring less heavy machinery compared to cast-in-place bridges.

Structural interlayer bonding

3D printed bridges exhibit improved structural interlayer bonding due to precise layer-by-layer material deposition, enhancing durability compared to the often variable bonding quality in cast-in-place bridges.

3D printed bridges vs cast-in-place bridges Infographic

njnir.com

njnir.com