Self-healing concrete significantly reduces maintenance costs and extends the lifespan of structures by autonomously sealing cracks without human intervention. Conventional repair methods require frequent inspections, labor-intensive processes, and often lead to structural downtime. The integration of self-healing materials enhances durability and sustainability in civil engineering projects compared to traditional repair techniques.

Table of Comparison

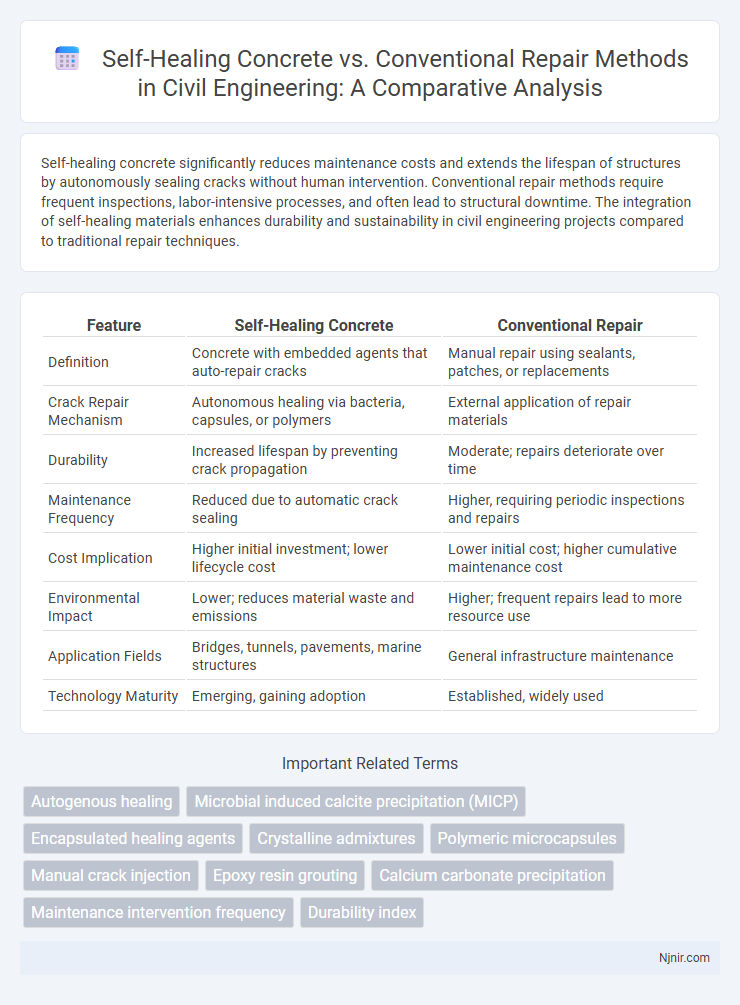

| Feature | Self-Healing Concrete | Conventional Repair |

|---|---|---|

| Definition | Concrete with embedded agents that auto-repair cracks | Manual repair using sealants, patches, or replacements |

| Crack Repair Mechanism | Autonomous healing via bacteria, capsules, or polymers | External application of repair materials |

| Durability | Increased lifespan by preventing crack propagation | Moderate; repairs deteriorate over time |

| Maintenance Frequency | Reduced due to automatic crack sealing | Higher, requiring periodic inspections and repairs |

| Cost Implication | Higher initial investment; lower lifecycle cost | Lower initial cost; higher cumulative maintenance cost |

| Environmental Impact | Lower; reduces material waste and emissions | Higher; frequent repairs lead to more resource use |

| Application Fields | Bridges, tunnels, pavements, marine structures | General infrastructure maintenance |

| Technology Maturity | Emerging, gaining adoption | Established, widely used |

Introduction to Self-Healing Concrete and Conventional Repair

Self-healing concrete incorporates microcapsules or bacteria that activate to seal cracks autonomously, significantly extending the material's lifespan and reducing maintenance costs compared to traditional methods. Conventional repair relies on manual interventions such as patching or epoxy injections, which often only address visible damage without preventing future deterioration. Integrating self-healing technology enhances structural durability and sustainability by minimizing the frequency and severity of repairs.

Mechanisms of Self-Healing in Concrete

Self-healing concrete incorporates mechanisms such as encapsulated healing agents, bacteria-induced mineral precipitation, and microcapsules that release repair materials when cracks form. These processes enable autonomous crack closure and restoration of structural integrity, contrasting with conventional repair methods that rely on external manual interventions like patching or epoxy injection. The internal healing mechanisms improve durability and extend the lifespan of concrete structures by preventing moisture ingress and corrosion associated with traditional repairs.

Traditional Concrete Repair Methods Overview

Traditional concrete repair methods typically involve mechanical removal of damaged sections, followed by patching with cementitious materials or epoxy injections to restore structural integrity. These techniques often require frequent maintenance due to issues like cracking, shrinkage, and lack of durability under environmental stress. Self-healing concrete, by contrast, incorporates bacteria or encapsulated agents that autonomously seal cracks, significantly reducing repair frequency and extending service life.

