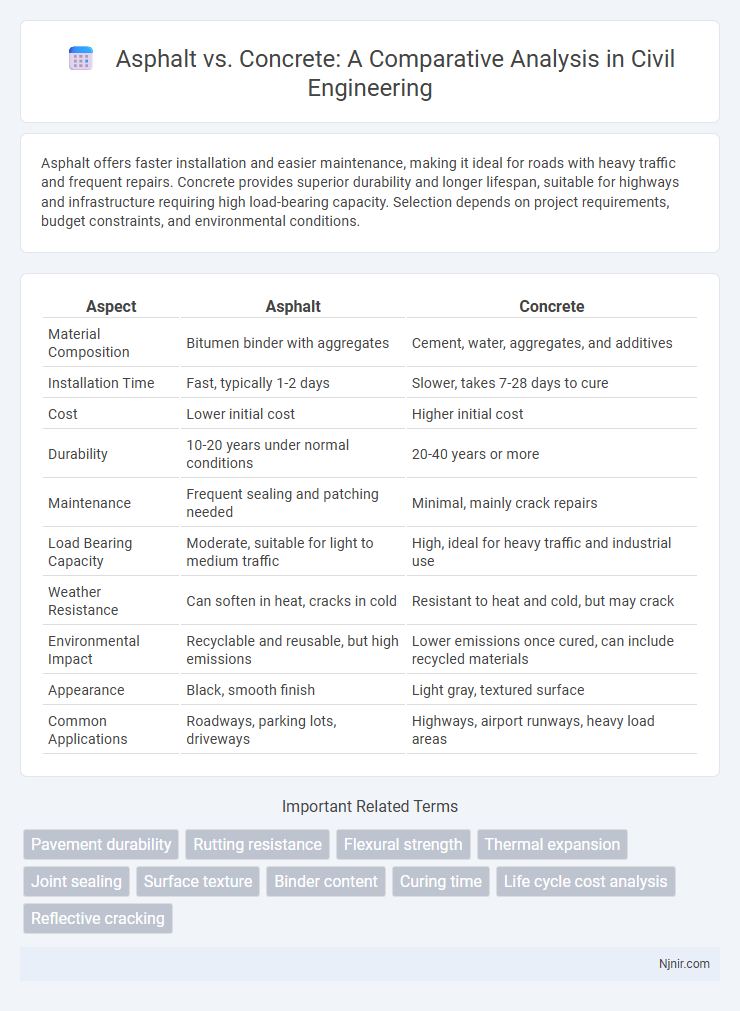

Asphalt offers faster installation and easier maintenance, making it ideal for roads with heavy traffic and frequent repairs. Concrete provides superior durability and longer lifespan, suitable for highways and infrastructure requiring high load-bearing capacity. Selection depends on project requirements, budget constraints, and environmental conditions.

Table of Comparison

| Aspect | Asphalt | Concrete |

|---|---|---|

| Material Composition | Bitumen binder with aggregates | Cement, water, aggregates, and additives |

| Installation Time | Fast, typically 1-2 days | Slower, takes 7-28 days to cure |

| Cost | Lower initial cost | Higher initial cost |

| Durability | 10-20 years under normal conditions | 20-40 years or more |

| Maintenance | Frequent sealing and patching needed | Minimal, mainly crack repairs |

| Load Bearing Capacity | Moderate, suitable for light to medium traffic | High, ideal for heavy traffic and industrial use |

| Weather Resistance | Can soften in heat, cracks in cold | Resistant to heat and cold, but may crack |

| Environmental Impact | Recyclable and reusable, but high emissions | Lower emissions once cured, can include recycled materials |

| Appearance | Black, smooth finish | Light gray, textured surface |

| Common Applications | Roadways, parking lots, driveways | Highways, airport runways, heavy load areas |

Material Composition: Asphalt vs Concrete

Asphalt consists mainly of aggregates and bitumen, a petroleum-based binder that provides flexibility and waterproofing, making it ideal for road surfaces subject to temperature fluctuations. Concrete comprises cement, water, sand, and gravel, forming a rigid and durable material known for its high compressive strength and longevity in heavy-load applications. The different material compositions directly affect performance characteristics, maintenance requirements, and lifecycle costs in infrastructure projects.

Installation Process Comparison

Asphalt installation requires a shorter curing time, typically 24 to 48 hours, allowing for quicker project completion, while concrete demands a curing period of 7 to 28 days to achieve full strength. Asphalt paving involves a layered approach starting with a base of crushed stone, followed by hot asphalt mix applied with a paving machine and compacted with a roller, whereas concrete installation requires pouring a slurry mixture into forms, leveling, and finishing before curing. The complexity and labor intensity of concrete installation often result in higher initial costs and longer downtime compared to the faster, more straightforward asphalt process.

