Fiber reinforcement offers enhanced corrosion resistance and improved crack control compared to traditional steel reinforcement, leading to increased durability in concrete structures. Unlike steel, fibers distribute uniformly throughout the concrete matrix, providing multidirectional strength and reducing the risk of localized failures. This makes fiber reinforcement especially advantageous in applications requiring lightweight, flexible, and long-lasting materials.

Table of Comparison

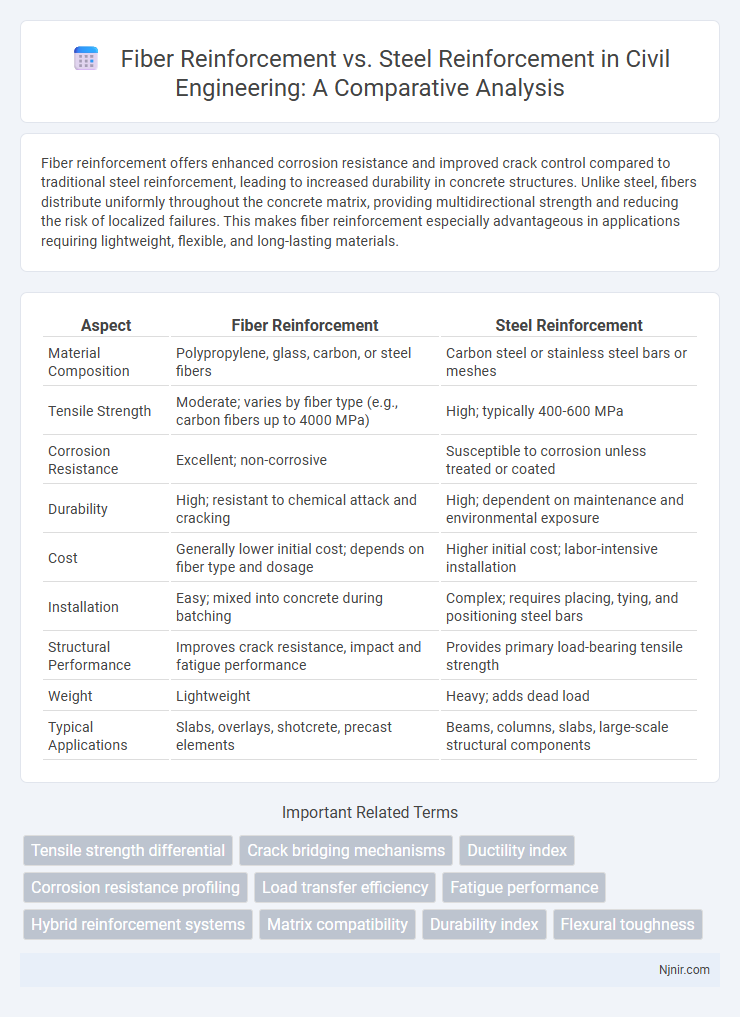

| Aspect | Fiber Reinforcement | Steel Reinforcement |

|---|---|---|

| Material Composition | Polypropylene, glass, carbon, or steel fibers | Carbon steel or stainless steel bars or meshes |

| Tensile Strength | Moderate; varies by fiber type (e.g., carbon fibers up to 4000 MPa) | High; typically 400-600 MPa |

| Corrosion Resistance | Excellent; non-corrosive | Susceptible to corrosion unless treated or coated |

| Durability | High; resistant to chemical attack and cracking | High; dependent on maintenance and environmental exposure |

| Cost | Generally lower initial cost; depends on fiber type and dosage | Higher initial cost; labor-intensive installation |

| Installation | Easy; mixed into concrete during batching | Complex; requires placing, tying, and positioning steel bars |

| Structural Performance | Improves crack resistance, impact and fatigue performance | Provides primary load-bearing tensile strength |

| Weight | Lightweight | Heavy; adds dead load |

| Typical Applications | Slabs, overlays, shotcrete, precast elements | Beams, columns, slabs, large-scale structural components |

Introduction to Reinforcement in Civil Engineering

Fiber reinforcement involves embedding synthetic or natural fibers into concrete to improve tensile strength and crack resistance, offering enhanced durability and flexibility. Steel reinforcement, consisting of rebar or welded wire mesh, provides high tensile capacity and structural support crucial for load-bearing elements in concrete structures. Both methods optimize concrete's performance in civil engineering by addressing its inherent brittleness and improving overall stability.

Overview of Fiber Reinforcement

Fiber reinforcement enhances concrete by incorporating discrete fibers such as glass, polypropylene, or steel into the mix, significantly improving tensile strength, crack resistance, and durability. Unlike traditional steel reinforcement, fiber reinforcement distributes stress more evenly throughout the material, reducing the likelihood of localized failure and increasing impact resistance. This method offers superior resistance to shrinkage and temperature variations, making it ideal for applications requiring long-term durability and reduced maintenance.

Overview of Steel Reinforcement

Steel reinforcement, commonly known as rebar, is widely used in concrete construction due to its high tensile strength and excellent bonding with concrete, enhancing structural durability and load-bearing capacity. It provides superior resistance to tension forces, making it essential for structural elements subjected to bending and shear stresses. Compared to fiber reinforcement, steel offers predictable mechanical performance and is crucial for maintaining concrete integrity in large-scale infrastructure projects.

