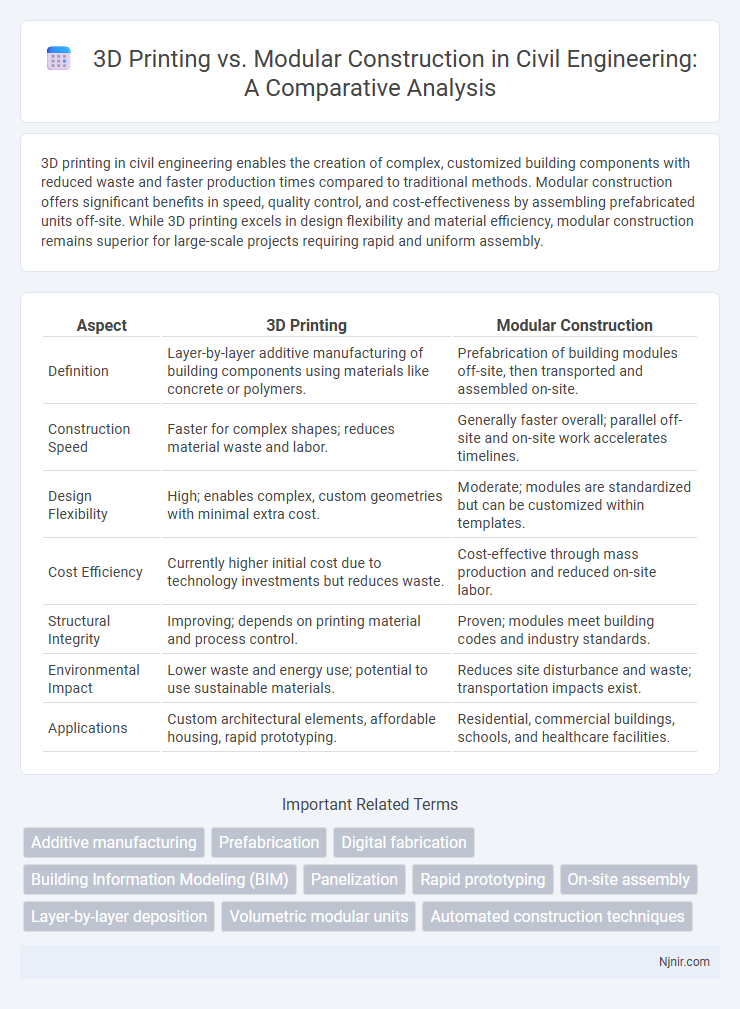

3D printing in civil engineering enables the creation of complex, customized building components with reduced waste and faster production times compared to traditional methods. Modular construction offers significant benefits in speed, quality control, and cost-effectiveness by assembling prefabricated units off-site. While 3D printing excels in design flexibility and material efficiency, modular construction remains superior for large-scale projects requiring rapid and uniform assembly.

Table of Comparison

| Aspect | 3D Printing | Modular Construction |

|---|---|---|

| Definition | Layer-by-layer additive manufacturing of building components using materials like concrete or polymers. | Prefabrication of building modules off-site, then transported and assembled on-site. |

| Construction Speed | Faster for complex shapes; reduces material waste and labor. | Generally faster overall; parallel off-site and on-site work accelerates timelines. |

| Design Flexibility | High; enables complex, custom geometries with minimal extra cost. | Moderate; modules are standardized but can be customized within templates. |

| Cost Efficiency | Currently higher initial cost due to technology investments but reduces waste. | Cost-effective through mass production and reduced on-site labor. |

| Structural Integrity | Improving; depends on printing material and process control. | Proven; modules meet building codes and industry standards. |

| Environmental Impact | Lower waste and energy use; potential to use sustainable materials. | Reduces site disturbance and waste; transportation impacts exist. |

| Applications | Custom architectural elements, affordable housing, rapid prototyping. | Residential, commercial buildings, schools, and healthcare facilities. |

Introduction to Modern Construction Methods

3D printing and modular construction represent innovative advances in modern construction methods, offering significant improvements in speed, cost efficiency, and customization. 3D printing utilizes additive manufacturing to create precise building components layer by layer, reducing waste and enabling complex designs. Modular construction involves fabricating sections off-site in controlled environments, ensuring quality control and rapid assembly on-site, transforming traditional building processes.

Overview of 3D Printing in Civil Engineering

3D printing in civil engineering revolutionizes construction by enabling the creation of complex structures through additive manufacturing processes, significantly reducing material waste and labor costs. This technology uses advanced materials like concrete mixtures with enhanced durability and precision, allowing for faster project completion compared to traditional methods. Integration with digital design tools enhances customization and scalability, positioning 3D printing as a transformative approach in modern construction practices.

Fundamentals of Modular Construction

Modular construction involves the prefabrication of building components in controlled factory settings, enabling faster on-site assembly and reduced labor costs compared to traditional methods. This approach emphasizes standardized modules that ensure quality control, precision engineering, and efficient transportation logistics. The fundamentals revolve around scalability, repeatability, and integration with architectural design, distinguishing it from the additive layering process used in 3D printing.

