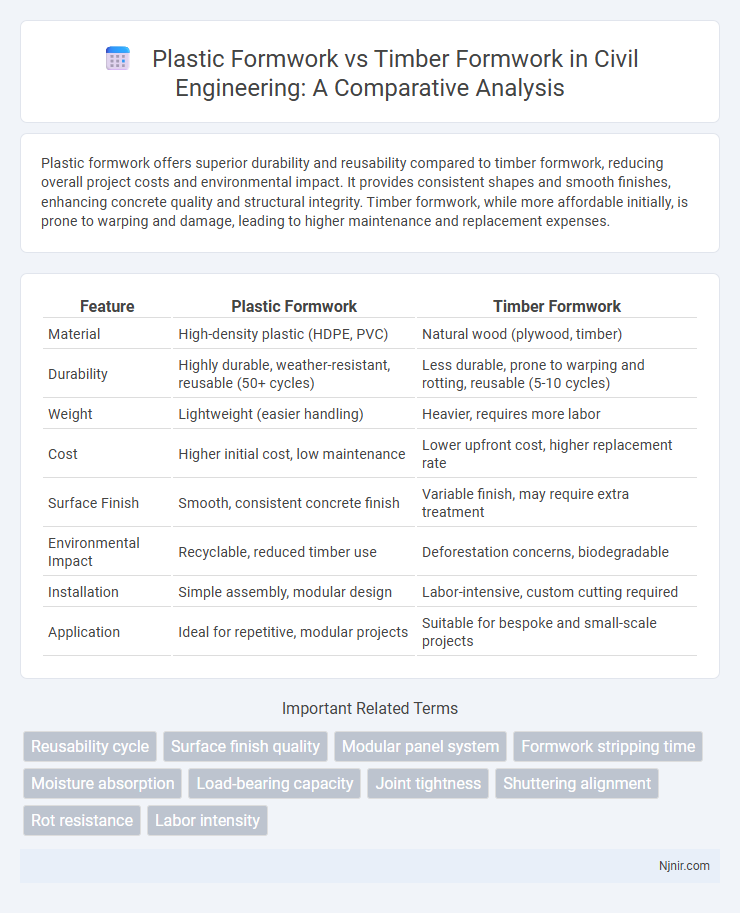

Plastic formwork offers superior durability and reusability compared to timber formwork, reducing overall project costs and environmental impact. It provides consistent shapes and smooth finishes, enhancing concrete quality and structural integrity. Timber formwork, while more affordable initially, is prone to warping and damage, leading to higher maintenance and replacement expenses.

Table of Comparison

| Feature | Plastic Formwork | Timber Formwork |

|---|---|---|

| Material | High-density plastic (HDPE, PVC) | Natural wood (plywood, timber) |

| Durability | Highly durable, weather-resistant, reusable (50+ cycles) | Less durable, prone to warping and rotting, reusable (5-10 cycles) |

| Weight | Lightweight (easier handling) | Heavier, requires more labor |

| Cost | Higher initial cost, low maintenance | Lower upfront cost, higher replacement rate |

| Surface Finish | Smooth, consistent concrete finish | Variable finish, may require extra treatment |

| Environmental Impact | Recyclable, reduced timber use | Deforestation concerns, biodegradable |

| Installation | Simple assembly, modular design | Labor-intensive, custom cutting required |

| Application | Ideal for repetitive, modular projects | Suitable for bespoke and small-scale projects |

Introduction to Concrete Formwork

Concrete formwork serves as a mold to shape and support fresh concrete until it hardens, with plastic formwork emerging as a modern alternative to traditional timber formwork. Plastic formwork offers advantages such as lightweight handling, reusability, and resistance to moisture and termites, resulting in reduced labor and material costs compared to timber. Timber formwork remains favored for its availability and ease of customization but suffers from lower durability and higher maintenance requirements.

Overview of Plastic Formwork

Plastic formwork offers a durable, lightweight alternative to traditional timber formwork, enhancing construction efficiency with its reusable and water-resistant properties. Its high strength-to-weight ratio and uniform surface finish reduce labor costs and improve concrete quality. Plastic formwork systems also contribute to sustainability by minimizing wood consumption and generating less waste on site.

Overview of Timber Formwork

Timber formwork consists of wooden panels and battens used to mold concrete structures, favored for its versatility, ease of cutting, and adaptability to complex shapes. It is cost-effective for small-scale projects, offers good insulation properties, and is lightweight, facilitating quick on-site assembly and modifications. However, timber formwork has a limited lifespan due to susceptibility to moisture, warping, and damage, requiring careful maintenance or replacement after multiple uses.

