Cross-laminated timber (CLT) offers superior dimensional stability and strength due to its multi-layered cross-grain construction compared to glulam beams, which consist of parallel-laminated layers. CLT panels provide enhanced shear resistance and load distribution, making them ideal for floor and wall systems, while glulam beams excel in long-span applications requiring high bending strength. Both materials contribute to sustainable construction practices, but CLT's prefabricated nature often results in faster installation and reduced labor costs on-site.

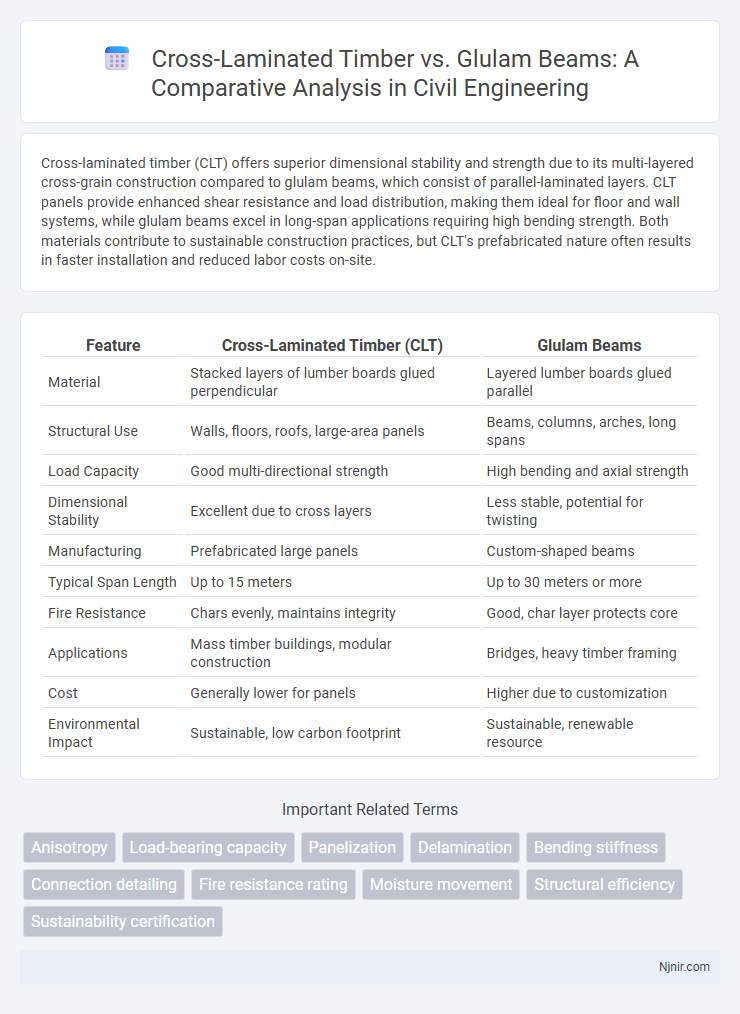

Table of Comparison

| Feature | Cross-Laminated Timber (CLT) | Glulam Beams |

|---|---|---|

| Material | Stacked layers of lumber boards glued perpendicular | Layered lumber boards glued parallel |

| Structural Use | Walls, floors, roofs, large-area panels | Beams, columns, arches, long spans |

| Load Capacity | Good multi-directional strength | High bending and axial strength |

| Dimensional Stability | Excellent due to cross layers | Less stable, potential for twisting |

| Manufacturing | Prefabricated large panels | Custom-shaped beams |

| Typical Span Length | Up to 15 meters | Up to 30 meters or more |

| Fire Resistance | Chars evenly, maintains integrity | Good, char layer protects core |

| Applications | Mass timber buildings, modular construction | Bridges, heavy timber framing |

| Cost | Generally lower for panels | Higher due to customization |

| Environmental Impact | Sustainable, low carbon footprint | Sustainable, renewable resource |

Introduction to Engineered Wood: CLT vs Glulam

Cross-laminated timber (CLT) and glulam beams are key engineered wood products widely used in modern construction for their strength and sustainability. CLT consists of multiple layers of lumber boards stacked crosswise and glued, offering exceptional dimensional stability and load distribution, while glulam beams are composed of several layers of laminated timber bonded parallel to each other, providing high flexural strength and versatility in shapes. Both materials optimize wood performance through adhesive lamination but cater to different structural needs, with CLT favored for large panel applications and glulam ideal for beams and columns.

Material Composition and Manufacturing Processes

Cross-laminated timber (CLT) consists of multiple layers of lumber boards stacked crosswise and bonded with structural adhesives, creating a panel with high dimensional stability and load-bearing capacity. Glulam beams are fabricated by gluing together several layers of kiln-dried lumber with the grain oriented parallel, resulting in strong, flexible structural members ideal for long spans. Both manufacturing processes involve precision drying, surface planing, adhesive application, and pressing, but CLT panels emphasize orthogonal lamination for multi-directional strength whereas glulam beams utilize unidirectional lamination optimized for bending resistance.

Structural Performance and Load-Bearing Capacity

Cross-laminated timber (CLT) offers superior dimensional stability and multi-directional strength due to its layered perpendicular grain configuration, enhancing overall structural performance. Glulam beams provide exceptional load-bearing capacity with high tensile strength along the grain, making them ideal for long-span applications and heavy loads. In terms of structural performance, CLT excels in shear resistance and stiffness across multiple axes, while glulam is optimized for bending and compressive forces primarily along the beam length.