Technology and Workflow Comparison

3D printing in construction utilizes additive manufacturing technology to create complex building components layer by layer, enabling precise customization and rapid prototyping with minimal material waste. Modular construction involves prefabricating standardized modules in controlled factory settings before assembling them on-site, streamlining workflows through parallel production and reducing project timelines. While 3D printing offers flexibility for intricate designs, modular construction excels in scalability and efficiency through repetitive, assembly-line processes.

Material Selection and Performance

3D printing in construction utilizes advanced materials such as concrete composites and thermoplastics, enabling intricate designs and rapid prototyping with reduced waste. Modular construction relies on pre-fabricated materials like steel, timber, and engineered wood, optimized for durability and ease of assembly in controlled factory environments. Both methods enhance material performance by improving structural integrity and sustainability, but 3D printing offers more customization while modular construction provides consistent quality and faster on-site installation.

Speed, Cost, and Scalability Factors

3D printing accelerates construction by fabricating complex components rapidly with reduced labor, cutting overall project time significantly compared to traditional methods. Modular construction offers cost savings through off-site mass production and standardized units, enhancing quality control and reducing waste, though initial setup expenses can be high. Scalability favors modular construction due to its repeatable process and ability to produce large volumes efficiently, whereas 3D printing excels in customization but faces challenges in scaling for extensive builds.

Design Flexibility and Customization

3D printing offers unparalleled design flexibility by enabling complex geometries and intricate details that are difficult to achieve with traditional methods, supporting highly customized architectural features. Modular construction provides customization through pre-fabricated modules that can be combined in various configurations, but it is often limited by standardized module dimensions and factory constraints. While 3D printing excels in bespoke, intricate designs, modular construction is ideal for faster assembly of customizable yet uniform components, balancing speed and adaptability.

Environmental Impact and Sustainability

3D printing significantly reduces construction waste by using precise material deposition, minimizing excess and promoting resource efficiency, while modular construction decreases site disruption and enables recycling of standardized components. Both technologies lower carbon emissions compared to traditional methods, with 3D printing's potential for using sustainable materials like bio-based plastics and modular construction's ability to optimize transportation logistics and reduce energy consumption during assembly. Emphasizing circular economy principles, these innovative approaches enhance sustainable building practices by reducing environmental footprint and supporting energy-efficient designs.

Challenges and Limitations

3D printing in construction faces challenges such as limited material diversity, slow printing speeds for large-scale projects, and high initial equipment costs, restricting widespread adoption. Modular construction struggles with transportation logistics, design constraints due to prefabrication standards, and site assembly complexities that can delay project timelines. Both methods require significant coordination between design, manufacturing, and construction teams to address integration issues and ensure structural integrity.

Future Trends and Industry Adoption

3D printing is rapidly advancing in the construction industry with innovations in large-scale printers and eco-friendly materials, enabling faster, cost-effective, and highly customizable building components. Modular construction continues to gain traction globally due to its efficiency in reducing on-site labor and waste, supported by significant investments from real estate developers aiming for sustainable urban projects. Industry adoption trends indicate a hybrid approach, combining 3D printing's precision with modular methods to enhance construction speed and design flexibility for future smart cities.

Additive manufacturing

Additive manufacturing in 3D printing enables precise, cost-effective production of complex modular construction components, significantly reducing material waste and construction time compared to traditional modular methods.

Prefabrication

Prefabrication in modular construction allows for precise, large-scale component assembly offsite, while 3D printing enables customizable, complex designs with rapid prototyping and material efficiency.

Digital fabrication

Digital fabrication in 3D printing enables precise, customizable building components, while modular construction emphasizes mass production and on-site assembly efficiency.

Building Information Modeling (BIM)

Building Information Modeling (BIM) enhances precision and coordination in both 3D printing and modular construction, enabling real-time data integration, clash detection, and efficient project management for optimized building workflows.

Panelization

Panelization in modular construction offers faster assembly and superior structural consistency compared to 3D printing, which excels in intricate custom designs but faces scale limitations.

Rapid prototyping

3D printing enables rapid prototyping in construction by quickly producing complex, customizable components, significantly reducing design iteration time compared to traditional modular construction methods.

On-site assembly

3D printing significantly reduces on-site assembly time by fabricating complex building components as single units, whereas modular construction relies on assembling pre-fabricated modules, requiring more extensive on-site integration.

Layer-by-layer deposition

Layer-by-layer deposition distinguishes 3D printing by enabling precise, customizable fabrication of complex architectural components, while modular construction relies on assembling pre-fabricated units for faster on-site assembly.

Volumetric modular units

Volumetric modular units in modular construction offer faster assembly and consistent quality compared to the customizable but slower production process of 3D printing.

Automated construction techniques

Automated construction techniques like 3D printing enable precise, rapid fabrication of complex building components, while modular construction emphasizes factory-built, pre-assembled modules for scalable, efficient on-site assembly.

3D printing vs modular construction Infographic

njnir.com

njnir.com