Comparative Cost Analysis: Self-Healing vs Conventional Repair

Self-healing concrete offers significant long-term cost savings compared to conventional repair methods by reducing maintenance frequency and minimizing structural downtime. Initial investment in self-healing materials is higher, but the extended lifespan and decreased labor expenses offset upfront costs. Conventional repairs incur recurrent expenses for crack monitoring, patching, and surface treatments, making them more costly over the structure's lifetime.

Durability and Longevity Comparison

Self-healing concrete significantly outperforms conventional repair methods in durability by autonomously sealing cracks, preventing moisture ingress and corrosion of reinforcement, which are primary causes of structural degradation. Conventional repair relies on external interventions that often fail to restore original strength and can degrade over time, leading to recurring maintenance. Studies indicate self-healing concrete extends the lifespan of structures by up to 50%, reducing lifecycle costs and enhancing long-term resilience against environmental stressors.

Environmental Impact and Sustainability

Self-healing concrete significantly reduces environmental impact by minimizing the need for frequent repairs and material replacements, lowering carbon emissions associated with construction activities. Unlike conventional repair methods, which often involve resource-intensive processes and generate substantial waste, self-healing concrete enhances sustainability through prolonged structural lifespan and reduced raw material consumption. Incorporating microcapsules or bacteria for crack repair optimizes resource efficiency, making self-healing concrete a more eco-friendly alternative in sustainable building practices.

Performance Under Different Environmental Conditions

Self-healing concrete demonstrates superior durability and longevity compared to conventional repair methods when exposed to various environmental conditions such as freeze-thaw cycles, moisture fluctuations, and chemical attacks. Its intrinsic ability to autonomously repair micro-cracks reduces permeability and prevents further deterioration, enhancing structural integrity in harsh climates. Conventional repairs often require repeated maintenance due to limited adaptability and vulnerability to environmental stressors, resulting in higher lifecycle costs and reduced performance.

Maintenance Requirements and Lifecycle Expectations

Self-healing concrete significantly reduces maintenance requirements by autonomously repairing micro-cracks, extending the structure's durability and minimizing the frequency of manual repairs compared to conventional concrete, which often necessitates costly and frequent interventions. Lifecycle expectations for self-healing concrete exceed those of traditional materials, with the ability to maintain structural integrity over decades by preventing crack propagation and corrosion-related damage. This innovative material provides a longer service life and lowers overall lifecycle costs, offering more sustainable and reliable infrastructure solutions.

Advances in Technology and Application Areas

Self-healing concrete utilizes advanced materials such as microcapsules, bacteria, or shape-memory polymers to autonomously repair cracks, significantly enhancing durability compared to conventional repair methods that require manual intervention and periodic maintenance. Innovations in biotechnology and nanotechnology have enabled these concrete systems to target microcracks early, reducing water permeability and extending the lifespan of infrastructure in sectors like transportation, water management, and marine construction. The adoption of self-healing concrete in smart cities and sustainable building projects demonstrates its potential to minimize repair costs and environmental impact, revolutionizing how structural integrity is maintained.

Future Prospects in Concrete Repair Solutions

Self-healing concrete offers significant future prospects in concrete repair solutions by reducing maintenance costs and extending structural lifespan through autonomous crack sealing using embedded microcapsules or bacteria. Unlike conventional repair methods that require manual intervention and frequent upkeep, self-healing technology enhances durability and sustainability in infrastructure projects. Advances in nanotechnology and bio-based healing agents are expected to further improve efficiency and application scope in large-scale construction.

Autogenous healing

Autogenous healing in self-healing concrete significantly reduces cracks and enhances durability compared to conventional repair methods by naturally sealing microcracks without external intervention.

Microbial induced calcite precipitation (MICP)

Microbial-induced calcite precipitation (MICP) in self-healing concrete enhances crack repair efficiency and durability compared to conventional repair methods by biologically precipitating calcite to fill cracks and restore structural integrity.

Encapsulated healing agents

Encapsulated healing agents in self-healing concrete significantly enhance durability and reduce maintenance costs compared to conventional repair methods by autonomously sealing cracks and preventing structural degradation.

Crystalline admixtures

Crystalline admixtures in self-healing concrete enhance crack sealing and durability by chemically reacting with moisture to form insoluble crystals, outperforming conventional repair methods in longevity and maintenance efficiency.

Polymeric microcapsules

Polymeric microcapsules in self-healing concrete release healing agents upon crack formation, significantly enhancing durability and reducing maintenance compared to conventional repair methods.

Manual crack injection

Self-healing concrete reduces the need for manual crack injection by autonomously sealing cracks, whereas conventional repair relies heavily on labor-intensive manual crack injection to restore structural integrity.

Epoxy resin grouting

Epoxy resin grouting in self-healing concrete offers superior crack sealing and durability compared to conventional repair methods by enhancing structural integrity and reducing maintenance costs.

Calcium carbonate precipitation

Self-healing concrete enhances durability by promoting Calcium carbonate precipitation that effectively seals cracks, whereas conventional repair methods often lack this autonomous regenerative capability.

Maintenance intervention frequency

Self-healing concrete significantly reduces maintenance intervention frequency compared to conventional repair methods by autonomously sealing cracks and preventing further deterioration.

Durability index

Self-healing concrete exhibits a significantly higher durability index, often exceeding 80%, compared to conventional repair methods which typically achieve durability indices below 60%.

self-healing concrete vs conventional repair Infographic

njnir.com

njnir.com