FRP reinforcement offers superior corrosion resistance compared to traditional steel reinforcement, enhancing durability in aggressive environments. Its lightweight properties reduce transportation and handling costs, while maintaining high tensile strength for structural integrity. Unlike steel, FRP does not rust, making it ideal for infrastructure exposed to moisture and chemicals.

Table of Comparison

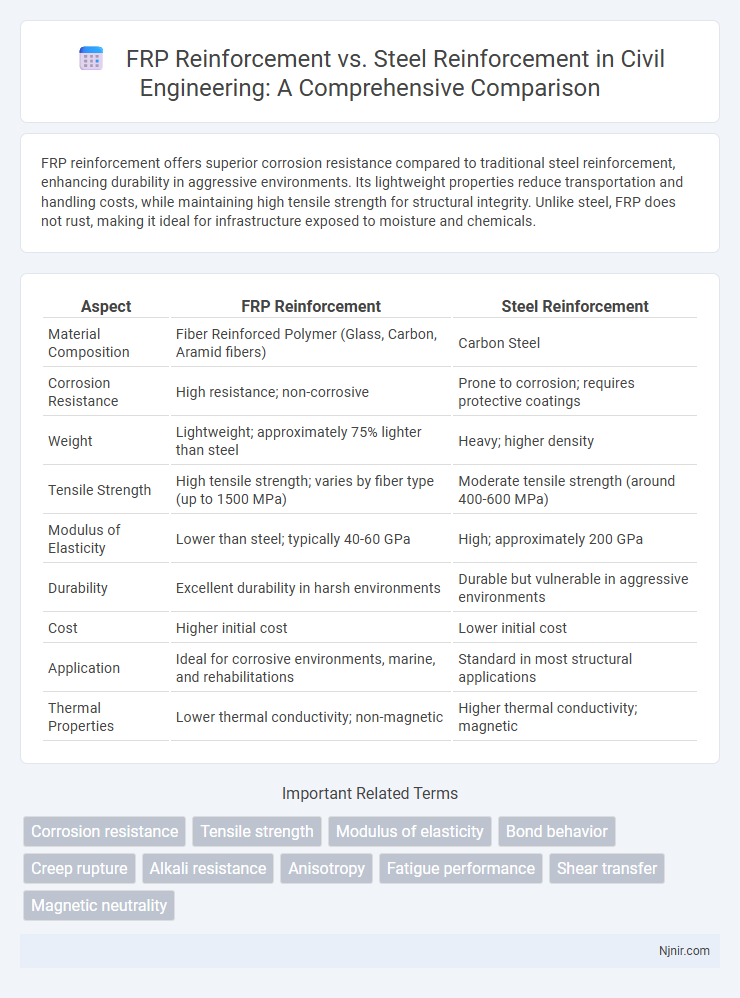

| Aspect | FRP Reinforcement | Steel Reinforcement |

|---|---|---|

| Material Composition | Fiber Reinforced Polymer (Glass, Carbon, Aramid fibers) | Carbon Steel |

| Corrosion Resistance | High resistance; non-corrosive | Prone to corrosion; requires protective coatings |

| Weight | Lightweight; approximately 75% lighter than steel | Heavy; higher density |

| Tensile Strength | High tensile strength; varies by fiber type (up to 1500 MPa) | Moderate tensile strength (around 400-600 MPa) |

| Modulus of Elasticity | Lower than steel; typically 40-60 GPa | High; approximately 200 GPa |

| Durability | Excellent durability in harsh environments | Durable but vulnerable in aggressive environments |

| Cost | Higher initial cost | Lower initial cost |

| Application | Ideal for corrosive environments, marine, and rehabilitations | Standard in most structural applications |

| Thermal Properties | Lower thermal conductivity; non-magnetic | Higher thermal conductivity; magnetic |

Introduction to FRP and Steel Reinforcement

Fiber Reinforced Polymer (FRP) reinforcement, composed of high-strength fibers embedded in a polymer matrix, offers corrosion resistance, lightweight properties, and high tensile strength compared to traditional steel reinforcement. Steel reinforcement, characterized by its ductility, proven structural performance, and ease of availability, remains the most widely used material in concrete construction for enhancing tensile capacity. The choice between FRP and steel reinforcement impacts durability, maintenance costs, and structural behavior, making understanding their fundamental properties essential in modern engineering applications.

Material Properties and Composition

FRP reinforcement is composed of high-strength fibers such as carbon, glass, or aramid embedded in a polymer resin matrix, offering superior corrosion resistance compared to traditional steel reinforcement. Its lightweight nature and high tensile strength result from the synthetic composite materials, while steel is characterized by its ductility, high modulus of elasticity, and susceptibility to rust and corrosion. Unlike steel, FRP materials exhibit non-metallic properties, including electromagnetic neutrality and resistance to chemical degradation, making them ideal for environments where durability and low maintenance are critical.

Strength and Durability Comparison

Fiber Reinforced Polymer (FRP) reinforcement offers superior corrosion resistance compared to traditional steel reinforcement, significantly enhancing durability in aggressive environments such as marine or chemical-exposed structures. While steel reinforcement exhibits high tensile strength, FRP materials like carbon and glass fibers provide comparable or greater strength-to-weight ratios, reducing structural weight without compromising load-bearing capacity. The reduced risk of corrosion and subsequent maintenance costs make FRP reinforcement a preferred choice for longevity and structural integrity in harsh conditions.

