Digital twins offer real-time data integration and dynamic simulation capabilities that physical models cannot provide, enabling continuous monitoring and predictive analysis of infrastructure performance. Physical models, while tangible and intuitive for spatial visualization, lack the ability to update in real-time or simulate complex environmental interactions accurately. Digital twins enhance project management and maintenance strategies by providing accurate, scalable, and interactive representations of civil engineering assets.

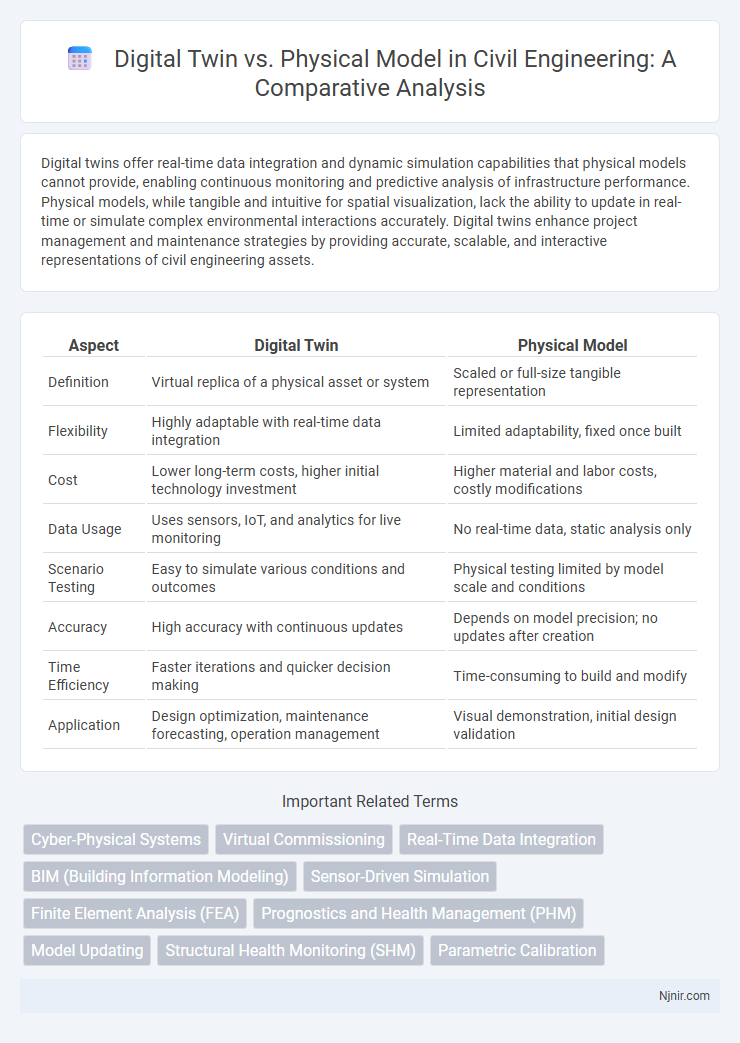

Table of Comparison

| Aspect | Digital Twin | Physical Model |

|---|---|---|

| Definition | Virtual replica of a physical asset or system | Scaled or full-size tangible representation |

| Flexibility | Highly adaptable with real-time data integration | Limited adaptability, fixed once built |

| Cost | Lower long-term costs, higher initial technology investment | Higher material and labor costs, costly modifications |

| Data Usage | Uses sensors, IoT, and analytics for live monitoring | No real-time data, static analysis only |

| Scenario Testing | Easy to simulate various conditions and outcomes | Physical testing limited by model scale and conditions |

| Accuracy | High accuracy with continuous updates | Depends on model precision; no updates after creation |

| Time Efficiency | Faster iterations and quicker decision making | Time-consuming to build and modify |

| Application | Design optimization, maintenance forecasting, operation management | Visual demonstration, initial design validation |

Introduction to Digital Twins and Physical Models

Digital twins are virtual replicas of physical systems that enable real-time monitoring, simulation, and predictive analytics by integrating data from sensors and IoT devices. Physical models are tangible, scaled-down representations used to study structural or functional aspects of real-world objects but lack dynamic data integration. The convergence of digital twin technology with advanced data analytics provides a more comprehensive and interactive understanding of system behavior compared to static physical models.

Evolution of Modeling Techniques in Civil Engineering

Digital twin technology has revolutionized civil engineering modeling by integrating real-time data analytics with virtual representations, surpassing traditional physical models that rely solely on static, scaled replicates of structures. The evolution from physical to digital models enables continuous monitoring, predictive maintenance, and enhanced simulation accuracy, improving decision-making throughout a project's lifecycle. Advanced sensors, IoT integration, and AI-driven analytics underpin digital twins, offering dynamic, data-rich environments that adapt to changing conditions in real time, unlike conventional physical models.

Key Features of Digital Twin Technology

Digital Twin technology enables real-time data integration, creating dynamic virtual replicas of physical assets that facilitate continuous monitoring and predictive analytics. Its key features include bidirectional communication, allowing synchronized updates and control between the digital and physical counterparts, and the ability to simulate scenarios to optimize performance and maintenance. This technology enhances decision-making through advanced AI algorithms and IoT connectivity, offering precise insights into operational conditions and lifecycle management.

