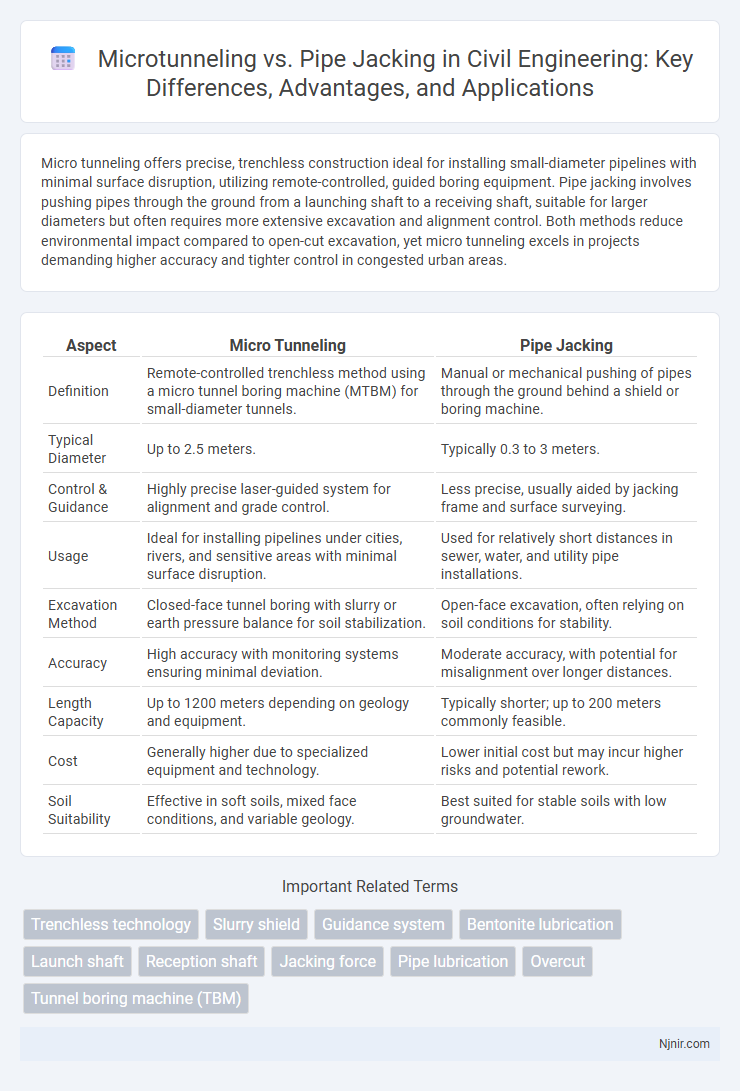

Micro tunneling offers precise, trenchless construction ideal for installing small-diameter pipelines with minimal surface disruption, utilizing remote-controlled, guided boring equipment. Pipe jacking involves pushing pipes through the ground from a launching shaft to a receiving shaft, suitable for larger diameters but often requires more extensive excavation and alignment control. Both methods reduce environmental impact compared to open-cut excavation, yet micro tunneling excels in projects demanding higher accuracy and tighter control in congested urban areas.

Table of Comparison

| Aspect | Micro Tunneling | Pipe Jacking |

|---|---|---|

| Definition | Remote-controlled trenchless method using a micro tunnel boring machine (MTBM) for small-diameter tunnels. | Manual or mechanical pushing of pipes through the ground behind a shield or boring machine. |

| Typical Diameter | Up to 2.5 meters. | Typically 0.3 to 3 meters. |

| Control & Guidance | Highly precise laser-guided system for alignment and grade control. | Less precise, usually aided by jacking frame and surface surveying. |

| Usage | Ideal for installing pipelines under cities, rivers, and sensitive areas with minimal surface disruption. | Used for relatively short distances in sewer, water, and utility pipe installations. |

| Excavation Method | Closed-face tunnel boring with slurry or earth pressure balance for soil stabilization. | Open-face excavation, often relying on soil conditions for stability. |

| Accuracy | High accuracy with monitoring systems ensuring minimal deviation. | Moderate accuracy, with potential for misalignment over longer distances. |

| Length Capacity | Up to 1200 meters depending on geology and equipment. | Typically shorter; up to 200 meters commonly feasible. |

| Cost | Generally higher due to specialized equipment and technology. | Lower initial cost but may incur higher risks and potential rework. |

| Soil Suitability | Effective in soft soils, mixed face conditions, and variable geology. | Best suited for stable soils with low groundwater. |

Introduction to Trenchless Technologies

Trenchless technologies, including micro tunneling and pipe jacking, offer advanced solutions for installing underground pipelines with minimal surface disruption. Micro tunneling utilizes remote-controlled, precision-guided machines ideal for small diameter, high-accuracy projects, while pipe jacking involves hydraulic jacks pushing pipes into place through a pre-excavated tunnel, commonly used for larger diameter pipelines. These methods significantly reduce environmental impact, traffic interference, and excavation costs compared to traditional open-cut techniques.