Corrosion Resistance

FRP reinforcement offers superior corrosion resistance compared to steel reinforcement, making it ideal for structures exposed to harsh environments such as marine or chemical settings. Unlike steel, which is prone to rust and degradation when exposed to moisture and chlorides, FRP materials like glass fiber or carbon fiber remain unaffected, ensuring longer service life and reduced maintenance costs. This corrosion resistance significantly enhances durability and structural integrity in applications vulnerable to aggressive environmental conditions.

Installation Process and Ease

FRP reinforcement offers significant advantages over steel reinforcement in terms of installation, as its lightweight nature simplifies handling and reduces labor costs on-site. Unlike steel, FRP does not require special equipment for cutting or bending, enabling faster placement and minimizing installation time. Furthermore, FRP's corrosion resistance eliminates the need for protective coatings or treatments, enhancing overall ease during the construction process.

Cost Analysis and Lifecycle Considerations

FRP reinforcement offers higher initial material costs compared to traditional steel reinforcement but significantly reduces maintenance expenses due to its corrosion resistance and longer lifespan. Lifecycle cost analysis reveals that FRP's durability in aggressive environments lowers overall expenses by minimizing repair frequency and extending service life. Steel reinforcement benefits from lower upfront costs but incurs higher long-term costs from corrosion protection, maintenance, and potential structural repairs.

Design Codes and Standards

FRP reinforcement is governed by emerging design codes such as ACI 440.1R and accepted in standards like ISO 10406, emphasizing corrosion resistance and lightweight benefits, while steel reinforcement follows well-established codes including ACI 318 and Eurocode 2, which focus on ductility and yield strength parameters. Design standards for FRP require different stress-strain relationships and consider factors like environmental durability and anisotropy, compared to the isotropic behavior and plastic deformation characteristics covered in steel reinforcement codes. The selection between FRP and steel reinforcement depends on project-specific criteria, with evolving standards continuously integrating FRP to extend design possibilities in civil engineering structures.

Environmental Impact and Sustainability

FRP reinforcement significantly reduces environmental impact due to its corrosion resistance, which extends the lifespan of concrete structures and minimizes maintenance-related emissions. Unlike steel reinforcement, FRP manufacturing consumes less energy and emits fewer greenhouse gases, contributing to improved sustainability in construction projects. The lightweight nature of FRP also lowers transportation fuel consumption, further decreasing the carbon footprint compared to traditional steel reinforcement.

Typical Applications in Civil Engineering

FRP reinforcement is widely utilized in bridge decks, marine structures, and seismic retrofitting due to its corrosion resistance and lightweight properties, making it ideal for harsh environments. Steel reinforcement remains dominant in typical reinforced concrete structures like buildings, highways, and tunnels because of its high tensile strength and well-established construction practices. Engineers select FRP for applications requiring non-magnetic or electrically non-conductive materials, while steel is favored where ductility and proven reliability are critical.

Future Trends in Reinforcement Technology

Future trends in reinforcement technology emphasize the growing adoption of FRP reinforcement due to its corrosion resistance, lightweight properties, and high tensile strength compared to traditional steel reinforcement. Innovations in hybrid reinforcement systems integrating FRP and steel aim to optimize structural performance and durability in harsh environments. Research advancements in sustainable manufacturing and cost reduction for FRP materials are expected to accelerate their widespread application in infrastructure projects.

Corrosion resistance

FRP reinforcement offers superior corrosion resistance compared to steel reinforcement, making it ideal for structures exposed to harsh environments and reducing maintenance costs.

Tensile strength

FRP reinforcement offers tensile strength up to twice that of traditional steel reinforcement, making it highly effective for corrosion-prone environments.

Modulus of elasticity

FRP reinforcement has a lower modulus of elasticity, typically ranging from 30 to 60 GPa, compared to steel reinforcement's modulus of approximately 200 GPa, influencing the stiffness and deformation behavior of reinforced concrete structures.

Bond behavior

FRP reinforcement exhibits superior corrosion resistance and consistent bond strength in aggressive environments compared to steel reinforcement, which often suffers bond degradation due to corrosion-induced interface deterioration.

Creep rupture

FRP reinforcement exhibits significantly lower creep rupture risk compared to steel reinforcement due to its superior corrosion resistance and stable long-term tensile behavior under sustained loads.

Alkali resistance

FRP reinforcement exhibits superior alkali resistance compared to steel reinforcement, preventing corrosion and enhancing durability in concrete structures exposed to alkaline environments.

Anisotropy

FRP reinforcement exhibits pronounced anisotropy with high tensile strength along fiber directions, contrasting with the isotropic mechanical properties of steel reinforcement.

Fatigue performance

FRP reinforcement demonstrates superior fatigue performance compared to steel reinforcement due to its corrosion resistance and high tensile strength retention under cyclic loading.

Shear transfer

FRP reinforcement provides superior corrosion resistance and lightweight properties while offering comparable shear transfer capacity to steel reinforcement in concrete structures.

Magnetic neutrality

FRP reinforcement offers magnetic neutrality, making it ideal for applications where steel reinforcement's magnetic interference could disrupt sensitive electronic equipment or magnetic resonance imaging (MRI) environments.

FRP reinforcement vs steel reinforcement Infographic

njnir.com

njnir.com