Cantilever bridges utilize projecting beams anchored only at one end, allowing them to span medium distances with strong support from piers, making them ideal for rugged terrains and heavy loads. Suspension bridges employ cables hung between towers and anchored at both ends to support the deck, enabling them to cover much longer spans with flexibility and reduced material usage. Both designs serve distinct structural needs, with cantilever bridges offering greater rigidity and suspension bridges excelling in spanning vast waterways.

Table of Comparison

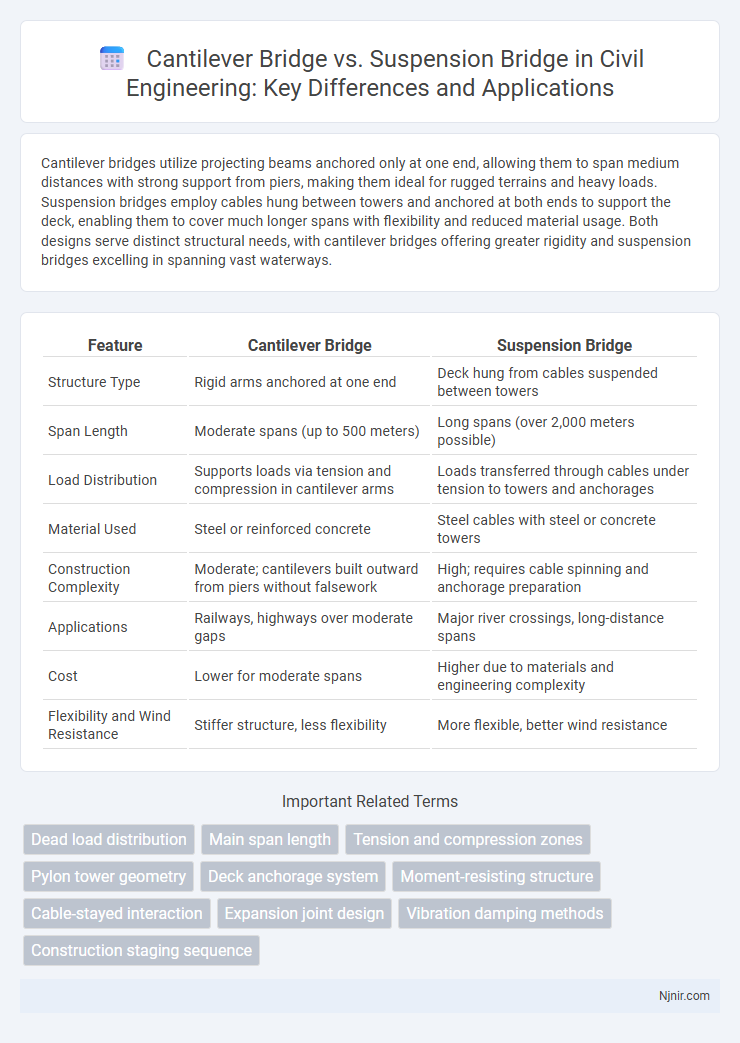

| Feature | Cantilever Bridge | Suspension Bridge |

|---|---|---|

| Structure Type | Rigid arms anchored at one end | Deck hung from cables suspended between towers |

| Span Length | Moderate spans (up to 500 meters) | Long spans (over 2,000 meters possible) |

| Load Distribution | Supports loads via tension and compression in cantilever arms | Loads transferred through cables under tension to towers and anchorages |

| Material Used | Steel or reinforced concrete | Steel cables with steel or concrete towers |

| Construction Complexity | Moderate; cantilevers built outward from piers without falsework | High; requires cable spinning and anchorage preparation |

| Applications | Railways, highways over moderate gaps | Major river crossings, long-distance spans |

| Cost | Lower for moderate spans | Higher due to materials and engineering complexity |

| Flexibility and Wind Resistance | Stiffer structure, less flexibility | More flexible, better wind resistance |

Introduction to Cantilever and Suspension Bridges

Cantilever bridges use projecting beams supported only at one end, allowing them to span long distances without external bracing. Suspension bridges feature cables suspended between towers, with vertical suspenders holding the deck, enabling flexible and aerodynamic structures ideal for very long spans. Both bridge types optimize load distribution but differ in construction methods and applications, with cantilever bridges often used for medium spans and suspension bridges preferred for the longest crossings.

Structural Design Differences

Cantilever bridges utilize projecting beams anchored only at one end, relying on counterbalancing forces within the structure to support loads, while suspension bridges employ cables suspended between towers to carry the deck through tension. Cantilever designs typically involve rigid trusses or girders extending from piers, providing strong resistance to bending moments, whereas suspension bridges depend on flexible cables that distribute weight to anchorages and towers, allowing longer spans. The structural behavior in cantilever bridges centers on compression and tension within the cantilever arms, contrasting with the primarily tensile forces in suspension bridge cables.

Materials Used in Construction

Cantilever bridges primarily use steel and reinforced concrete due to their strength and ability to resist tension and compression forces in the extended arms. Suspension bridges rely heavily on high-tensile steel cables to support the deck, along with steel or concrete towers that bear immense vertical loads. The choice of materials directly influences each bridge type's load-bearing capacity, durability, and suitability for different span lengths.

