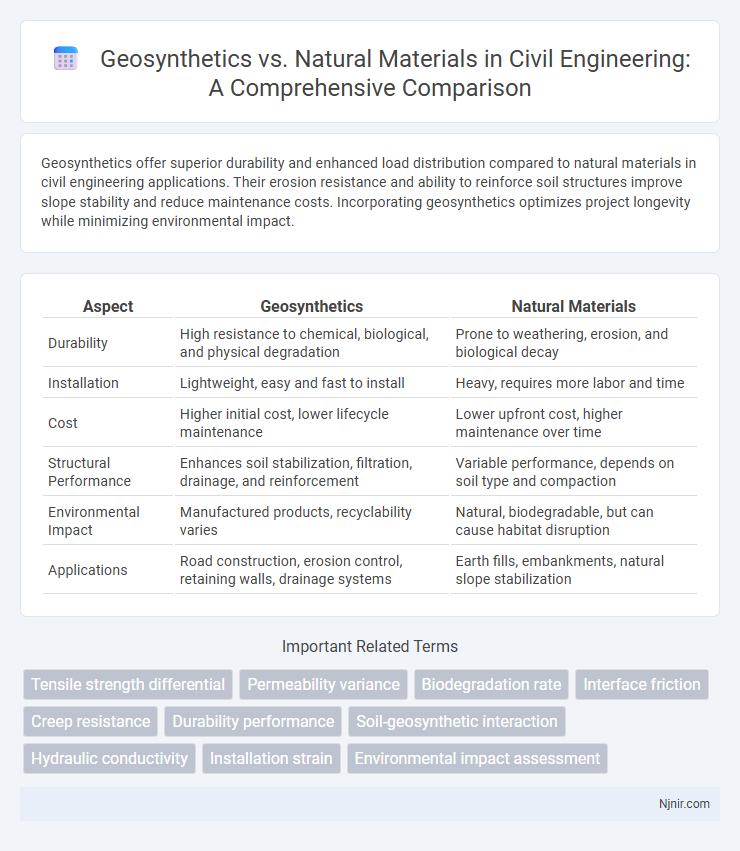

Geosynthetics offer superior durability and enhanced load distribution compared to natural materials in civil engineering applications. Their erosion resistance and ability to reinforce soil structures improve slope stability and reduce maintenance costs. Incorporating geosynthetics optimizes project longevity while minimizing environmental impact.

Table of Comparison

| Aspect | Geosynthetics | Natural Materials |

|---|---|---|

| Durability | High resistance to chemical, biological, and physical degradation | Prone to weathering, erosion, and biological decay |

| Installation | Lightweight, easy and fast to install | Heavy, requires more labor and time |

| Cost | Higher initial cost, lower lifecycle maintenance | Lower upfront cost, higher maintenance over time |

| Structural Performance | Enhances soil stabilization, filtration, drainage, and reinforcement | Variable performance, depends on soil type and compaction |

| Environmental Impact | Manufactured products, recyclability varies | Natural, biodegradable, but can cause habitat disruption |

| Applications | Road construction, erosion control, retaining walls, drainage systems | Earth fills, embankments, natural slope stabilization |

Introduction to Geosynthetics and Natural Materials

Geosynthetics, engineered polymeric products such as geotextiles, geomembranes, and geogrids, offer enhanced durability, permeability control, and reinforcement compared to natural materials like soil, clay, and gravel. In civil engineering applications, geosynthetics improve stability, erosion control, and drainage while reducing construction time and costs. Natural materials, though abundant and cost-effective, often lack the consistency and performance reliability required for modern infrastructure projects.

Historical Overview of Construction Materials

Geosynthetics have revolutionized construction since their introduction in the 1950s, offering superior strength, durability, and flexibility compared to traditional natural materials like soil, sand, and gravel. Historically, natural materials were prevalent due to availability and cost, but limitations in load-bearing capacity and susceptibility to erosion prompted innovation. The evolution from natural to synthetic materials marked a significant advancement in civil engineering, enabling enhanced soil stabilization, erosion control, and drainage solutions across infrastructure projects.

Material Properties: Strength and Durability

Geosynthetics exhibit superior strength-to-weight ratios compared to natural materials, enabling enhanced load-bearing capacity and long-term performance in civil engineering applications. Their engineered polymers resist biological degradation, UV exposure, and chemical attacks, ensuring prolonged durability in harsh environmental conditions. Unlike natural materials that vary in composition and quality, geosynthetics provide consistent mechanical properties tailored to specific project requirements.

