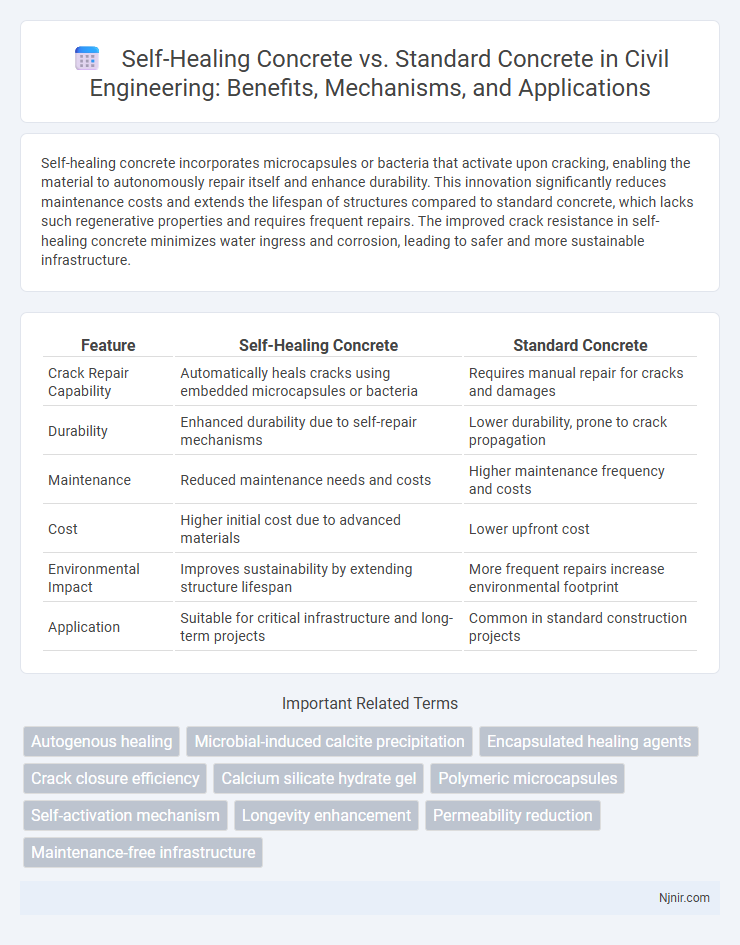

Self-healing concrete incorporates microcapsules or bacteria that activate upon cracking, enabling the material to autonomously repair itself and enhance durability. This innovation significantly reduces maintenance costs and extends the lifespan of structures compared to standard concrete, which lacks such regenerative properties and requires frequent repairs. The improved crack resistance in self-healing concrete minimizes water ingress and corrosion, leading to safer and more sustainable infrastructure.

Table of Comparison

| Feature | Self-Healing Concrete | Standard Concrete |

|---|---|---|

| Crack Repair Capability | Automatically heals cracks using embedded microcapsules or bacteria | Requires manual repair for cracks and damages |

| Durability | Enhanced durability due to self-repair mechanisms | Lower durability, prone to crack propagation |

| Maintenance | Reduced maintenance needs and costs | Higher maintenance frequency and costs |

| Cost | Higher initial cost due to advanced materials | Lower upfront cost |

| Environmental Impact | Improves sustainability by extending structure lifespan | More frequent repairs increase environmental footprint |

| Application | Suitable for critical infrastructure and long-term projects | Common in standard construction projects |

Introduction to Self-Healing and Standard Concrete

Self-healing concrete incorporates microcapsules or bacteria that activate upon cracking, autonomously sealing fractures and enhancing durability, while standard concrete lacks this self-repair capability, relying solely on external maintenance. This innovative technology significantly extends the lifespan of infrastructure by reducing permeability and preventing corrosion, addressing common degradation issues in traditional concrete structures. By integrating self-healing mechanisms, modern concrete offers increased resilience and sustainability compared to conventional concrete mixes.

Composition and Material Science

Self-healing concrete incorporates microcapsules or bacterial spores within its matrix, enabling automatic crack repair through chemical reactions or biological processes, unlike standard concrete that lacks such features. The composition includes specialized polymers, calcium carbonate-producing bacteria, or healing agents encapsulated in silica gel, enhancing durability and reducing maintenance costs. Material science advancements focus on optimizing these agents' integration to maintain mechanical properties while promoting autonomous crack closure.

Mechanisms of Crack Repair

Self-healing concrete utilizes embedded microcapsules or bacteria that produce calcium carbonate to autonomously seal cracks, enhancing durability and reducing maintenance. Standard concrete relies on passive mechanical properties and external repair methods, which can be labor-intensive and costly. The intrinsic crack repair mechanism in self-healing concrete significantly prolongs structural lifespan by minimizing crack propagation and water ingress.

