Prestressed concrete offers superior strength and durability compared to reinforced concrete by actively applying compressive stresses to counteract tensile forces, reducing the risk of cracking under load. Reinforced concrete relies on passive steel reinforcement, which can lead to greater deflection and potential corrosion over time. The enhanced load capacity and improved service life of prestressed concrete make it ideal for long-span structures and heavy load-bearing applications in civil engineering.

Table of Comparison

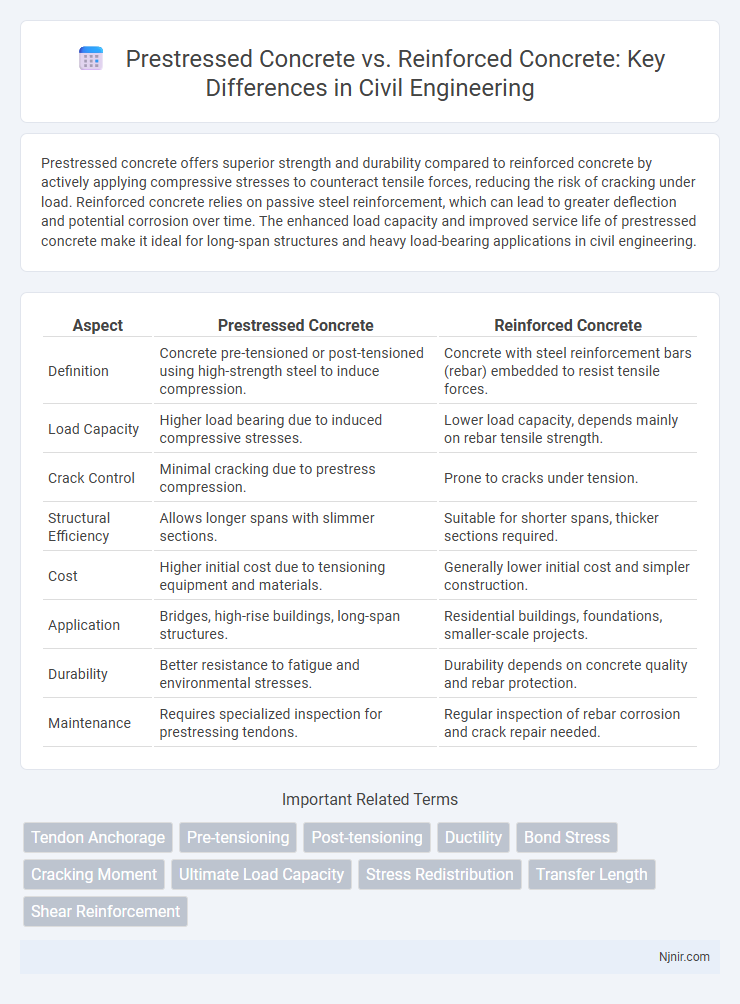

| Aspect | Prestressed Concrete | Reinforced Concrete |

|---|---|---|

| Definition | Concrete pre-tensioned or post-tensioned using high-strength steel to induce compression. | Concrete with steel reinforcement bars (rebar) embedded to resist tensile forces. |

| Load Capacity | Higher load bearing due to induced compressive stresses. | Lower load capacity, depends mainly on rebar tensile strength. |

| Crack Control | Minimal cracking due to prestress compression. | Prone to cracks under tension. |

| Structural Efficiency | Allows longer spans with slimmer sections. | Suitable for shorter spans, thicker sections required. |

| Cost | Higher initial cost due to tensioning equipment and materials. | Generally lower initial cost and simpler construction. |

| Application | Bridges, high-rise buildings, long-span structures. | Residential buildings, foundations, smaller-scale projects. |

| Durability | Better resistance to fatigue and environmental stresses. | Durability depends on concrete quality and rebar protection. |

| Maintenance | Requires specialized inspection for prestressing tendons. | Regular inspection of rebar corrosion and crack repair needed. |

Introduction to Prestressed and Reinforced Concrete

Prestressed concrete utilizes high-strength steel tendons tensioned before or after concrete casting, enhancing structural capacity by inducing compressive stresses that counteract tensile forces. Reinforced concrete incorporates steel bars or mesh embedded within to improve tensile strength, preventing cracking under load. The key distinction lies in prestressing applying pre-compression to concrete, whereas reinforcement provides passive resistance to tensile stresses during service.

Fundamental Concepts and Definitions

Prestressed concrete involves the application of internal compressive stresses through tensioned steel tendons before any external load is applied, effectively counteracting tensile stresses and minimizing cracking. Reinforced concrete combines concrete with embedded steel reinforcement bars to resist tensile forces after loads are applied, relying on the composite action between the concrete and steel. The fundamental difference lies in the timing and method of steel tensioning, with prestressing enhancing strength and durability by preloading the steel, whereas reinforced concrete depends on passive reinforcement responding to stress during service.

Material Composition and Construction Techniques

Prestressed concrete incorporates high-strength steel tendons tensioned before or after casting, enhancing tensile strength and reducing cracks compared to reinforced concrete, which uses conventional steel bars embedded in concrete. The construction of prestressed concrete requires specialized equipment to apply and maintain tension in the steel strands, allowing longer spans and thinner sections, whereas reinforced concrete construction involves simpler placement of rebar and concrete pouring. Material composition of prestressed concrete includes high-performance concrete mixed with corrosion-resistant steel cables, optimizing durability and load capacity beyond the embedded, non-tensioned steel reinforcement in traditional reinforced concrete.