Characteristics of Physical Modeling in Civil Engineering

Physical modeling in civil engineering involves creating tangible, scaled replicas of structures or systems to analyze behavior under various conditions, providing direct observation of phenomena such as stress, strain, and fluid flow. These models are characterized by their ability to replicate real-world physical interactions accurately, offering intuitive understanding and validation of design hypotheses. Limitations include challenges in scaling complex systems and the high cost and time required for construction and testing compared to digital simulations.

Comparative Analysis: Accuracy and Precision

Digital twins offer superior accuracy and precision compared to physical models by utilizing real-time data integration and advanced simulation algorithms, enabling continuous updates that reflect actual conditions. Physical models provide tangible representations but often lack the dynamic adaptability and fine-grained measurement capabilities inherent to digital twins. The precision of digital twins allows for predictive analytics and scenario testing with minute detail, whereas physical models are constrained by material limitations and static configurations.

Cost Implications: Digital vs Physical Approaches

Digital twins significantly reduce costs by enabling virtual testing and real-time monitoring, eliminating the need for expensive physical prototypes and minimizing material waste. Physical models require substantial investment in materials, labor, and space, along with ongoing maintenance expenses. The scalability and efficiency of digital twins offer long-term financial benefits through predictive maintenance and optimized operations.

Applications in Infrastructure Design and Maintenance

Digital twins provide real-time data integration and predictive analytics for infrastructure design and maintenance, enabling enhanced monitoring and early fault detection. Physical models offer tangible visualization and structural testing but lack dynamic feedback and real-time updates critical for adaptive management. Combining digital twin technology with physical modeling optimizes project outcomes by improving efficiency, accuracy, and lifecycle management of infrastructure assets.

Integration with Building Information Modeling (BIM)

Digital Twin technology offers dynamic, real-time integration with Building Information Modeling (BIM), enabling continuous data exchange and enhanced facility management through live sensor inputs and analytics. Physical models provide static, tangible representations of BIM designs but lack the ability to update or interact with live building performance data. Integrating Digital Twins with BIM improves predictive maintenance, energy efficiency, and operational decision-making by linking virtual models directly with real-world building conditions.

Challenges and Limitations of Each Method

Digital Twin technology faces challenges such as high implementation costs, complex data integration, and cybersecurity risks that may compromise system reliability. Physical models are limited by scale constraints, material inaccuracies, and the inability to dynamically simulate real-time changes or complex system interactions. Both methods struggle with ensuring precise representation and predictive accuracy, impacting decision-making effectiveness in engineering and manufacturing contexts.

Future Trends: The Convergence of Digital and Physical Models

Future trends point to the seamless integration of digital twin technology with physical models, enabling real-time data synchronization and predictive analytics for enhanced decision-making. Advances in IoT, AI, and edge computing are driving this convergence, facilitating more accurate simulations and adaptive control systems across industries such as manufacturing, urban planning, and healthcare. This fusion will revolutionize asset management by reducing costs, improving efficiency, and enabling proactive maintenance through continuous monitoring and virtual testing.

Cyber-Physical Systems

Digital twins integrate real-time data with physical model simulations within cyber-physical systems to enhance predictive maintenance, operational efficiency, and system optimization.

Virtual Commissioning

Virtual commissioning leverages Digital Twin technology to simulate, test, and optimize physical models of manufacturing systems, reducing downtime and enhancing accuracy compared to traditional physical model commissioning.

Real-Time Data Integration

Digital Twin enables real-time data integration by continuously synchronizing with physical models to provide dynamic, accurate simulations for enhanced decision-making.

BIM (Building Information Modeling)

Digital Twin in BIM continuously replicates real-time data for proactive building management, while Physical Models provide static representations mainly for design visualization.

Sensor-Driven Simulation

Sensor-driven simulation in digital twins enables real-time data integration and predictive analytics that surpass static physical models for dynamic system monitoring and optimization.

Finite Element Analysis (FEA)

Digital twin technology enhances Finite Element Analysis (FEA) accuracy by continuously integrating real-time sensor data from physical models, enabling dynamic simulation updates and predictive maintenance.

Prognostics and Health Management (PHM)

Digital twins provide real-time data integration and advanced analytics for Prognostics and Health Management (PHM), enabling more accurate failure predictions and optimized maintenance compared to traditional physical models.

Model Updating

Digital Twin enables real-time model updating by continuously integrating sensor data, whereas Physical Models require manual recalibration and lack dynamic feedback for adaptive accuracy.

Structural Health Monitoring (SHM)

Digital twins provide real-time, sensor-driven insights for Structural Health Monitoring (SHM) that surpass traditional physical models by enabling continuous data analysis and predictive maintenance of infrastructure.

Parametric Calibration

Digital Twin leverages parametric calibration by continuously updating virtual model parameters with real-time sensor data for precise physical behavior replication, unlike static physical models.

Digital Twin vs Physical Model Infographic

njnir.com

njnir.com