Fly ash and slag cement both serve as supplementary cementitious materials that enhance concrete durability and strength. Fly ash, a byproduct of coal combustion, improves workability and reduces permeability, while slag cement, derived from granulated blast furnace slag, offers superior sulfate resistance and higher long-term strength. Selecting between fly ash and slag cement depends on project-specific requirements such as exposure conditions, desired setting time, and environmental considerations.

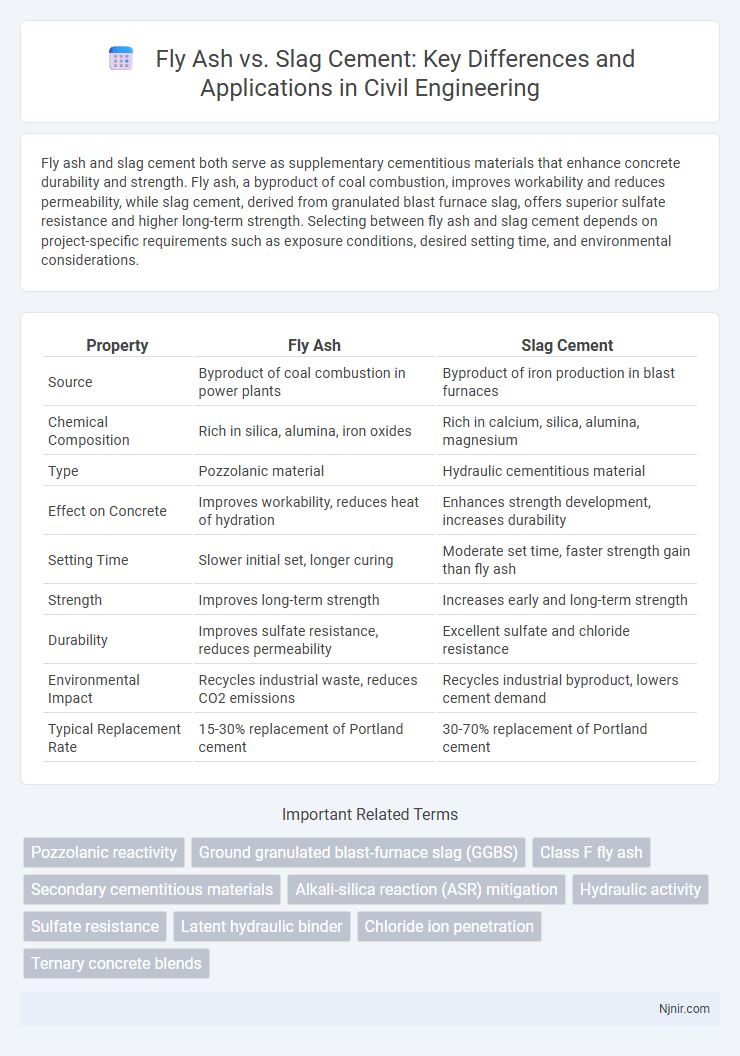

Table of Comparison

| Property | Fly Ash | Slag Cement |

|---|---|---|

| Source | Byproduct of coal combustion in power plants | Byproduct of iron production in blast furnaces |

| Chemical Composition | Rich in silica, alumina, iron oxides | Rich in calcium, silica, alumina, magnesium |

| Type | Pozzolanic material | Hydraulic cementitious material |

| Effect on Concrete | Improves workability, reduces heat of hydration | Enhances strength development, increases durability |

| Setting Time | Slower initial set, longer curing | Moderate set time, faster strength gain than fly ash |

| Strength | Improves long-term strength | Increases early and long-term strength |

| Durability | Improves sulfate resistance, reduces permeability | Excellent sulfate and chloride resistance |

| Environmental Impact | Recycles industrial waste, reduces CO2 emissions | Recycles industrial byproduct, lowers cement demand |

| Typical Replacement Rate | 15-30% replacement of Portland cement | 30-70% replacement of Portland cement |

Introduction to Fly Ash and Slag Cement

Fly ash is a byproduct of coal combustion in power plants, commonly used as a supplementary cementitious material to enhance concrete durability and reduce environmental impact. Slag cement, also known as ground granulated blast-furnace slag (GGBFS), is derived from the iron-making process and is valued for its ability to improve concrete strength and resistance to chemical attack. Both materials contribute to sustainable construction by recycling industrial waste and lowering the carbon footprint of traditional Portland cement.

Chemical Composition Differences

Fly ash primarily contains high amounts of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), making it a pozzolanic material, whereas slag cement is rich in calcium oxide (CaO), along with significant magnesium oxide (MgO) and alumina content. The higher calcium content in slag cement contributes to its latent hydraulic properties, enabling it to hydrate and gain strength independently. Fly ash's lower calcium levels result in slower strength development, but it enhances durability and sulfate resistance when used in concrete.

Production Processes Compared

Fly ash is a byproduct of coal combustion in power plants, collected from the smokestacks' particulate filters, whereas slag cement originates from the quenching of molten blast furnace slag in water, forming granulated slag that is then ground into a fine powder. The production of fly ash involves capturing fine particles from coal combustion gases, making it a supplementary cementitious material rich in silica and alumina. In contrast, slag cement production depends on the controlled cooling of slag, resulting in a hydraulic material with latent cementitious properties activated by mixing with water and Portland cement.

