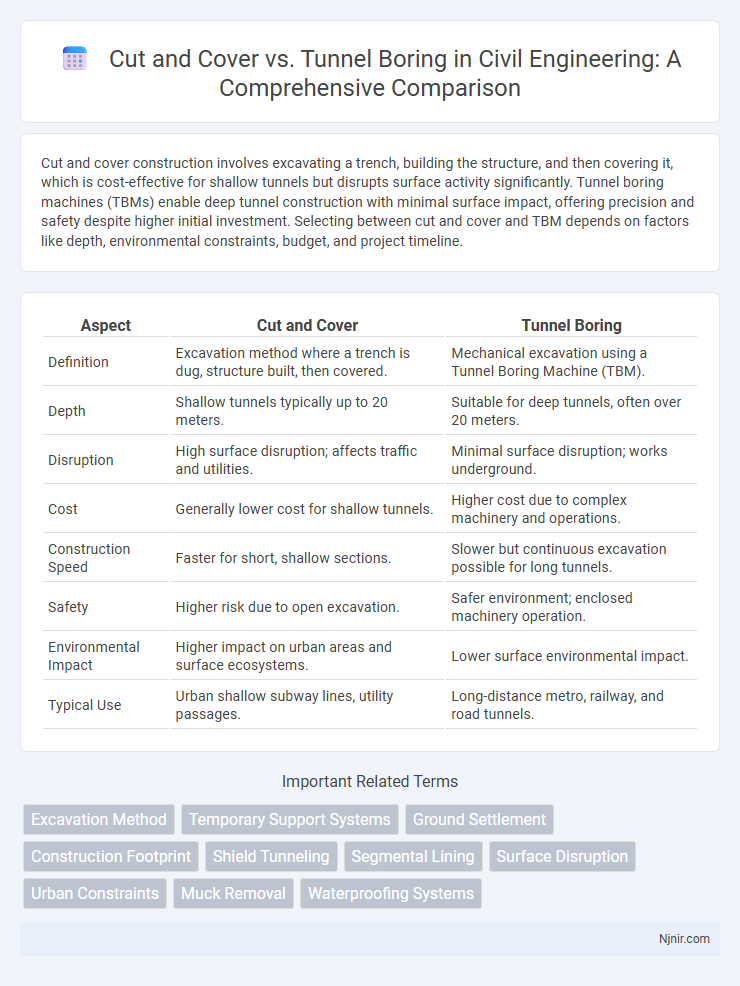

Cut and cover construction involves excavating a trench, building the structure, and then covering it, which is cost-effective for shallow tunnels but disrupts surface activity significantly. Tunnel boring machines (TBMs) enable deep tunnel construction with minimal surface impact, offering precision and safety despite higher initial investment. Selecting between cut and cover and TBM depends on factors like depth, environmental constraints, budget, and project timeline.

Table of Comparison

| Aspect | Cut and Cover | Tunnel Boring |

|---|---|---|

| Definition | Excavation method where a trench is dug, structure built, then covered. | Mechanical excavation using a Tunnel Boring Machine (TBM). |

| Depth | Shallow tunnels typically up to 20 meters. | Suitable for deep tunnels, often over 20 meters. |

| Disruption | High surface disruption; affects traffic and utilities. | Minimal surface disruption; works underground. |

| Cost | Generally lower cost for shallow tunnels. | Higher cost due to complex machinery and operations. |

| Construction Speed | Faster for short, shallow sections. | Slower but continuous excavation possible for long tunnels. |

| Safety | Higher risk due to open excavation. | Safer environment; enclosed machinery operation. |

| Environmental Impact | Higher impact on urban areas and surface ecosystems. | Lower surface environmental impact. |

| Typical Use | Urban shallow subway lines, utility passages. | Long-distance metro, railway, and road tunnels. |

Introduction to Cut and Cover and Tunnel Boring Methods

Cut and cover is an excavation technique where a trench is dug from the surface, the tunnel structure is built within the trench, and then it is covered with soil to restore the surface. Tunnel boring involves the use of a Tunnel Boring Machine (TBM) that excavates underground tunnels with minimal surface disruption by cutting through soil and rock. Both methods are essential in urban infrastructure projects, each suited to different geological conditions, depth requirements, and environmental constraints.

Historical Evolution of Urban Tunneling Techniques

Cut and cover tunneling originated in the early 19th century as a straightforward excavation method for shallow subway construction, exemplified by London's Metropolitan Railway in 1863. Tunnel boring machines (TBMs), developed in the mid-20th century, revolutionized urban tunneling by enabling deep, precise, and less disruptive excavations, evident in projects like the Channel Tunnel completed in 1994. The historical evolution reflects a shift from surface disruption-heavy techniques to advanced mechanized methods that accommodate increasing urban density and complex geological challenges.

Key Differences Between Cut and Cover and Tunnel Boring

Cut and cover construction involves excavating a trench from the surface, building the tunnel structure, and then covering it, making it suitable for shallow tunnels with minimal underground obstacles. Tunnel boring machines (TBMs) enable the creation of deep tunnels through various soil and rock types with minimal surface disruption but require higher initial investment and longer setup times. Key differences include depth capability, construction speed, cost, environmental impact, and suitability for different geological conditions.

