Geopolymer concrete offers superior durability and environmental benefits compared to traditional Portland cement by significantly reducing carbon emissions during production. Its enhanced chemical resistance and rapid strength gain make it ideal for infrastructure exposed to harsh conditions. Geopolymer concrete also utilizes industrial by-products, promoting sustainable construction practices without compromising structural integrity.

Table of Comparison

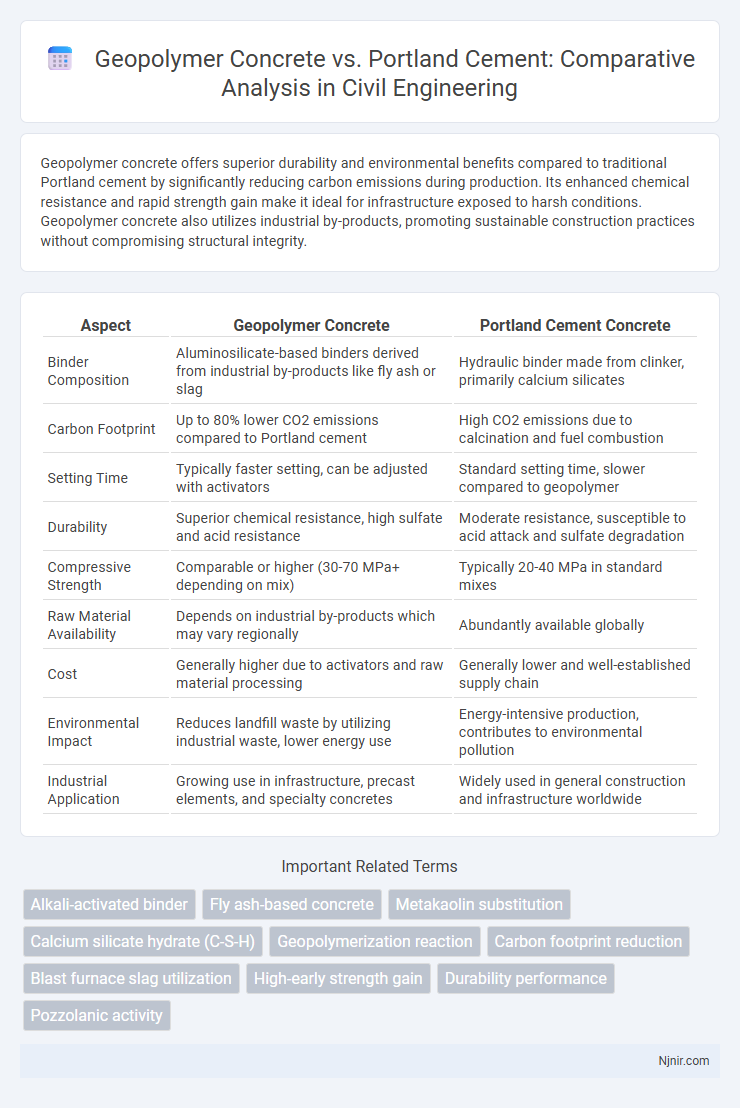

| Aspect | Geopolymer Concrete | Portland Cement Concrete |

|---|---|---|

| Binder Composition | Aluminosilicate-based binders derived from industrial by-products like fly ash or slag | Hydraulic binder made from clinker, primarily calcium silicates |

| Carbon Footprint | Up to 80% lower CO2 emissions compared to Portland cement | High CO2 emissions due to calcination and fuel combustion |

| Setting Time | Typically faster setting, can be adjusted with activators | Standard setting time, slower compared to geopolymer |

| Durability | Superior chemical resistance, high sulfate and acid resistance | Moderate resistance, susceptible to acid attack and sulfate degradation |

| Compressive Strength | Comparable or higher (30-70 MPa+ depending on mix) | Typically 20-40 MPa in standard mixes |

| Raw Material Availability | Depends on industrial by-products which may vary regionally | Abundantly available globally |

| Cost | Generally higher due to activators and raw material processing | Generally lower and well-established supply chain |

| Environmental Impact | Reduces landfill waste by utilizing industrial waste, lower energy use | Energy-intensive production, contributes to environmental pollution |

| Industrial Application | Growing use in infrastructure, precast elements, and specialty concretes | Widely used in general construction and infrastructure worldwide |

Introduction to Geopolymer Concrete and Portland Cement

Geopolymer concrete is an innovative construction material synthesized from industrial byproducts like fly ash and slag, offering high durability and reduced carbon emissions compared to traditional Portland cement. Portland cement is a hydraulic binder made primarily from clinker derived from limestone and clay, widely used in conventional concrete due to its strong binding properties. Geopolymer concrete's chemical composition, based on aluminosilicate materials activated by alkaline solutions, leads to enhanced resistance to chemicals and heat, distinguishing it from the calcium silicate hydrate structure of Portland cement.

Historical Development and Evolution

Geopolymer concrete emerged in the late 20th century as an eco-friendly alternative to Portland cement, which has been the dominant binding material in construction since the early 19th century. Portland cement's development, initiated by Joseph Aspdin in 1824, catalyzed modern concrete technology with widespread use due to its strength and versatility. The evolution of geopolymer concrete, based on aluminosilicate materials activated by alkaline solutions, reflects a strategic shift towards sustainable construction practices driven by rising environmental concerns and the demand for lower carbon emissions.

Chemical Composition and Bonding Mechanisms

Geopolymer concrete utilizes aluminosilicate materials activated by alkaline solutions, forming strong covalent bonds through geopolymerization, resulting in a three-dimensional polymeric chain structure. Portland cement relies on calcium silicate hydrates (C-S-H) formed by hydration reactions producing primarily ionic and hydrogen bonds, contributing to its compressive strength. The distinct chemical compositions dictate differing bond strengths and durability, with geopolymer concrete offering superior chemical resistance due to its inorganic polymer matrix.