Material Properties: Plastic vs Timber

Plastic formwork offers superior durability, resistance to moisture, and consistent strength compared to timber formwork, which is prone to warping, rotting, and insect damage. The non-porous surface of plastic formwork enhances concrete finish quality and reduces the need for release agents, whereas timber's porous nature often leads to variable surface textures and higher maintenance. Plastic's lightweight and reusable characteristics contribute to better long-term cost efficiency and sustainability than traditional timber materials.

Installation Process Comparison

Plastic formwork offers faster installation due to its lightweight design and modular interlocking system, reducing labor costs and time on construction sites. Timber formwork requires more manual adjustments and skilled labor to cut, align, and secure panels, leading to longer setup periods. The durability and reusable nature of plastic formwork contribute to efficient project timelines compared to the often single-use or limited reusability of timber formwork.

Cost Analysis: Plastic vs Timber Formwork

Plastic formwork offers higher upfront costs compared to timber but provides significant long-term savings due to its durability and reusability, reducing replacement frequency. Timber formwork has lower initial investment yet incurs higher maintenance and disposal expenses, especially on large-scale or repetitive projects. Cost efficiency of plastic formwork improves notably in projects requiring multiple cycles, making it economically advantageous over timber in the extended term.

Durability and Lifespan

Plastic formwork offers superior durability compared to timber formwork due to its resistance to moisture, chemicals, and insect damage, resulting in a longer lifespan that can exceed 100 uses. Timber formwork is prone to warping, rotting, and degradation after repeated exposure to concrete and water, typically lasting only 10 to 15 uses. The enhanced longevity and minimal maintenance of plastic formwork make it a cost-effective and sustainable option for repetitive concrete casting projects.

Environmental Impact and Sustainability

Plastic formwork offers enhanced sustainability through its recyclability and durability, reducing waste and the demand for raw materials compared to timber formwork, which relies heavily on deforestation and has limited reusability. Timber formwork contributes to environmental degradation due to frequent replacement needs and its carbon footprint from logging and processing. The long lifespan and lower maintenance requirements of plastic formwork significantly decrease environmental impact, aligning better with green building practices and sustainable construction goals.

Suitability for Different Construction Projects

Plastic formwork offers high durability and reusability, making it ideal for repetitive, large-scale projects such as commercial buildings and infrastructure works. Timber formwork is more suitable for smaller, custom or irregular construction tasks due to its flexibility and ease of on-site modification. Projects requiring precise finishes and rapid assembly benefit significantly from plastic formwork's uniformity and lightweight properties.

Conclusion: Choosing the Right Formwork

Plastic formwork offers superior durability, reusability, and resistance to water and chemicals compared to timber formwork, which is more prone to damage and limited in lifespan. Timber formwork remains cost-effective for small or short-term projects but requires frequent replacement and maintenance. Selecting the right formwork depends on project scale, budget, and environmental considerations, with plastic formwork favored for long-term efficiency and sustainability.

Reusability cycle

Plastic formwork offers a significantly higher reusability cycle, often exceeding 100 uses, compared to timber formwork, which typically lasts for 10 to 15 uses before degradation.

Surface finish quality

Plastic formwork delivers superior surface finish quality with smoother, more uniform concrete surfaces compared to timber formwork, which often results in rougher textures and requires additional finishing.

Modular panel system

Modular panel systems in plastic formwork offer superior durability, faster assembly, and repeated reuse compared to traditional timber formwork, enhancing construction efficiency and cost-effectiveness.

Formwork stripping time

Plastic formwork reduces formwork stripping time by enabling faster curing and easier demolding compared to traditional timber formwork.

Moisture absorption

Plastic formwork exhibits significantly lower moisture absorption compared to timber formwork, enhancing durability and reducing susceptibility to warping and fungal growth.

Load-bearing capacity

Plastic formwork offers higher load-bearing capacity than timber formwork due to its uniform strength, resistance to deformation, and enhanced durability under heavy construction loads.

Joint tightness

Plastic formwork provides superior joint tightness compared to timber formwork due to its precise manufacturing tolerances and durable, non-absorbent surfaces.

Shuttering alignment

Plastic formwork provides superior shuttering alignment compared to timber formwork due to its consistent modular design and resistance to warping or swelling.

Rot resistance

Plastic formwork offers superior rot resistance compared to timber formwork, ensuring greater durability and reduced maintenance in construction projects.

Labor intensity

Plastic formwork reduces labor intensity by offering lightweight, modular components that are easier to assemble and disassemble compared to traditional, heavier timber formwork.

plastic formwork vs timber formwork Infographic

njnir.com

njnir.com