Material Properties: Fiber vs Steel

Fiber reinforcement offers high tensile strength and excellent corrosion resistance, making it ideal for environments prone to chemical exposure and moisture. Steel reinforcement provides superior ductility and load-bearing capacity, ensuring robust structural integrity under heavy loads and dynamic stresses. The choice between fiber and steel depends on specific material properties such as tensile strength, elasticity modulus, corrosion resistance, and longevity requirements in construction applications.

Durability and Corrosion Resistance

Fiber reinforcement offers superior corrosion resistance compared to steel reinforcement, as synthetic or glass fibers do not rust or deteriorate when exposed to moisture and chemicals. This enhanced durability reduces maintenance costs and extends the service life of concrete structures, especially in aggressive environments such as marine or industrial areas. Steel reinforcement remains vulnerable to corrosion, which can lead to cracking, spalling, and overall structural weakening over time.

Structural Performance Comparison

Fiber reinforcement offers enhanced crack control and improved tensile strength compared to traditional steel reinforcement, resulting in better durability and reduced maintenance in concrete structures. Steel reinforcement provides superior load-bearing capacity and ductility, essential for handling heavy structural demands and dynamic forces. Combining both materials can optimize structural performance by leveraging the toughness of fibers and the strength of steel reinforcement.

Installation and Construction Techniques

Fiber reinforcement offers easier installation compared to steel reinforcement, as it eliminates the need for tying, cutting, and positioning steel bars, reducing labor time and costs on-site. Construction techniques with fiber reinforcement typically involve mixing fibers directly into the concrete or shotcrete, enabling faster placement and reducing the risk of steel corrosion and deformation during handling. Steel reinforcement requires precise layout and anchoring, with specialized equipment for bending and welding, often leading to longer installation schedules and increased complexity in construction management.

Cost Analysis and Economic Considerations

Fiber reinforcement typically offers a lower initial material cost compared to steel reinforcement, especially in applications requiring corrosion resistance and reduced maintenance expenses. Steel reinforcement incurs higher upfront costs due to raw material prices and labor-intensive installation but provides superior tensile strength and durability for heavy-load structures. Lifecycle cost analysis often favors fiber reinforcement in harsh environments, where its resistance to corrosion reduces long-term repair and replacement expenses, enhancing overall economic efficiency.

Sustainability and Environmental Impacts

Fiber reinforcement significantly reduces the environmental footprint compared to traditional steel reinforcement by lowering carbon emissions during production and transportation due to its lighter weight and longer lifespan. These materials, often made from recycled or natural fibers, offer enhanced durability and corrosion resistance, which minimizes maintenance needs and extends structural longevity. The decreased energy consumption and waste generation in fiber-reinforced composites contribute to more sustainable construction practices and reduced environmental impacts.

Applications and Case Studies

Fiber reinforcement offers enhanced crack resistance and corrosion durability, making it ideal for tunnel linings, bridge decks, and industrial flooring. Steel reinforcement remains the preferred choice for heavy-load structural elements such as beams, columns, and high-rise building frameworks due to its superior tensile strength. Case studies reveal that hybrid systems combining fiber and steel reinforcements optimize structural performance in seismic zones and marine environments by balancing flexibility and load-bearing capacity.

Tensile strength differential

Fiber reinforcement exhibits lower tensile strength compared to steel reinforcement, making steel the preferred choice for applications requiring superior tensile load resistance.

Crack bridging mechanisms

Fiber reinforcement enhances crack bridging by distributing stress across microcracks through numerous fibers, whereas steel reinforcement primarily controls crack widths by bearing tensile loads through large continuous bars.

Ductility index

Fiber reinforcement enhances the ductility index of concrete by improving deformation capacity and energy absorption compared to traditional steel reinforcement.

Corrosion resistance profiling

Fiber reinforcement offers superior corrosion resistance compared to steel reinforcement, significantly enhancing the durability and longevity of concrete structures in aggressive environments.

Load transfer efficiency

Fiber reinforcement offers superior load transfer efficiency through improved crack distribution and stress dispersion compared to traditional steel reinforcement.

Fatigue performance

Fiber reinforcement exhibits superior fatigue performance compared to steel reinforcement due to its higher resistance to crack propagation and better energy absorption capabilities under cyclic loading.

Hybrid reinforcement systems

Hybrid reinforcement systems combine fiber reinforcement's crack resistance with steel reinforcement's tensile strength to enhance concrete durability and structural performance.

Matrix compatibility

Fiber reinforcement offers superior matrix compatibility compared to steel reinforcement due to its chemical bonding properties and ability to distribute stress more evenly within the composite material.

Durability index

Fiber reinforcement exhibits a higher durability index than steel reinforcement due to its enhanced resistance to corrosion and fatigue under harsh environmental conditions.

Flexural toughness

Fiber reinforcement significantly enhances flexural toughness by improving crack resistance and energy absorption compared to traditional steel reinforcement.

fiber reinforcement vs steel reinforcement Infographic

njnir.com

njnir.com