Steel fiber reinforced concrete offers superior tensile strength and impact resistance compared to glass fiber reinforced concrete. The steel fibers enhance crack control and durability, making it ideal for heavy-load structures and industrial applications. Glass fiber reinforced concrete provides better corrosion resistance and improved flexural strength, suited for architectural elements and environments exposed to moisture.

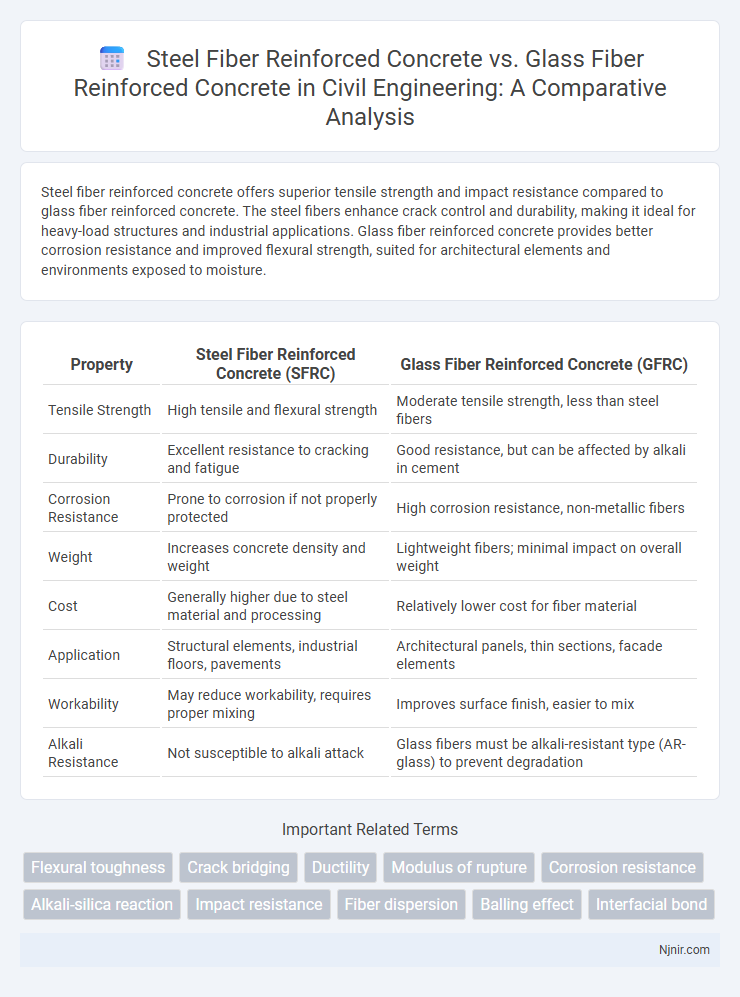

Table of Comparison

| Property | Steel Fiber Reinforced Concrete (SFRC) | Glass Fiber Reinforced Concrete (GFRC) |

|---|---|---|

| Tensile Strength | High tensile and flexural strength | Moderate tensile strength, less than steel fibers |

| Durability | Excellent resistance to cracking and fatigue | Good resistance, but can be affected by alkali in cement |

| Corrosion Resistance | Prone to corrosion if not properly protected | High corrosion resistance, non-metallic fibers |

| Weight | Increases concrete density and weight | Lightweight fibers; minimal impact on overall weight |

| Cost | Generally higher due to steel material and processing | Relatively lower cost for fiber material |

| Application | Structural elements, industrial floors, pavements | Architectural panels, thin sections, facade elements |

| Workability | May reduce workability, requires proper mixing | Improves surface finish, easier to mix |

| Alkali Resistance | Not susceptible to alkali attack | Glass fibers must be alkali-resistant type (AR-glass) to prevent degradation |

Introduction to Fiber Reinforced Concrete

Fiber reinforced concrete (FRC) enhances traditional concrete by integrating discrete fibers like steel or glass to improve tensile strength, ductility, and crack resistance. Steel fiber reinforced concrete (SFRC) offers superior load-bearing capacity and impact resistance due to the high tensile strength and stiffness of steel fibers. Glass fiber reinforced concrete (GFRC) provides excellent corrosion resistance and aesthetic versatility, making it ideal for architectural applications and thin, lightweight panels.

Composition of Steel and Glass Fiber Reinforced Concrete

Steel fiber reinforced concrete (SFRC) contains discrete steel fibers typically made from carbon steel with lengths ranging from 13 to 50 mm and diameters of 0.2 to 1 mm, which provide enhanced tensile strength and crack resistance. Glass fiber reinforced concrete (GFRC) incorporates alkali-resistant glass fibers usually measuring 12 to 18 mm in length with diameters around 13 microns, resulting in improved flexural strength and reduced permeability without significantly increasing weight. The differing fiber compositions influence mechanical properties, durability, and applications; steel fibers offer superior impact resistance while glass fibers excel in corrosion resistance and aesthetic versatility.

Mechanical Properties Comparison

Steel fiber reinforced concrete (SFRC) exhibits superior tensile strength and impact resistance compared to glass fiber reinforced concrete (GFRC), due to the higher modulus of elasticity and ductility of steel fibers. GFRC offers enhanced flexural strength and greater resistance to corrosion, making it suitable for environments exposed to moisture and chemical agents. Both materials improve concrete toughness, but SFRC typically outperforms GFRC in load-bearing capacity and abrasion resistance.