Manufacturing Processes and Raw Materials

Geopolymer concrete utilizes industrial by-products like fly ash and slag combined with alkaline activators, resulting in a lower carbon footprint compared to Portland cement, which relies heavily on limestone and clay subjected to high-temperature kiln processing. The manufacturing process of geopolymer concrete involves geopolymerization, a chemical reaction between aluminosilicate materials and alkaline solutions, contrasting with the calcination process in Portland cement production that releases significant CO2 emissions. Raw materials for geopolymer concrete are often sourced from waste streams, promoting sustainability, whereas Portland cement extraction depletes natural resources and contributes more extensively to environmental degradation.

Environmental Impact and Sustainability

Geopolymer concrete significantly reduces carbon emissions compared to Portland cement by utilizing industrial by-products like fly ash and slag, which minimizes the need for energy-intensive clinker production. Its production releases up to 80% less CO2, enhancing sustainability by lowering the overall environmental footprint and reducing reliance on virgin materials. The durability and chemical resistance of geopolymer concrete also contribute to longer service life and less frequent repairs, promoting resource conservation and sustainable infrastructure development.

Mechanical Properties and Performance

Geopolymer concrete exhibits superior compressive strength and enhanced durability compared to traditional Portland cement concrete, making it ideal for high-performance structural applications. Its resistance to chemical attacks, high thermal stability, and lower shrinkage contribute to extended service life and reduced maintenance costs. The improved mechanical properties stem from its aluminosilicate binder, which provides a denser microstructure and better bonding with aggregates.

Durability and Long-Term Behavior

Geopolymer concrete exhibits superior durability compared to Portland cement, showcasing enhanced resistance to chemical attacks, sulfate exposure, and high temperatures due to its inorganic polymer matrix. Long-term behavior of geopolymer concrete includes reduced permeability and minimal shrinkage, contributing to prolonged structural integrity and reduced maintenance costs. Portland cement, while widely used, tends to undergo carbonation and chloride ingress over time, which can compromise durability and increase susceptibility to reinforcement corrosion.

Cost Analysis and Economic Feasibility

Geopolymer concrete often demonstrates lower lifecycle costs compared to Portland cement due to reduced raw material expenses and lower carbon emissions, which can translate into economic incentives and compliance savings. The production of geopolymer concrete utilizes industrial by-products like fly ash or slag, reducing reliance on energy-intensive clinker, thereby lowering manufacturing costs and environmental levies. While initial setup costs for geopolymer technology may be higher, long-term financial feasibility improves through durability benefits and decreasing material costs as supply chains mature.

Applications in Modern Construction

Geopolymer concrete, with its superior resistance to high temperatures and chemical attacks, is increasingly preferred for infrastructure requiring enhanced durability, such as bridges, industrial flooring, and marine structures. Portland cement remains dominant in conventional building applications like residential and commercial construction due to its cost-effectiveness and widespread availability. Modern construction trends show a growing shift toward geopolymer concrete in sustainable projects aiming to reduce carbon footprints and improve long-term performance.

Future Trends and Research Directions

Geopolymer concrete is gaining traction as a sustainable alternative to Portland cement due to its lower carbon footprint and enhanced durability, driven by increasing regulatory pressures and environmental concerns. Future research focuses on optimizing raw material sources such as fly ash and slag, improving mix designs for better mechanical properties, and developing standardized protocols to facilitate large-scale adoption. Innovations in nanotechnology and hybrid composites aim to enhance geopolymer performance, positioning it as a key material in green construction and carbon-neutral infrastructure development.

Alkali-activated binder

Alkali-activated binders in geopolymer concrete offer superior environmental sustainability and enhanced chemical resistance compared to traditional Portland cement, making them an eco-friendly alternative for durable construction.

Fly ash-based concrete

Fly ash-based geopolymer concrete offers superior durability, lower carbon emissions, and enhanced chemical resistance compared to traditional Portland cement concrete.

Metakaolin substitution

Geopolymer concrete utilizing metakaolin as a partial replacement for Portland cement significantly enhances compressive strength and durability while reducing carbon emissions compared to traditional Portland cement concrete.

Calcium silicate hydrate (C-S-H)

Geopolymer concrete enhances durability by forming calcium-alumino-silicate-hydrate (C-A-S-H) gels instead of calcium silicate hydrate (C-S-H) found in Portland cement, resulting in lower calcium content and improved chemical resistance.

Geopolymerization reaction

Geopolymer concrete utilizes a geopolymerization reaction that chemically bonds aluminosilicate materials with alkaline activators, creating a highly durable, eco-friendly alternative to traditional Portland cement.

Carbon footprint reduction

Geopolymer concrete reduces carbon footprint by up to 80% compared to traditional Portland cement due to its lower calcination emissions and utilization of industrial byproducts.

Blast furnace slag utilization

Geopolymer concrete utilizes blast furnace slag as a sustainable aluminosilicate source, significantly reducing carbon emissions compared to traditional Portland cement production.

High-early strength gain

Geopolymer concrete achieves high-early strength gain up to 70% faster than traditional Portland cement, making it ideal for rapid construction projects.

Durability performance

Geopolymer concrete exhibits superior durability performance compared to Portland cement by demonstrating enhanced resistance to chemical attack, thermal stability, and reduced permeability, which significantly extends structural lifespan.

Pozzolanic activity

Geopolymer concrete exhibits higher pozzolanic activity than Portland cement due to its aluminosilicate-rich precursors that enhance strength and durability through superior chemical reactions.

Geopolymer concrete vs Portland cement Infographic

njnir.com

njnir.com