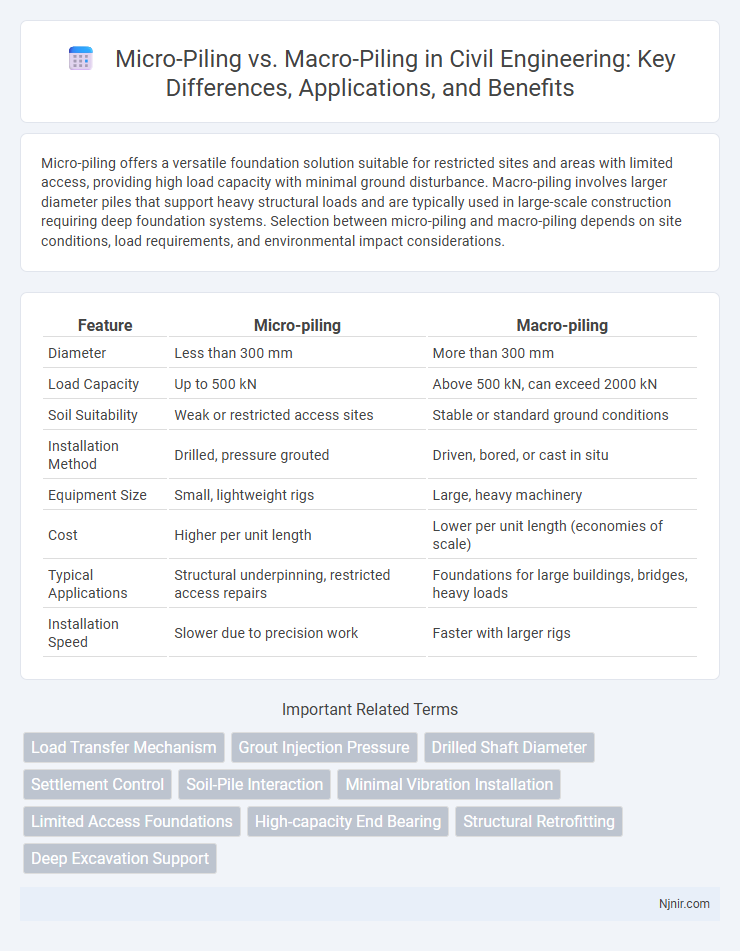

Micro-piling offers a versatile foundation solution suitable for restricted sites and areas with limited access, providing high load capacity with minimal ground disturbance. Macro-piling involves larger diameter piles that support heavy structural loads and are typically used in large-scale construction requiring deep foundation systems. Selection between micro-piling and macro-piling depends on site conditions, load requirements, and environmental impact considerations.

Table of Comparison

| Feature | Micro-piling | Macro-piling |

|---|---|---|

| Diameter | Less than 300 mm | More than 300 mm |

| Load Capacity | Up to 500 kN | Above 500 kN, can exceed 2000 kN |

| Soil Suitability | Weak or restricted access sites | Stable or standard ground conditions |

| Installation Method | Drilled, pressure grouted | Driven, bored, or cast in situ |

| Equipment Size | Small, lightweight rigs | Large, heavy machinery |

| Cost | Higher per unit length | Lower per unit length (economies of scale) |

| Typical Applications | Structural underpinning, restricted access repairs | Foundations for large buildings, bridges, heavy loads |

| Installation Speed | Slower due to precision work | Faster with larger rigs |

Introduction to Micro-piling vs Macro-piling

Micro-piling and macro-piling are deep foundation techniques used to transfer structural loads to stable soil or rock layers. Micro-piles are small-diameter, high-capacity piles typically ranging from 150mm to 300mm in diameter, ideal for sites with restricted access and limited headroom. Macro-piles, also known as driven piles or large-diameter bored piles, range from 600mm to several meters and are suited for heavy load-bearing applications and larger construction projects.

Definition and Technical Overview

Micro-piling involves the installation of small-diameter, high-capacity piles typically less than 300mm in diameter, designed to transfer loads through weak soil layers to stronger substrata. Macro-piling refers to large-diameter piles exceeding 600mm, used for heavy structural loads and deep foundation support in construction projects. Micro-piles utilize drilled shafts with high-strength steel bars, while macro-piles often employ driven or cast-in-place methods, each suited for specific geotechnical conditions and load requirements.

Historical Development and Application

Micro-piling originated in the 1950s as a solution for strengthening foundations in areas with restricted access and poor ground conditions, evolving with advancements in high-strength materials and drilling techniques. Macro-piling, developed earlier in the 20th century, became widely used for large-scale infrastructure projects requiring deep load-bearing capacity through massive structural elements. Both methods have diversified applications: micro-piles are preferred in retrofit and seismic upgrading of existing structures, while macro-piles are dominant in new construction of bridges, buildings, and heavy industrial facilities.

Material and Equipment Differences

Micro-piling uses small-diameter steel tubes or high-strength steel bars as primary materials, ideal for tight or restricted sites, while macro-piling relies on larger-diameter concrete or steel piles for heavy load-bearing applications. Equipment for micro-piling includes portable rotary or percussive drilling rigs capable of precise, small-scale installation, whereas macro-piling requires large, heavy-duty hammer or rotary rigs designed for deep, robust pile driving. Material selection and equipment scale impact cost, installation speed, and site accessibility, defining their suitability for different geotechnical conditions.