Load Distribution and Support Mechanisms

Cantilever bridges transfer loads through rigid arms anchored at only one end, effectively distributing weight to the supporting piers via tension in the upper chords and compression in the lower chords. Suspension bridges carry loads by suspending the deck from cables stretched between towers, with tension forces in the main cables transferred to anchored supports at both ends. The structural efficiency of cantilever bridges lies in their ability to handle heavy loads with fewer piers, while suspension bridges excel in spanning longer distances through flexible load distribution across cables and towers.

Span Length Capabilities

Cantilever bridges typically span distances between 150 to 1,500 feet, making them suitable for medium-length crossings over rivers or valleys. Suspension bridges can achieve much longer spans, often exceeding 2,000 feet and reaching over 7,000 feet in major examples like the Akashi Kaikyo Bridge. The superior span length capability of suspension bridges makes them ideal for wide bodies of water and challenging geographic locations requiring minimal support piers.

Applications and Suitability

Cantilever bridges are ideal for medium-span crossings where solid anchorages are available, commonly used in railway and highway overpasses due to their ability to handle heavy loads and resist bending moments. Suspension bridges excel in long-span applications such as crossing wide rivers and deep valleys, offering superior flexibility and capacity to accommodate dynamic loads like wind and earthquakes. Both bridge types cater to specific site conditions and structural requirements, with cantilever bridges favoring rigid support points and suspension bridges suited for expansive distances requiring minimal piers.

Construction Techniques and Challenges

Cantilever bridges rely on balanced cantilever construction, where segments extend horizontally from piers without supporting falsework, demanding precise counterbalancing to maintain stability during assembly. Suspension bridges use cables anchored at both ends, with main cables draped over towers supporting the deck via vertical suspenders, requiring extensive cable spinning and anchorage work to handle tensile forces. Construction challenges for cantilever bridges involve managing cantilever deflections and moments, while suspension bridges face complexities in cable installation, tower erection, and ensuring aerodynamic stability under dynamic loads.

Cost Analysis and Budget Considerations

Cantilever bridges typically incur lower initial construction costs compared to suspension bridges due to simpler materials and engineering requirements. Suspension bridges demand higher budgets for cables, towers, and anchorages, as well as more complex labor and maintenance costs over time. Cost analysis must factor in project scale, site conditions, and long-term durability to determine the most economical bridge type.

Maintenance and Durability

Cantilever bridges require regular inspection and maintenance of their joints and cantilever arms to prevent stress corrosion and metal fatigue, ensuring longevity in harsh conditions. Suspension bridges demand vigilant upkeep of cables, anchorages, and deck components to mitigate corrosion and cable fatigue, which are critical for maintaining structural integrity over time. Both bridge types benefit from advanced materials and protective coatings to enhance durability and reduce long-term maintenance costs.

Notable Examples Around the World

The Forth Bridge in Scotland exemplifies cantilever bridge design with its massive steel truss structure, while the Golden Gate Bridge in San Francisco represents iconic suspension bridge engineering through its long main span supported by cables. Cantilever bridges like the Quebec Bridge in Canada demonstrate exceptional load-bearing capacity for heavy rail traffic. Suspension bridges such as the Akashi Kaikyo Bridge in Japan hold the record for the longest central span, showcasing advanced cable technology for flexibility and strength.

Dead load distribution

Cantilever bridges distribute dead load primarily through tension in the top chords and compression in the bottom chords of their cantilever arms, while suspension bridges transfer dead load via cables in tension to towers and anchorages.

Main span length

Suspension bridges achieve longer main span lengths, often exceeding 2,000 meters, compared to cantilever bridges, which typically max out around 500 meters.

Tension and compression zones

Cantilever bridges experience compression in the anchored arms and tension in the suspended span, while suspension bridges primarily have tension in the main cables and compression in the towers.

Pylon tower geometry

Cantilever bridges feature rigid, triangular-shaped pylon towers optimized for load distribution, while suspension bridges utilize tall, slender, and often A-shaped or H-shaped pylon towers designed to anchor main cables and maximize tensile strength.

Deck anchorage system

Cantilever bridges secure the deck through balanced cantilever arms anchored to piers, while suspension bridges use cables anchored into massive ground-based anchorages to hold the deck suspended.

Moment-resisting structure

Cantilever bridges use moment-resisting structures with rigid connections to support loads through balanced cantilevers, while suspension bridges rely primarily on flexible cables and towers to transfer loads without significant moment resistance in the deck.

Cable-stayed interaction

Cable-stayed bridges transfer loads directly from the deck to towers through angled cables, whereas cantilever bridges rely on balanced arms extending from supports, making cable-stayed designs more efficient for longer spans with reduced material usage.

Expansion joint design

Expansion joint design in cantilever bridges typically involves fixed bearings and sliding joints to accommodate thermal movement, whereas suspension bridges utilize flexible expansion joints combined with elastomeric bearings to manage larger dynamic displacements.

Vibration damping methods

Cantilever bridges primarily use tuned mass dampers and viscoelastic dampers to reduce vibrations, whereas suspension bridges employ aerodynamic fairings, tuned mass dampers, and viscous fluid dampers for effective vibration damping.

Construction staging sequence

Cantilever bridge construction involves sequential segment erection from piers using balanced cantilever methods, while suspension bridge construction stages include erecting towers, installing main cables, and suspending the deck in sections.

cantilever bridge vs suspension bridge Infographic

njnir.com

njnir.com