Durability and Longevity

Steel fiber reinforced concrete (SFRC) offers superior durability and longevity due to its high tensile strength and excellent crack resistance, making it ideal for heavy-duty applications subject to mechanical stress and impact. Glass fiber reinforced concrete (GFRC) provides enhanced resistance to corrosion, alkali environments, and weathering, contributing to its longevity in architectural and exterior applications where chemical exposure is prevalent. Both materials significantly improve the lifespan of concrete structures, with SFRC excelling in structural durability and GFRC excelling in environmental resistance.

Flexural and Tensile Strength Performance

Steel fiber reinforced concrete (SFRC) exhibits significantly higher flexural strength due to the superior tensile modulus and bonding ability of steel fibers, which enhance crack resistance and load distribution. Glass fiber reinforced concrete (GFRC) provides improved tensile strength and crack control compared to plain concrete but generally falls short of SFRC in flexural performance due to lower fiber stiffness. The optimized fiber orientation and volume fraction in SFRC lead to enhanced post-crack ductility and toughness, making it preferable for applications demanding high flexural and tensile strength.

Applications in Civil Engineering Projects

Steel fiber reinforced concrete (SFRC) is extensively used in heavy-duty civil engineering projects such as bridge decks, industrial floors, and tunnel linings due to its superior tensile strength and crack resistance. Glass fiber reinforced concrete (GFRC) finds applications in architectural facades, cladding panels, and decorative elements where lightweight, high durability, and corrosion resistance are essential. Both materials enhance structural integrity, but SFRC is favored for load-bearing infrastructure while GFRC excels in aesthetic and non-structural components.

Workability and Mixing Considerations

Steel fiber reinforced concrete (SFRC) typically exhibits reduced workability due to the density and stiffness of steel fibers, requiring adjustments such as increased water content or superplasticizers to ensure proper mixing and placement. In contrast, glass fiber reinforced concrete (GFRC) offers better workability because glass fibers are lighter and finer, allowing easier dispersion and reduced risk of fiber balling during mixing. Optimizing fiber volume, fiber type, and mixing sequence is crucial in both SFRC and GFRC to achieve uniform fiber distribution and maintain desired workability.

Cost Analysis and Economic Viability

Steel fiber reinforced concrete (SFRC) typically incurs higher initial material costs compared to glass fiber reinforced concrete (GFRC) due to the price of steel fibers and their incorporation process. However, SFRC offers superior tensile strength and durability, potentially reducing long-term maintenance and repair expenses, enhancing economic viability in structural applications. GFRC provides a cost-effective solution for non-structural or decorative elements, leveraging lower fiber costs and ease of handling while delivering adequate performance for facade panels and architectural finishes.

Environmental Impact and Sustainability

Steel fiber reinforced concrete (SFRC) demonstrates a higher environmental footprint due to energy-intensive steel production and associated carbon emissions, whereas glass fiber reinforced concrete (GFRC) offers improved sustainability by utilizing recycled glass fibers and lower embodied energy materials. Life cycle assessments indicate GFRC reduces landfill waste and energy consumption during manufacturing compared to SFRC, enhancing its eco-friendly profile. Both materials contribute to structural durability, but GFRC's lightweight nature and recyclability position it as a more sustainable choice in green construction practices.

Selection Guidelines and Recommendations

Steel fiber reinforced concrete (SFRC) is recommended for applications requiring high tensile strength and impact resistance, such as industrial floors and bridge decks, due to its superior load-bearing capacity and crack control. Glass fiber reinforced concrete (GFRC) is better suited for architectural panels and decorative elements where lightweight, corrosion resistance, and high tensile strength at a lower cost are priorities. Selection guidelines emphasize evaluating environmental exposure, structural requirements, and cost-effectiveness to determine the appropriate fiber type for enhanced durability and performance.

Flexural toughness

Steel fiber reinforced concrete exhibits significantly higher flexural toughness than glass fiber reinforced concrete due to steel fibers' superior tensile strength and energy absorption capacity.

Crack bridging

Steel fiber reinforced concrete exhibits superior crack bridging capabilities compared to glass fiber reinforced concrete due to its higher tensile strength and ductility, leading to enhanced crack control and structural durability.

Ductility

Steel fiber reinforced concrete exhibits significantly higher ductility compared to glass fiber reinforced concrete due to the superior tensile strength and crack-bridging capacity of steel fibers.

Modulus of rupture

Steel fiber reinforced concrete exhibits a higher modulus of rupture compared to glass fiber reinforced concrete due to improved tensile strength and crack resistance.

Corrosion resistance

Steel fiber reinforced concrete exhibits lower corrosion resistance compared to glass fiber reinforced concrete due to the susceptibility of steel fibers to rust in moist environments.

Alkali-silica reaction

Steel fiber reinforced concrete demonstrates superior resistance to Alkali-silica reaction compared to glass fiber reinforced concrete due to its enhanced crack-bridging capabilities and reduced permeability.

Impact resistance

Steel fiber reinforced concrete exhibits significantly higher impact resistance than glass fiber reinforced concrete due to its superior tensile strength and energy absorption properties.

Fiber dispersion

Steel fiber reinforced concrete exhibits superior fiber dispersion due to its heavier and stiffer fibers, whereas glass fiber reinforced concrete often faces challenges with uniform fiber distribution because of fiber clumping and lower stiffness.

Balling effect

Steel fiber reinforced concrete exhibits significantly less balling effect compared to glass fiber reinforced concrete, resulting in improved fiber dispersion and enhanced mechanical properties.

Interfacial bond

Steel fiber reinforced concrete exhibits a stronger interfacial bond due to mechanical interlocking and higher tensile strength compared to the typically weaker chemical adhesion in glass fiber reinforced concrete.

Steel fiber reinforced concrete vs Glass fiber reinforced concrete Infographic

njnir.com

njnir.com