Load-Bearing Capacities

Micro-piling offers load-bearing capacities suitable for restricted access sites and unstable soils, typically supporting loads up to 2000 kN, whereas macro-piling can handle significantly higher loads exceeding 4000 kN due to larger diameters and deeper embedment. Load capacity in micro-piles depends on high-strength steel and grouting techniques, providing superior axial and lateral resistance in rehabilitation projects. Macro-piles deliver enhanced structural support for heavy infrastructure, making them ideal for bridges, high-rises, and large-scale foundations requiring substantial load distribution and transfer.

Installation Techniques and Site Requirements

Micro-piling involves installing small-diameter piles, typically less than 300 mm, using rotary drilling or impact techniques suited for confined spaces and low-headroom sites. Macro-piling, characterized by large-diameter piles often exceeding 600 mm, requires heavy machinery such as pile drivers or large rotary rigs, demanding extensive site access and space. Site conditions influence the choice; micro-piling is ideal for urban areas with restricted access and delicate structures, while macro-piling suits open sites with heavy load requirements and ample maneuverability.

Cost Implications and Budget Considerations

Micro-piling generally incurs higher initial costs due to the specialized equipment and skilled labor required, making it less suitable for projects with tight budgets. Macro-piling offers a more cost-effective solution for large-scale foundations as it uses larger piles that reduce installation time and material expenses. Budget considerations must include soil conditions, load requirements, and site accessibility to determine the most economical piling method without compromising structural integrity.

Typical Use Cases and Suitability

Micro-piling excels in applications requiring minimal disturbance, such as underpinning existing structures, working in confined spaces, or stabilizing foundations in urban environments. Macro-piling is more suitable for heavy load-bearing foundations in large-scale construction projects like bridges, high-rise buildings, and industrial facilities where significant load transfer to deeper soil strata is necessary. Selecting between micro-piling and macro-piling depends on load requirements, site constraints, and soil conditions to ensure optimal foundation stability and cost-efficiency.

Environmental Impact Comparison

Micro-piling generates significantly less vibration and noise, minimizing disturbance to surrounding ecosystems and urban areas, while using less material reduces carbon footprint. Macro-piling involves larger boreholes and more concrete, leading to higher resource consumption and potential soil displacement, increasing environmental disruption risks. Choosing micro-piles over macro-piles supports sustainable construction practices with lower ecological impact and improved ground stability in sensitive sites.

Future Trends in Foundation Piling

Future trends in foundation piling emphasize increased adoption of micro-piling techniques due to their minimal environmental impact, suitability for restricted access sites, and enhanced load-bearing capacity through advanced materials like high-strength steel and composite anchors. Macro-piling continues to evolve with innovations in automation and real-time monitoring systems that improve installation precision and reduce construction time, catering to large-scale infrastructure projects. Sustainable construction practices drive both micro and macro-piling advancements, integrating smart sensors for structural health monitoring and promoting the use of eco-friendly materials to meet stringent regulatory standards.

Load Transfer Mechanism

Micro-piling transfers load through skin friction along small-diameter piles embedded in varying soil strata, while macro-piling primarily relies on end-bearing capacity of larger-diameter piles resting on firm substrata.

Grout Injection Pressure

Micro-piling typically uses lower grout injection pressure ranging from 0.5 to 3 MPa for precise, small-diameter piles, while macro-piling requires higher pressure above 3 MPa to ensure stability in larger diameter piles.

Drilled Shaft Diameter

Micro-piling typically involves drilled shaft diameters less than 300 mm, while macro-piling utilizes larger diameters exceeding 600 mm for enhanced load-bearing capacity.

Settlement Control

Micro-piling offers superior settlement control in weak soil conditions due to its smaller diameter and higher adaptability, whereas macro-piling provides greater load capacity but may result in less precise settlement management.

Soil-Pile Interaction

Micro-piling offers superior soil-pile interaction in weak or constrained soils by minimizing disturbance and enhancing load transfer, whereas macro-piling is more effective in stable soils with higher load capacities.

Minimal Vibration Installation

Micro-piling offers a minimal vibration installation method compared to macro-piling, making it ideal for sensitive environments and structures requiring reduced ground disturbance.

Limited Access Foundations

Micro-piling offers an effective foundation solution for limited access sites due to its smaller diameter and adaptability, whereas macro-piling requires larger equipment and more space, making it less suitable for confined areas.

High-capacity End Bearing

Micro-piling offers high-capacity end bearing in compact spaces by utilizing small-diameter, high-strength piles, whereas macro-piling achieves end bearing through larger-diameter piles suited for heavy loads and extensive soil displacement.

Structural Retrofitting

Micro-piling provides precise load transfer and minimal vibration ideal for structural retrofitting in confined spaces, while macro-piling offers higher load capacity suited for larger-scale foundation reinforcement but with increased disturbance.

Deep Excavation Support

Micro-piling offers precise load-bearing and minimal vibration benefits for deep excavation support in confined spaces, while macro-piling provides greater load capacity and faster installation for large-scale underground projects.

Micro-piling vs Macro-piling Infographic

njnir.com

njnir.com