Design Flexibility and Architectural Applications

Cross-laminated timber (CLT) offers superior design flexibility due to its panelized structure, enabling large spans and complex shapes ideal for walls, floors, and roofs in modern architectural applications. Glulam beams provide strength and aesthetic appeal with customizable curves and depths, commonly used in exposed beam designs and heavy timber framing. Both materials support sustainable construction, but CLT excels in modular construction workflows while glulam is preferred for intricate, load-bearing beam work.

Durability and Fire Resistance Characteristics

Cross-laminated timber (CLT) offers enhanced fire resistance due to its thick, layered construction that chars on the surface, slowing combustion and maintaining structural integrity longer than glulam beams. Glulam beams, composed of laminated wood layers bonded with adhesives, exhibit excellent strength but may have reduced fire resistance depending on adhesive type and manufacturing quality. Both materials can achieve durability through treatments and design, yet CLT generally provides superior performance in resisting fire damage over extended exposure periods.

Sustainability and Environmental Impact

Cross-laminated timber (CLT) and glulam beams both offer sustainable building solutions by utilizing engineered wood that sequesters carbon and reduces reliance on concrete and steel. CLT panels provide excellent material efficiency through layered construction, maximizing wood use and minimizing waste, while glulam beams enable long spans and structural strength with less resource consumption compared to traditional timber. Both materials promote lower embodied energy and improved lifecycle benefits, significantly reducing greenhouse gas emissions in construction projects.

Cost Comparison and Economic Considerations

Cross-laminated timber (CLT) generally offers lower material costs compared to glulam beams due to its panelized production, reducing waste and labor expenses. Glulam beams often involve higher upfront investment because of their tailored, structural-grade lamination process, which enhances load-bearing capacity but increases fabrication costs. Economic considerations highlight that CLT is more cost-effective for large-scale floor and wall applications, while glulam is preferred for long-span or heavy-load structures where performance justifies the premium.

Installation Methods and Construction Speed

Cross-laminated timber (CLT) panels are prefabricated in large, flat sections that enable rapid on-site assembly through crane placement and bolted connections, significantly reducing installation time compared to traditional methods. Glulam beams require more precise, individual placement and fastening, often involving cranes and specialized labor, which can extend the construction schedule, especially for complex geometries. The modular nature of CLT supports faster construction speed, while glulam's flexibility offers tailored design but demands more intricate installation processes.

Building Codes and Compliance Standards

Cross-laminated timber (CLT) and glulam beams must meet rigorous building codes and compliance standards to ensure structural safety and durability in construction. CLT panels are increasingly recognized under modern building codes such as the International Building Code (IBC) and the Eurocode, often requiring specific fire resistance, moisture protection, and load-bearing verifications. Glulam beams, with established use in heavy timber construction, conform to standards like ANSI/AITC and ASTM, emphasizing dimensional stability, mechanical performance, and engineered wood grading requirements.

Case Studies: Real-World Projects Using CLT and Glulam

Case studies of real-world projects demonstrate the distinct advantages of cross-laminated timber (CLT) and glulam beams in modern construction. CLT has been effectively used in high-rise buildings such as the 18-story Brock Commons Tallwood House in Vancouver, showcasing its strength, fire resistance, and rapid assembly. Meanwhile, glulam beams are showcased in structures like the Forsyth Barr Stadium in New Zealand, where their tensile strength and aesthetic appeal provide long-span support and architectural beauty.

Anisotropy

Cross-laminated timber (CLT) exhibits reduced anisotropy due to its perpendicular layering of wood panels, while glulam beams display greater anisotropy as they are composed of unidirectionally laminated wood laminations.

Load-bearing capacity

Cross-laminated timber (CLT) offers superior load-bearing capacity across multiple directions due to its layered crosswise structure, while glulam beams provide higher load-bearing strength primarily along their longitudinal axis, making CLT better for multi-directional loads and glulam optimal for linear support applications.

Panelization

Cross-laminated timber (CLT) panels offer superior panelization with multi-layered, cross-oriented wood panels ideal for large-scale, prefabricated wall and floor systems, while glulam beams provide strong, flexible laminated wood beams primarily used for structural support in beams and columns.

Delamination

Cross-laminated timber exhibits superior resistance to delamination compared to glulam beams due to its crosswise laminated layers that enhance structural integrity and moisture resistance.

Bending stiffness

Cross-laminated timber exhibits higher bending stiffness than glulam beams due to its multilayered, perpendicular grain orientation that enhances structural rigidity.

Connection detailing

Cross-laminated timber offers superior dimensional stability and uniform load distribution in connection detailing compared to glulam beams, which require careful consideration of laminated layer orientation for joint strength and stiffness.

Fire resistance rating

Cross-laminated timber typically offers a higher fire resistance rating than glulam beams due to its thicker, layered construction that chars more slowly and maintains structural integrity longer under fire exposure.

Moisture movement

Cross-laminated timber exhibits more uniform moisture movement due to its crosswise layering, while glulam beams, composed of parallel laminations, experience greater dimensional changes along the grain, affecting their stability in humid environments.

Structural efficiency

Cross-laminated timber (CLT) offers superior structural efficiency through multidirectional strength and stiffness compared to glulam beams, which provide high strength primarily along a single axis.

Sustainability certification

Cross-laminated timber (CLT) and glulam beams both achieve sustainability certification through standards like FSC and PEFC, with CLT often preferred for its superior carbon sequestration and engineered efficiency in eco-friendly construction.

Cross-laminated timber vs glulam beams Infographic

njnir.com

njnir.com