Cost Analysis: Initial and Long-term

Asphalt typically offers lower initial installation costs, averaging $2 to $5 per square foot, compared to concrete's $4 to $10 per square foot, making it a budget-friendly option for short-term projects. Long-term maintenance expenses are generally higher for asphalt due to its susceptibility to cracking and potholes, requiring periodic sealcoating and repairs every 3 to 5 years. Concrete, despite its higher upfront price, provides greater durability and lower long-term maintenance, often lasting 30 to 40 years with minimal upkeep, resulting in a more cost-effective solution over time for high-traffic areas.

Durability and Lifespan Differences

Concrete typically outlasts asphalt with a lifespan of 30 to 40 years compared to asphalt's 15 to 20 years, due to its rigid structure and resistance to weathering. Asphalt offers more flexibility, allowing it to handle temperature fluctuations and minor ground movements better, but it requires more frequent maintenance and repairs. The durability of concrete makes it ideal for high-traffic areas, while asphalt's cost-effectiveness suits residential driveways and roads with lighter use.

Maintenance Requirements and Frequency

Asphalt requires more frequent maintenance than concrete, typically needing sealcoating every 2-3 years to prevent cracks and surface deterioration. Concrete surfaces demand less routine upkeep but often require joint resealing and occasional crack repairs approximately every 5-10 years. Both materials' maintenance costs and frequency depend on traffic loads, climate conditions, and installation quality.

Performance Under Various Weather Conditions

Asphalt demonstrates superior flexibility, making it more resistant to cracking in cold climates, while concrete excels in hot weather due to its high thermal mass that reduces surface temperature. Concrete surfaces offer better durability under prolonged heat and exposure to UV radiation, resisting rutting and deformation. Asphalt's permeability allows faster melting of ice and snow, enhancing safety in winter conditions and minimizing maintenance costs.

Environmental Impact Assessment

Asphalt and concrete differ significantly in their environmental impact assessment, with asphalt generally exhibiting lower embodied energy and emitting fewer greenhouse gases during production. Concrete's higher carbon footprint stems largely from cement manufacturing, which releases substantial CO2, although concrete offers longer durability and recyclability benefits. Evaluations also highlight asphalt's potential for urban heat island effect reduction when using lighter-colored or permeable mixtures, influencing environmental sustainability decisions in infrastructure projects.

Aesthetic Options and Customization

Asphalt offers a sleek, dark finish that can be enhanced with stamped patterns or colored sealants for varied aesthetics. Concrete provides extensive customization with options like decorative stamping, exposed aggregate, staining, and dyeing to achieve unique textures and vibrant colors. The choice between asphalt and concrete depends on the desired visual appeal and design flexibility for surfaces such as driveways, patios, and walkways.

Typical Applications in Civil Engineering Projects

Asphalt is commonly used for flexible pavements such as highways, airport runways, and parking lots due to its quick installation and ease of repair. Concrete is preferred in heavy-duty applications like airport taxiways, bridge decks, and industrial floors because of its high durability and load-bearing capacity. Both materials are selected based on project-specific factors including traffic load, environmental conditions, and maintenance requirements.

Future Trends and Innovations in Paving Materials

Future trends in paving materials emphasize sustainability and durability, with innovations like eco-friendly asphalt mixtures incorporating recycled plastics and bio-based additives to reduce carbon footprints. Concrete advancements include ultra-high-performance concrete (UHPC) and self-healing technologies that extend pavement lifespan and minimize maintenance costs. Smart pavements embedded with sensors for real-time monitoring of structural health and traffic conditions represent a growing shift toward intelligent infrastructure in both asphalt and concrete applications.

Pavement durability

Concrete pavement typically offers greater durability than asphalt due to its higher resistance to heavy loads and longer lifespan, making it a preferred choice for high-traffic areas.

Rutting resistance

Concrete exhibits superior rutting resistance compared to asphalt due to its higher stiffness and durability under heavy traffic loads.

Flexural strength

Concrete exhibits higher flexural strength compared to asphalt, making it more suitable for load-bearing applications requiring resistance to bending and cracking.

Thermal expansion

Asphalt exhibits greater thermal expansion than concrete, causing more significant surface deformation under temperature fluctuations.

Joint sealing

Effective joint sealing in asphalt prevents water infiltration and extends pavement lifespan, while concrete joint sealing requires specialized materials to accommodate expansion and contraction.

Surface texture

Asphalt provides a smoother surface texture ideal for reducing tire noise and improving skid resistance, while concrete offers a rougher texture that enhances durability and load-bearing capabilities.

Binder content

Asphalt contains 5-10% binder composed of bitumen, while concrete uses about 10-15% binder primarily in the form of cement paste.

Curing time

Concrete requires 7 to 28 days to fully cure, whereas asphalt typically cures within 24 to 48 hours, enabling faster usability.

Life cycle cost analysis

Asphalt typically offers lower initial costs but higher maintenance expenses over time, while concrete entails higher upfront costs with greater durability and reduced life cycle costs in long-term pavement cost analysis.

Reflective cracking

Asphalt surfaces generally exhibit greater resistance to reflective cracking compared to rigid concrete pavements, which are more susceptible due to their rigidity and jointed structure.

Asphalt vs Concrete Infographic

njnir.com

njnir.com