Strength and Load-Bearing Capabilities

Prestressed concrete offers superior strength and load-bearing capabilities compared to reinforced concrete by introducing internal compressive stresses that counteract tensile forces, allowing it to support heavier loads and span longer distances without cracking. Reinforced concrete relies on steel reinforcement bars to carry tensile loads, but its overall strength is limited by the bond between concrete and steel, making it less effective in handling high-stress conditions. The enhanced prestressing technique significantly reduces deflection and improves durability, making prestressed concrete ideal for bridges, high-rise buildings, and large-span structures.

Durability and Service Life Comparison

Prestressed concrete exhibits significantly enhanced durability due to reduced tensile stresses, minimizing crack formation and corrosion risk in steel reinforcement, which extends the service life compared to conventional reinforced concrete. Reinforced concrete is more susceptible to deterioration from environmental factors such as chloride ingress and freeze-thaw cycles, leading to earlier maintenance and repair cycles. Studies indicate prestressed concrete structures can achieve service lives exceeding 75 years, surpassing the typical 50-year lifespan of standard reinforced concrete under similar exposure conditions.

Cost Implications and Economic Analysis

Prestressed concrete generally involves higher initial costs due to specialized materials and labor, but it offers superior durability and reduced maintenance expenses over time compared to reinforced concrete. Reinforced concrete has lower upfront costs, making it more economical for smaller projects, yet it may require more frequent repairs and longer construction periods, raising lifecycle costs. Economic analysis reveals prestressed concrete's long-term savings outweigh initial investments in large-scale infrastructure, whereas reinforced concrete remains cost-effective for less demanding applications.

Common Applications in Civil Engineering

Prestressed concrete is commonly used in long-span bridges, parking structures, and high-rise buildings where enhanced load-bearing capacity and crack control are critical. Reinforced concrete finds widespread application in foundations, slabs, beams, and columns due to its versatility and cost-effectiveness in supporting compressive and tensile loads. Civil engineers select prestressed concrete for structures requiring higher tensile strength and durability, while reinforced concrete suits general construction where moderate loads prevail.

Structural Performance Under Various Loads

Prestressed concrete demonstrates superior structural performance under various loads by effectively counteracting tensile stresses through induced compression, significantly reducing crack formation compared to reinforced concrete. Reinforced concrete relies on steel rebars to carry tensile stresses but is more susceptible to cracking and deflection under high or dynamic loads. Consequently, prestressed concrete offers enhanced durability, higher load-bearing capacity, and improved serviceability in bridges, beams, and other structural elements subjected to bending, shear, and fatigue.

Advantages and Limitations of Each System

Prestressed concrete offers higher load-carrying capacity and reduced crack widths compared to reinforced concrete, making it ideal for long-span structures and heavy loads. Reinforced concrete provides greater ductility and easier construction methods, proving advantageous for complex shapes and cost-effective projects. While prestressed concrete requires specialized skills and higher initial costs, reinforced concrete has limitations in tensile strength and is more prone to cracking under tensile stress.

Future Trends in Concrete Technology

Future trends in concrete technology emphasize the increased adoption of prestressed concrete due to its superior load-bearing capacity and durability compared to traditional reinforced concrete. Innovations such as ultra-high-performance concrete (UHPC) and fiber-reinforced polymers (FRP) are enhancing the efficiency and lifespan of prestressed elements in infrastructure projects. Sustainable practices, including carbon capture and recycled materials integration, are further driving the evolution of both prestressed and reinforced concrete toward greener, more resilient construction solutions.

Tendon Anchorage

Tendon anchorage in prestressed concrete ensures high tensile force transfer and durability, contrasting with reinforced concrete where steel reinforcement primarily relies on concrete bonding without specialized anchorage systems.

Pre-tensioning

Pre-tensioning in prestressed concrete involves stressing steel tendons before casting, enhancing load-bearing capacity and reducing concrete cracking compared to reinforced concrete.

Post-tensioning

Post-tensioning in prestressed concrete involves tensioning steel tendons after concrete curing, providing higher strength and crack control compared to reinforced concrete's embedded steel rebar.

Ductility

Prestressed concrete exhibits lower ductility compared to reinforced concrete due to its high initial compression, which limits its ability to undergo large deformations before failure.

Bond Stress

Prestressed concrete exhibits higher bond stress between steel and concrete compared to reinforced concrete, enhancing load transfer efficiency and structural performance.

Cracking Moment

Prestressed concrete significantly increases the cracking moment compared to reinforced concrete by applying pre-compression, which counteracts tensile stresses and delays crack initiation.

Ultimate Load Capacity

Prestressed concrete exhibits a higher ultimate load capacity than reinforced concrete due to its enhanced tensile strength from induced compressive stresses.

Stress Redistribution

Stress redistribution in prestressed concrete enhances load-bearing capacity by inducing compressive stresses that counteract tensile forces, whereas reinforced concrete relies primarily on steel reinforcement to resist tensile stresses without pre-applied compression.

Transfer Length

Transfer length in prestressed concrete is significantly shorter than in reinforced concrete due to the high initial tension in tendons that effectively transfer stress to the surrounding concrete.

Shear Reinforcement

Prestressed concrete requires less shear reinforcement than reinforced concrete due to its induced compressive stresses that counteract tensile forces and reduce shear cracks.

prestressed concrete vs reinforced concrete Infographic

njnir.com

njnir.com