Durability and Lifespan Comparison

Self-healing concrete significantly outperforms standard concrete in durability by autonomously repairing microcracks through embedded healing agents like bacteria or polymers, which prevents water ingress and reduces corrosion of reinforcement steel. This innovative material extends the lifespan of structures by maintaining structural integrity and minimizing maintenance costs, often doubling the service life compared to traditional concrete. Studies indicate self-healing concrete can improve durability by up to 50%, making it ideal for infrastructure exposed to harsh environmental conditions.

Cost Analysis: Initial and Long-Term

Self-healing concrete typically incurs higher initial costs due to advanced materials like microcapsules or bacteria-based agents but offers significant long-term savings by reducing repair and maintenance expenses. Standard concrete involves lower upfront investment but often leads to increased lifecycle costs from frequent crack repairs and durability issues. Cost analysis reveals that while self-healing concrete demands more capital initially, it enhances structural longevity and decreases overall expenditure over time.

Environmental Impact and Sustainability

Self-healing concrete significantly reduces environmental impact by minimizing the need for repairs and extending the lifespan of structures, thereby lowering CO2 emissions associated with production and maintenance compared to standard concrete. It incorporates bacteria or chemical agents that autonomously fill cracks, reducing material waste and resource consumption over time. This innovation promotes sustainability by conserving natural resources and decreasing landfill waste from demolished concrete debris.

Performance in Extreme Conditions

Self-healing concrete significantly outperforms standard concrete in extreme conditions by autonomously repairing micro-cracks caused by temperature fluctuations, freeze-thaw cycles, and chemical exposure, thereby extending structural durability. Its embedded healing agents activate upon crack formation, ensuring sustained integrity and reducing maintenance costs. Standard concrete lacks this adaptive capability, leading to accelerated deterioration and reduced lifespan under harsh environments.

Maintenance and Repair Requirements

Self-healing concrete significantly reduces maintenance and repair requirements by autonomously sealing cracks using embedded bacteria or microcapsules, preventing water ingress and further deterioration. Standard concrete typically requires frequent inspections and costly repairs due to its inability to self-repair, leading to accelerated damage from environmental exposure. This innovation enhances structural durability and minimizes lifecycle costs, making self-healing concrete a superior choice for long-term infrastructure resilience.

Real-World Applications and Case Studies

Self-healing concrete, embedded with microcapsules or bacteria that activate upon crack formation, has been successfully applied in infrastructure projects such as highway pavements, bridge decks, and marine structures, significantly reducing maintenance costs and extending service life. Case studies from the Netherlands demonstrate improved durability and reduced permeability in canal walls, while airports in China utilize this technology to minimize downtime due to concrete degradation. In contrast, standard concrete requires frequent repairs and monitoring, leading to higher lifecycle expenses and potential structural risks in demanding environmental conditions.

Future Prospects and Industry Trends

Self-healing concrete, embedded with microcapsules or bacteria, promises extended infrastructure lifespan by autonomously repairing cracks, reducing maintenance costs and environmental impact. Industry trends indicate increasing adoption driven by smart city initiatives and sustainability goals, with ongoing research improving material efficiency and scalability. Future prospects highlight integration with IoT sensors for real-time structural health monitoring, positioning self-healing concrete as a transformative innovation in construction technology.

Autogenous healing

Self-healing concrete enhances durability by autonomously sealing cracks through autogenous healing mechanisms, unlike standard concrete that relies on external repairs.

Microbial-induced calcite precipitation

Microbial-induced calcite precipitation enhances self-healing concrete by enabling autonomous crack repair through bacteria-induced mineral deposition, significantly improving durability compared to standard concrete.

Encapsulated healing agents

Encapsulated healing agents in self-healing concrete autonomously repair microcracks, significantly enhancing durability and lifespan compared to standard concrete without such agents.

Crack closure efficiency

Self-healing concrete demonstrates up to 90% crack closure efficiency compared to standard concrete's limited natural healing capacity of less than 25%.

Calcium silicate hydrate gel

Self-healing concrete enhances durability by utilizing calcium silicate hydrate gel to autonomously seal cracks, unlike standard concrete which lacks this regenerative capability.

Polymeric microcapsules

Polymeric microcapsules embedded in self-healing concrete release healing agents upon cracking, significantly enhancing durability and reducing maintenance compared to standard concrete.

Self-activation mechanism

Self-healing concrete utilizes a self-activation mechanism involving embedded microcapsules or bacteria that react with moisture to initiate crack repair, enhancing durability compared to standard concrete.

Longevity enhancement

Self-healing concrete significantly enhances longevity by autonomously repairing cracks, reducing maintenance costs and extending structural lifespan compared to standard concrete.

Permeability reduction

Self-healing concrete significantly reduces permeability by autonomously sealing microcracks, enhancing durability compared to standard concrete's higher susceptibility to water ingress.

Maintenance-free infrastructure

Self-healing concrete reduces maintenance costs and extends infrastructure lifespan by automatically repairing cracks, unlike standard concrete which requires frequent manual interventions.

Self-healing concrete vs Standard concrete Infographic

njnir.com

njnir.com