Physical Properties and Performance

Fly ash and slag cement exhibit distinct physical properties influencing their performance in concrete. Fly ash particles are spherical and finer, improving workability and reducing water demand, while slag cement has angular particles that enhance strength development due to latent hydraulic properties. Performance-wise, slag cement provides higher early strength and better sulfate resistance, whereas fly ash improves long-term durability and reduces permeability, making each suitable for specific structural requirements.

Applications in Concrete Mixes

Fly ash enhances concrete durability and workability, making it ideal for structural elements, pavements, and mass concrete applications. Slag cement improves sulfate resistance and reduces permeability, suited for marine structures, wastewater treatment plants, and high-strength concrete mixes. Combining both materials optimizes performance by leveraging the pozzolanic properties of fly ash and the latent hydraulic properties of slag cement.

Environmental Impact Assessment

Fly ash and slag cement both significantly reduce the carbon footprint of concrete by replacing a portion of Portland cement, which is a major source of CO2 emissions in construction. Fly ash, a byproduct of coal combustion, helps divert industrial waste from landfills, while slag cement, derived from iron blast furnace slag, promotes the reuse of metallurgical byproducts. Lifecycle assessments reveal that slag cement often offers greater reductions in embodied energy and greenhouse gas emissions compared to fly ash, enhancing sustainability in concrete production.

Strength and Durability Characteristics

Fly ash enhances concrete strength over time by promoting pozzolanic reactions that refine pore structure and increase density, leading to improved long-term durability and resistance to sulfate attack. Slag cement significantly improves early and ultimate compressive strength by accelerating hydration and forming stable calcium silicate hydrates, thus providing superior resistance to chloride penetration and reducing permeability. Both materials contribute to improved resistance against alkali-silica reaction, with slag cement offering slightly better performance in aggressive chemical environments due to its dense microstructure.

Workability and Setting Time

Fly ash enhances workability by improving concrete's flow and reducing water demand due to its spherical particle shape, which acts as a lubricant in the mix. Slag cement also contributes to improved workability but generally results in a slightly faster setting time compared to fly ash, which tends to retard the setting process, making it ideal for hot weather concreting. The choice between fly ash and slag cement significantly influences the balance between workability and setting time, impacting overall concrete performance and application suitability.

Cost Analysis and Availability

Fly ash generally offers a lower cost compared to slag cement due to its widespread availability as a byproduct of coal combustion in power plants, making it more accessible in regions with extensive coal-fired energy production. Slag cement, derived from ground granulated blast furnace slag, often incurs higher costs linked to limited production facilities and transportation from steel manufacturing locations. Availability of fly ash is region-dependent; areas with declining coal plants face supply challenges, whereas slag cement maintains steadier but less abundant supply constrained by steel industry output.

Industry Standards and Codes

Fly ash and slag cement are both supplementary cementitious materials classified under ASTM C618 and ASTM C989 standards, respectively, which specify chemical and physical requirements for their use in concrete. Fly ash is commonly used in compliance with ASTM C618 Class F or Class C designations, while slag cement adheres to ASTM C989 Grade 80, 100, or 120, indicating strength activity indices. Both materials are recognized by ACI and relevant building codes like the International Building Code (IBC) for enhancing concrete durability, sustainability, and performance in structural applications.

Pozzolanic reactivity

Fly ash exhibits higher pozzolanic reactivity due to its fine particle size and amorphous silica content, whereas slag cement offers slower but sustained pozzolanic reactions with greater calcium content enhancing strength development.

Ground granulated blast-furnace slag (GGBS)

Ground granulated blast-furnace slag (GGBS) significantly enhances concrete durability and reduces carbon footprint compared to fly ash by providing superior cementitious properties and resistance to sulfate attack.

Class F fly ash

Class F fly ash, with its low calcium content and pozzolanic properties, enhances the durability and strength of concrete when used as a supplementary cementitious material compared to slag cement, which primarily offers latent hydraulic properties.

Secondary cementitious materials

Fly ash and slag cement are secondary cementitious materials that improve concrete durability, reduce permeability, and lower carbon emissions by partially replacing Portland cement in concrete mixes.

Alkali-silica reaction (ASR) mitigation

Fly ash and slag cement both effectively mitigate Alkali-Silica Reaction (ASR), with fly ash reducing alkali content and silica reactivity, while slag cement lowers permeability and calcium hydroxide, enhancing concrete durability.

Hydraulic activity

Fly ash exhibits lower hydraulic activity compared to slag cement, which demonstrates higher calcium silicate hydrate formation resulting in superior early strength development.

Sulfate resistance

Slag cement generally offers superior sulfate resistance compared to fly ash, effectively minimizing sulfate-induced expansion and concrete degradation in harsh environments.

Latent hydraulic binder

Fly ash and slag cement both serve as latent hydraulic binders by reacting with calcium hydroxide in the presence of water to form cementitious compounds that enhance concrete durability and strength.

Chloride ion penetration

Fly ash and slag cement both reduce chloride ion penetration in concrete, with slag cement typically providing superior resistance due to its denser microstructure and lower permeability.

Ternary concrete blends

Ternary concrete blends combining fly ash, slag cement, and Portland cement enhance durability, reduce permeability, and improve long-term strength compared to binary or single supplementary cementitious material mixtures.

fly ash vs slag cement Infographic

njnir.com

njnir.com