Microtunneling offers a trenchless solution that minimizes surface disruption, making it ideal for urban areas with limited space and sensitive environments. In contrast, open-cut excavation involves extensive digging and surface disruption, often resulting in longer project timelines and increased impact on traffic and nearby infrastructure. Choosing between microtunneling and open-cut excavation depends on factors like soil conditions, project scale, and environmental constraints.

Table of Comparison

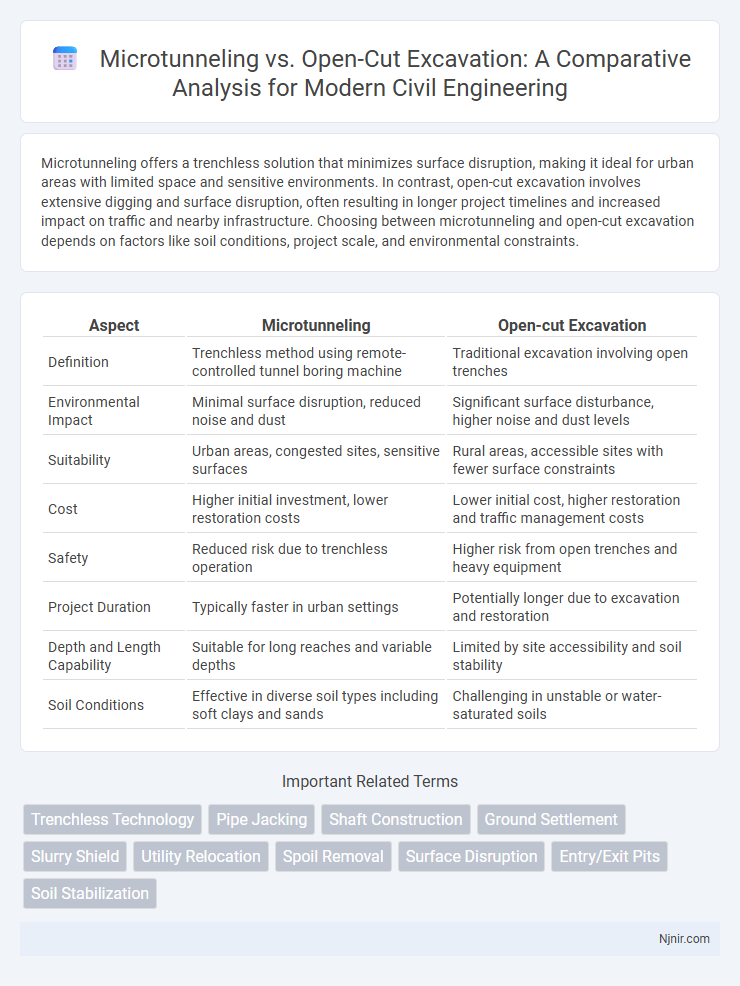

| Aspect | Microtunneling | Open-cut Excavation |

|---|---|---|

| Definition | Trenchless method using remote-controlled tunnel boring machine | Traditional excavation involving open trenches |

| Environmental Impact | Minimal surface disruption, reduced noise and dust | Significant surface disturbance, higher noise and dust levels |

| Suitability | Urban areas, congested sites, sensitive surfaces | Rural areas, accessible sites with fewer surface constraints |

| Cost | Higher initial investment, lower restoration costs | Lower initial cost, higher restoration and traffic management costs |

| Safety | Reduced risk due to trenchless operation | Higher risk from open trenches and heavy equipment |

| Project Duration | Typically faster in urban settings | Potentially longer due to excavation and restoration |

| Depth and Length Capability | Suitable for long reaches and variable depths | Limited by site accessibility and soil stability |

| Soil Conditions | Effective in diverse soil types including soft clays and sands | Challenging in unstable or water-saturated soils |

Overview of Microtunneling and Open-cut Excavation

Microtunneling is a trenchless construction method that uses remote-controlled, guided pipe jacking to install underground pipelines with minimal surface disruption, ideal for urban or environmentally sensitive areas. Open-cut excavation involves traditional trench digging, offering direct access for pipeline installation but causing significant surface disturbance and longer restoration times. The choice between microtunneling and open-cut excavation depends on project-specific factors such as soil conditions, project length, surface impact tolerance, and cost considerations.

Key Applications in Civil Engineering Projects

Microtunneling excels in civil engineering projects requiring minimal surface disruption, such as urban utility installations and water or sewage pipelines beneath highways or rivers. Open-cut excavation remains preferred for shallow depth infrastructure works like road construction, drainage systems, and foundation laying where surface restoration is feasible. Selecting between microtunneling and open-cut excavation depends on project constraints including environmental impact, urban density, and soil conditions.

Technical Differences between Microtunneling and Open-cut Methods

Microtunneling employs remote-controlled, guided boring machines to create underground tunnels with minimal surface disruption, while open-cut excavation involves digging large trenches from the surface for pipe installation. Microtunneling allows precise, continuous pipe installation at controlled depths and gradients, reducing soil settlement and surface restoration needs compared to open-cut methods. The open-cut approach is technically straightforward but requires extensive surface excavation, traffic disruption, and higher restoration costs.

