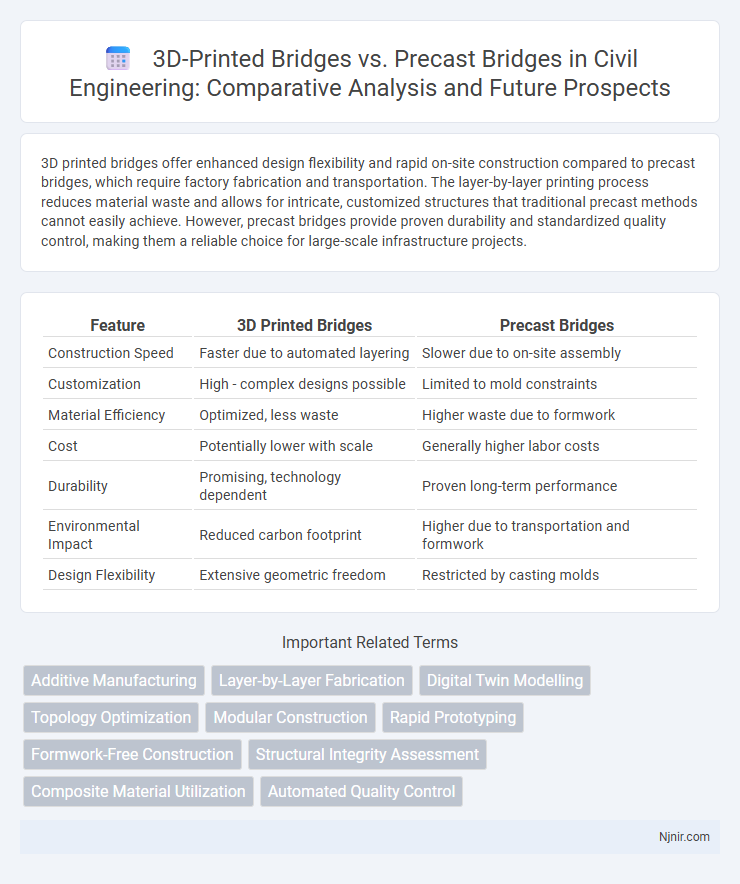

3D printed bridges offer enhanced design flexibility and rapid on-site construction compared to precast bridges, which require factory fabrication and transportation. The layer-by-layer printing process reduces material waste and allows for intricate, customized structures that traditional precast methods cannot easily achieve. However, precast bridges provide proven durability and standardized quality control, making them a reliable choice for large-scale infrastructure projects.

Table of Comparison

| Feature | 3D Printed Bridges | Precast Bridges |

|---|---|---|

| Construction Speed | Faster due to automated layering | Slower due to on-site assembly |

| Customization | High - complex designs possible | Limited to mold constraints |

| Material Efficiency | Optimized, less waste | Higher waste due to formwork |

| Cost | Potentially lower with scale | Generally higher labor costs |

| Durability | Promising, technology dependent | Proven long-term performance |

| Environmental Impact | Reduced carbon footprint | Higher due to transportation and formwork |

| Design Flexibility | Extensive geometric freedom | Restricted by casting molds |

Introduction to 3D Printed and Precast Bridges

3D printed bridges leverage additive manufacturing technology to create complex, customized structures with reduced material waste and faster construction times compared to traditional methods. Precast bridges consist of factory-made concrete components, offering high-quality control, durability, and rapid onsite assembly. Both technologies aim to improve efficiency and sustainability in modern infrastructure development.

Technological Overview: 3D Printing vs Precasting

3D printed bridges utilize additive manufacturing technology to create complex geometries layer by layer, enabling customization and material efficiency unmatched by traditional methods. Precast bridges rely on casting concrete components in controlled factory environments, ensuring consistent quality and faster on-site assembly but limited design flexibility. The key technological difference lies in 3D printing's capacity for rapid prototyping and intricate structural elements versus precasting's emphasis on standardized, mass-produced elements optimized for durability and scalability.

Material Innovations in Bridge Construction

Material innovations in bridge construction have revolutionized both 3D printed bridges and precast bridges, with 3D printing enabling the use of advanced composite materials and ultra-high-performance concrete tailored for complex geometries and enhanced durability. Precast bridges benefit from high-strength, fiber-reinforced concrete and corrosion-resistant reinforcement materials that improve load capacity and longevity while allowing for mass production and quality control. The integration of smart materials, such as self-healing concrete and sensors embedded during 3D printing, further distinguishes 3D printed bridges by offering real-time structural health monitoring and reduced maintenance costs.

Construction Speed and Efficiency Comparison

3D printed bridges significantly reduce construction time by enabling rapid layer-by-layer fabrication directly on-site, eliminating the need for formwork and minimizing labor demands compared to precast bridges that require off-site casting and lengthy curing processes. The digital design integration in 3D printing increases efficiency by allowing precise material placement and reducing waste, whereas precast bridges involve transportation and assembly stages that can delay project timelines. Overall, 3D printed bridges offer enhanced construction speed and streamlined workflows, making them a more efficient solution for infrastructure development.