Suitability Based on Geotechnical Conditions

Cut and cover construction excels in shallow, stable soil environments with low groundwater levels, where surface disruption is manageable and excavation is straightforward. Tunnel boring machines (TBMs) offer superior performance in deep, complex geotechnical conditions, including hard rock, high groundwater pressure, and urban settings with limited surface access. Selection depends on soil composition, depth, groundwater presence, and urban impact, with cut and cover suited for softer, less complex geologies and TBMs preferred for deeper, more challenging subsurface profiles.

Environmental Impact of Each Tunneling Method

Cut and cover tunneling often results in significant surface disruption, leading to habitat destruction, increased noise pollution, and dust emissions, impacting local ecosystems and urban environments. Tunnel boring machines (TBMs) minimize surface disturbance by excavating underground with precision, reducing noise and air pollution and preserving surface areas, but they can still generate spoil material that requires proper disposal. Environmental impact assessments typically favor tunnel boring for projects in densely populated or environmentally sensitive areas due to its lower overall ecological footprint and reduced impact on surface-level flora and fauna.

Construction Timeframes: Speed and Scheduling

Cut and cover construction typically allows for faster project completion in shallow-depth applications due to simpler excavation and immediate surface restoration, often reducing overall timeframes compared to tunnel boring machines (TBMs). Tunnel boring offers more predictable scheduling for deeper or longer tunnels by minimizing surface disruptions and enabling continuous excavation, though initial setup and machine assembly can extend lead times. Project speed and scheduling depend heavily on site conditions, tunnel length, and urban constraints influencing the choice between cut and cover or TBM methods.

Cost Comparison: Cut and Cover vs Tunnel Boring

Cut and cover construction generally incurs lower initial costs compared to tunnel boring machines (TBMs) due to simpler excavation and less specialized equipment, making it cost-effective for shallow tunnels. Tunnel boring presents higher upfront expenses because of expensive machinery, but it reduces surface disruption and can be more economical for longer, deeper tunnels where cut and cover is impractical. Lifecycle costs vary, with cut and cover often requiring extensive restoration and traffic management, while tunnel boring offers faster completion and minimized impact on urban infrastructure.

Safety Considerations and Risk Management

Cut and cover construction exposes workers and the public to greater safety risks due to open trenches and potential ground collapses, requiring extensive shoring and traffic management. Tunnel boring machines (TBMs) reduce surface disruption and hazards but introduce risks such as equipment malfunctions, ventilation challenges, and confined space dangers that demand rigorous monitoring and emergency preparedness. Effective risk management in both methods hinges on comprehensive hazard assessments, continuous safety training, and adherence to stringent regulatory standards to minimize accidents and ensure project safety.

Case Studies: Global Examples of Each Method

Cut and cover construction was employed in the Boston Green Line Extension, effectively minimizing surface disruption despite its shallow depth constraints. Tunnel boring machines (TBMs) demonstrated success in the Channel Tunnel project between the UK and France, efficiently excavating through complex geology over 50 kilometers. The Singapore Downtown Line used a combination of both methods to optimize urban transit development, balancing cost and environmental impact.

Future Trends in Tunnel Construction Technologies

Cut and cover methods are increasingly integrated with advanced soil stabilization and robotic excavation technologies to minimize surface disruption and enhance construction speed. Tunnel boring machines (TBMs) are evolving with AI-driven navigation systems and real-time geotechnical monitoring, enabling safer and more efficient underground excavation in complex urban environments. Emerging trends highlight the growing adoption of hybrid techniques combining cut and cover with TBM innovations to optimize project costs and environmental impact.

Excavation Method

Cut and cover excavation involves shallow trench digging and surface restoration, while tunnel boring uses a tunnel boring machine (TBM) for deep, continuous underground excavation with minimal surface disruption.

Temporary Support Systems

Temporary support systems in cut and cover construction provide immediate soil stabilization unlike tunnel boring, which relies on the tunnel boring machine's continuous support to maintain excavation integrity.

Ground Settlement

Cut and cover excavation typically causes more extensive ground settlement compared to tunnel boring machines, which minimize surface disruption and reduce settlement risks.

Construction Footprint

Cut and cover construction results in a larger surface footprint causing more disruption to existing infrastructure and traffic compared to tunnel boring, which minimizes surface impact by excavating deep underground.

Shield Tunneling

Shield tunneling offers enhanced safety and precision compared to cut and cover methods, making it ideal for deep urban underground projects with minimal surface disruption.

Segmental Lining

Segmental lining in tunnel boring offers superior structural integrity and faster installation compared to cut and cover methods, minimizing surface disruption and enhancing long-term durability.

Surface Disruption

Cut and cover causes significant surface disruption due to excavation of large open trenches, while tunnel boring minimizes surface impact by tunneling deep underground.

Urban Constraints

Cut and cover construction demands extensive surface disruption and is often limited by urban traffic and existing infrastructure, whereas tunnel boring machines minimize surface impact and better accommodate dense urban constraints.

Muck Removal

Cut and cover excels in muck removal through direct excavation and dumping, while tunnel boring relies on conveyor belts or muck cars to efficiently transport debris from deep underground.

Waterproofing Systems

Cut and cover methods require extensive external waterproofing to prevent groundwater ingress during excavation, whereas tunnel boring machines (TBMs) enable the installation of pre-fabricated waterproof lining systems within the tunnel, offering enhanced long-term durability and reduced construction disruption.

cut and cover vs tunnel boring Infographic

njnir.com

njnir.com