Environmental Impact and Sustainability

Geosynthetics significantly reduce environmental impact by minimizing the need for natural resource extraction and lowering greenhouse gas emissions compared to conventional materials like gravel or clay. Their durability and resistance to degradation enhance sustainability through extended lifespan and reduced maintenance frequency in infrastructure projects. Using geosynthetics in earthworks and erosion control helps preserve natural habitats and reduces soil disturbance, contributing to improved ecological balance.

Cost Analysis and Economic Considerations

Geosynthetics offer significant cost advantages over natural materials due to reduced transportation expenses, faster installation times, and lower labor costs. Their durability and resistance to environmental degradation result in decreased maintenance and replacement expenses, enhancing long-term economic efficiency. Investment in geosynthetic solutions often leads to overall project savings by minimizing material volume requirements and optimizing construction schedules.

Installation Techniques and Construction Methods

Geosynthetics offer streamlined installation techniques with lightweight rolls that reduce labor and equipment needs compared to bulky natural materials like gravel and sand. Construction methods utilizing geosynthetics incorporate precise placement, often with automated machinery, ensuring consistent layering and compaction, which enhances soil reinforcement and drainage systems. In contrast, natural material installation requires extensive handling, sorting, and compaction, increasing time and cost while limiting uniformity in large-scale civil engineering projects.

Performance in Soil Stabilization

Geosynthetics outperform natural materials in soil stabilization by providing superior tensile strength, durability, and resistance to environmental degradation. Unlike natural materials such as sands and gravels, geosynthetics maintain structural integrity under heavy load conditions and minimize soil erosion effectively. Their engineered properties enable consistent reinforcement, filtration, and drainage, enhancing overall soil stability and prolonging infrastructure lifespan.

Applications in Geotechnical Engineering

Geosynthetics offer superior durability, permeability control, and reinforcement capabilities compared to natural materials in geotechnical engineering applications such as slope stabilization, retaining walls, and soil erosion prevention. Their engineered properties enable enhanced load distribution, improved soil compaction, and effective drainage management, which natural materials often lack. These advantages result in reduced construction costs, increased project lifespan, and greater environmental sustainability.

Long-Term Maintenance Requirements

Geosynthetics exhibit significantly lower long-term maintenance requirements compared to natural materials due to their engineered durability and resistance to environmental degradation, such as UV exposure and chemical corrosion. While natural materials like gravel or clay often require periodic replenishment or stabilization to maintain structural integrity, geosynthetics maintain their performance over extended periods, reducing the frequency of repairs and related costs. Their enhanced lifespan and predictable deterioration rates make geosynthetics a cost-effective solution for infrastructure projects demanding minimal maintenance interventions.

Future Trends and Innovations in Civil Engineering Materials

Geosynthetics are increasingly favored in civil engineering for their superior durability, cost-efficiency, and environmental impact compared to natural materials like sand, gravel, or clay. Innovations such as bio-based geotextiles, smart geosynthetics with embedded sensors, and multifunctional composite materials showcase the future trends, aiming to enhance sustainability, real-time monitoring, and structural performance. Integration of nanotechnology and recycled polymers in geosynthetics further positions these materials as pivotal in advancing resilient and eco-friendly infrastructure solutions.

Tensile strength differential

Geosynthetics exhibit significantly higher tensile strength compared to natural materials, providing superior reinforcement and durability in civil engineering applications.

Permeability variance

Geosynthetics typically exhibit controlled permeability levels significantly lower than the variable and often higher permeability of natural materials, enabling more precise fluid flow management in civil engineering applications.

Biodegradation rate

Geosynthetics exhibit significantly lower biodegradation rates compared to natural materials, enhancing their durability and longevity in environmental applications.

Interface friction

Geosynthetics exhibit higher interface friction coefficients compared to natural materials, enhancing soil reinforcement and stability in geotechnical engineering applications.

Creep resistance

Geosynthetics exhibit superior creep resistance compared to natural materials, maintaining long-term structural stability under sustained loads in engineering applications.

Durability performance

Geosynthetics exhibit superior durability performance compared to natural materials due to their enhanced resistance to environmental factors, chemical degradation, and mechanical stress.

Soil-geosynthetic interaction

Soil-geosynthetic interaction enhances reinforcement and stability by improving load distribution, reducing deformation, and increasing shear strength compared to natural materials alone.

Hydraulic conductivity

Geosynthetics exhibit significantly lower hydraulic conductivity than most natural materials, enhancing soil stabilization and seepage control in civil engineering applications.

Installation strain

Geosynthetics exhibit significantly lower installation strain compared to natural materials, enhancing durability and reducing deformation during construction.

Environmental impact assessment

Geosynthetics reduce environmental impact by minimizing soil erosion, controlling sedimentation, and requiring less natural resource extraction compared to traditional natural materials in construction projects.

geosynthetics vs natural materials Infographic

njnir.com

njnir.com