Structural Performance and Load Capacity

3D printed bridges demonstrate enhanced structural performance through complex geometries optimized for stress distribution, resulting in improved load capacity compared to precast bridges. The additive manufacturing process allows for material reduction without compromising strength, yielding high strength-to-weight ratios in 3D printed components. Precast bridges rely on conventional reinforcement and uniform cross-sections, which may limit load capacity and adaptability to dynamic loads relative to the customizable nature of 3D printed structures.

Cost Analysis: 3D Printing vs Precasting

3D printed bridges offer significant cost savings through reduced labor expenses and material waste compared to precast bridges, which require extensive formwork and transportation logistics. The automation of 3D printing lowers production time and onsite assembly costs, while precast bridges involve higher expenses related to mold creation and heavy equipment. Long-term maintenance costs also tend to be lower for 3D printed bridges due to precise material deposition and improved structural consistency.

Sustainability and Environmental Impact

3D printed bridges significantly reduce material waste and carbon emissions by using precise additive manufacturing techniques, whereas precast bridges involve energy-intensive production and large transportation footprints. The use of sustainable materials in 3D printing, such as recycled plastics and geopolymer concrete, further enhances environmental benefits compared to traditional precast concrete. Lifecycle assessments show that 3D printed bridges have a lower overall environmental impact due to reduced resource consumption and on-site construction processes.

Design Flexibility and Customization Potential

3D printed bridges offer unparalleled design flexibility, enabling intricate geometries and complex structural forms that precast bridges cannot easily achieve due to manufacturing constraints. The customization potential of 3D printing allows for on-demand production tailored to specific site conditions and load requirements, reducing material waste and optimizing structural performance. In contrast, precast bridges rely on standardized molds, limiting adaptability and often necessitating multiple components for complex designs.

Case Studies: Real-World Applications

3D printed bridges, such as the MX3D bridge in Amsterdam, demonstrate rapid construction with complex geometries and reduced material waste compared to traditional precast bridges. Precast bridges, exemplified by the I-405 bridge project in California, offer proven durability and faster on-site assembly through modular components manufactured under controlled conditions. Both methods show potential in real-world applications, with 3D printing excelling in customization and sustainability, while precast bridges provide reliability and scalability for large infrastructure projects.

Future Trends in Bridge Building Technologies

3D printed bridges offer unprecedented design flexibility and rapid construction compared to traditional precast bridges, enabling complex geometries and material optimization that reduce costs and environmental impact. Emerging materials like advanced composites and high-performance concrete enhance the durability and sustainability of 3D printed structures, positioning them as a key innovation in future infrastructure development. Integration of AI-driven design and automated printing systems will further accelerate the adoption of 3D printing technology, transforming bridge building into a highly efficient, customizable process.

Additive Manufacturing

3D printed bridges using Additive Manufacturing offer customized designs, reduced material waste, and faster construction compared to traditional precast concrete bridges.

Layer-by-Layer Fabrication

3D printed bridges utilize layer-by-layer fabrication allowing for complex geometries and material efficiency, whereas precast bridges rely on traditional casting methods with limited design flexibility and longer production times.

Digital Twin Modelling

Digital Twin Modelling enhances 3D printed bridges by enabling real-time structural health monitoring and adaptive optimization, while precast bridges benefit from streamlined construction planning and predictive maintenance through digital replicas.

Topology Optimization

Topology optimization in 3D printed bridges enables precise material distribution for enhanced structural efficiency compared to the uniform material use in precast bridges.

Modular Construction

3D printed bridges enable faster, cost-effective modular construction with complex geometries and reduced material waste compared to traditional precast bridges, enhancing adaptability and sustainability in infrastructure projects.

Rapid Prototyping

Rapid prototyping with 3D printed bridges significantly accelerates design validation and customization processes compared to the standardized, time-intensive production of precast concrete bridges.

Formwork-Free Construction

3D printed bridges enable formwork-free construction by directly depositing material layer-by-layer, reducing labor and material costs compared to traditional precast bridges that require extensive formwork and molds.

Structural Integrity Assessment

3D printed bridges demonstrate comparable or superior structural integrity to precast bridges through enhanced material homogeneity and precise layer adhesion verified by nondestructive testing methods.

Composite Material Utilization

3D printed bridges enable precise composite material utilization by allowing optimized layer placement and tailored reinforcement, while precast bridges rely on standardized composite components with less material customization.

Automated Quality Control

Automated Quality Control in 3D printed bridges enables real-time defect detection and precise material consistency monitoring, surpassing traditional precast bridges' manual inspection limitations.

3D printed bridges vs precast bridges Infographic

njnir.com

njnir.com