Construction Process Comparison

Microtunneling utilizes a remote-controlled, guided boring machine to create underground tunnels with minimal surface disruption, offering precise alignment and reduced environmental impact compared to open-cut excavation. Open-cut excavation involves digging a large trench from the surface, allowing direct access but causing significant surface disturbance, higher restoration costs, and extended project timelines. The microtunneling process is ideal for urban areas and sensitive environments due to its trenchless nature, while open-cut suits projects where surface disruption is permissible and cost constraints favor traditional excavation methods.

Environmental Impact: Microtunneling vs Open-cut Excavation

Microtunneling significantly reduces surface disruption compared to open-cut excavation, minimizing habitat destruction and soil erosion. The trenchless nature of microtunneling lowers air and noise pollution by limiting heavy machinery usage and truck traffic. Conversely, open-cut excavation often results in extensive land disturbance, increased sediment runoff, and higher emissions from prolonged construction activities.

Cost Analysis and Budget Considerations

Microtunneling typically incurs higher upfront costs due to specialized equipment and technology, but it offers significant savings by minimizing surface disruption and restoration expenses compared to open-cut excavation. Open-cut excavation often involves lower initial machinery costs but can significantly increase total project expenses through extended traffic management, environmental remediation, and longer restoration periods. Budget considerations must weigh the trade-offs between the higher capital investment of microtunneling and the potential indirect costs and socio-environmental impacts associated with open-cut methods.

Safety Aspects in Both Excavation Methods

Microtunneling significantly enhances worker safety by minimizing surface disruption and reducing the risk of trench collapses common in open-cut excavation. Unlike open-cut excavation, which exposes workers to hazards like falling debris and heavy machinery in open trenches, microtunneling operates remotely underground, limiting direct human exposure to unstable soil conditions. Safety protocols in microtunneling also benefit from automated guidance systems and pressurized tunnel environments, further decreasing accident rates compared to traditional open-cut methods.

Surface Disruption and Community Impact

Microtunneling significantly reduces surface disruption compared to open-cut excavation by minimizing the need for large trenches, preserving roadways, sidewalks, and landscapes. This trenchless technology limits noise, dust, and traffic interruptions, leading to lower negative impacts on local communities and businesses. Conversely, open-cut excavation often causes extended surface damage, traffic detours, and noise pollution, resulting in greater community inconvenience and longer recovery times for affected areas.

Project Timeline and Efficiency Evaluation

Microtunneling projects typically demonstrate shorter timelines and higher efficiency compared to open-cut excavation, especially in urban areas where surface disruption must be minimized. The trenchless technology of microtunneling allows continuous excavation and pipe installation with minimal interference to existing infrastructure, leading to faster project completion. Open-cut excavation often faces delays due to extensive surface restoration and traffic management, reducing overall project efficiency.

Selection Criteria: Choosing the Right Excavation Method

Microtunneling offers precise control, minimal surface disruption, and reduced environmental impact, making it ideal for urban areas with limited space and sensitive infrastructure. Open-cut excavation is generally preferred for projects requiring lower initial costs and simpler implementation in less congested or rural sites with straightforward soil conditions. Key selection criteria include project scale, soil type, groundwater conditions, surface access constraints, and budget considerations to determine the most efficient and cost-effective excavation method.

Trenchless Technology

Microtunneling, a trenchless technology, minimizes surface disruption and reduces environmental impact compared to traditional open-cut excavation for underground utility installations.

Pipe Jacking

Microtunneling optimizes precision and minimizes surface disruption compared to open-cut excavation by using pipe jacking techniques to install pipelines underground with remote-controlled guidance systems.

Shaft Construction

Shaft construction in microtunneling requires smaller, more precise excavation methods with minimal surface disruption, while open-cut excavation involves large-scale surface digging and extensive soil removal for shaft installation.

Ground Settlement

Microtunneling significantly minimizes ground settlement compared to open-cut excavation by employing trenchless technology that reduces surface disruption and soil displacement.

Slurry Shield

Microtunneling with slurry shield technology offers precise, low-impact underground pipe installation compared to disruptive, surface-disturbing open-cut excavation methods.

Utility Relocation

Microtunneling offers precise utility relocation with minimal surface disruption compared to extensive excavation and restoration required in open-cut methods.

Spoil Removal

Microtunneling minimizes spoil removal volume and surface disruption by transporting excavated material through sealed pipes, whereas open-cut excavation generates larger spoil piles requiring extensive hauling and surface restoration.

Surface Disruption

Microtunneling minimizes surface disruption compared to open-cut excavation by utilizing remote-controlled boring machines to install underground pipelines without extensive surface excavation.

Entry/Exit Pits

Microtunneling requires smaller, precisely engineered entry and exit pits compared to the larger, more disruptive excavation pits needed for open-cut methods, minimizing surface impact and reducing restoration costs.

Soil Stabilization

Microtunneling provides superior soil stabilization compared to open-cut excavation by minimizing ground disturbance and preventing soil erosion during underground pipeline installation.

Microtunneling vs Open-cut Excavation Infographic

njnir.com

njnir.com