Overview of Micro Tunneling

Micro tunneling is a trenchless construction method that uses a remote-controlled, guided boring machine to install pipelines with minimal surface disruption. It offers precise control and is ideal for installing pipes in urban areas or challenging terrains where traditional open-cut methods are impractical. Compared to pipe jacking, micro tunneling typically requires advanced guidance systems and allows for smaller diameter pipelines with reduced risk of ground settlement.

Overview of Pipe Jacking

Pipe jacking is a trenchless construction method used to install underground pipelines by hydraulically pushing pipes through the soil from a launch shaft to a reception shaft. This technique efficiently minimizes surface disruption, making it ideal for urban areas and projects requiring precise alignment and gradient control. It typically handles larger diameter pipes compared to micro tunneling, making it suitable for water, sewer, and utility infrastructure installations.

Key Differences Between Micro Tunneling and Pipe Jacking

Micro tunneling employs remote-controlled, guided tunneling machines ideal for installing small-diameter pipelines with minimal surface disruption, whereas pipe jacking uses hydraulic jacks to push prefabricated pipes through the soil, often suited for larger diameters. Precision in micro tunneling is achieved through laser guidance systems, enabling accurate alignment and reduced risk of ground settlement, while pipe jacking relies more on manual surveying and alignment techniques. The selection between micro tunneling and pipe jacking depends on project scale, soil conditions, pipeline diameter, and surface impact requirements.

Equipment and Machinery Used

Micro tunneling employs remotely controlled, laser-guided tunnel boring machines (TBMs) specifically designed for small-diameter pipelines, featuring slurry or pressurized face systems for soil stabilization. Pipe jacking uses hydraulic jacks to push prefabricated pipe sections through the ground, typically paired with a shield to support the excavation face and often relies on manual guidance or simpler mechanical steering. The precision and automation level in micro tunneling equipment surpasses the more mechanical and labor-intensive setup of pipe jacking machinery.

Suitable Soil Conditions and Applications

Micro tunneling excels in variable soil conditions including clay, silt, sand, and mixed ground, making it ideal for urban environments with limited space and sensitive surface infrastructure. Pipe jacking performs best in stable, uniform soils such as firm clay or sandstone, suitable for shorter distances and projects requiring less precision. Both methods serve utilities installation, but micro tunneling is preferred for longer, complex alignments while pipe jacking is cost-effective for straight, shallow pipelines.

Installation Accuracy and Tolerances

Micro tunneling and pipe jacking both offer precise installation methods for underground pipelines, with micro tunneling utilizing remote-controlled equipment to achieve higher accuracy. Micro tunneling typically achieves tolerances of +-25 mm in alignment and elevation, making it ideal for projects requiring stringent precision. Pipe jacking, while still accurate, generally allows for tolerances around +-50 mm, suitable for larger diameter pipes where slight deviations are acceptable.

Cost Comparison and Project Economics

Micro tunneling typically incurs higher upfront costs due to advanced remote-controlled equipment and precision engineering, which suits projects requiring minimal surface disruption. Pipe jacking offers lower initial expenses by leveraging simpler excavation methods but may lead to increased costs if soil conditions necessitate frequent adjustments or repairs. Project economics favor micro tunneling in urban environments with strict surface constraints, while pipe jacking remains cost-effective for straightforward alignments and less sensitive sites.

Environmental Impact and Site Disruption

Micro tunneling generates less noise and vibration compared to pipe jacking, minimizing disturbance to surrounding ecosystems and urban areas. Its remote-controlled operations reduce the need for extensive excavation, leading to lower soil displacement and decreased risk of groundwater contamination. Pipe jacking, while effective for larger diameters, typically involves greater surface disruption, increased waste material, and elevated emissions from heavier machinery.

Selection Criteria for Civil Engineering Projects

Selection criteria for micro tunneling versus pipe jacking in civil engineering projects depend on factors such as ground conditions, project scale, and alignment complexity. Micro tunneling is preferred for smaller diameter installations requiring precise control in challenging soil or urban environments, while pipe jacking suits larger diameter pipes and less complex alignments. Cost efficiency, project duration, and minimal surface disruption also influence the decision between micro tunneling and pipe jacking methods.

Trenchless technology

Micro tunneling offers high-precision, remotely controlled trenchless technology ideal for installing small-diameter pipelines, while pipe jacking effectively facilitates larger-diameter pipe installation through hydraulic jacks without excavation.

Slurry shield

Slurry shield micro tunneling uses pressurized slurry to stabilize the tunnel face and transport excavated material, providing superior ground support compared to traditional pipe jacking methods without slurry.

Guidance system

Micro tunneling utilizes advanced remote-controlled guidance systems with laser and gyroscopic technology for precise alignment, whereas pipe jacking often relies on less sophisticated manual or basic mechanical steering methods.

Bentonite lubrication

Bentonite lubrication significantly enhances micro tunneling efficiency by reducing friction and stabilizing the tunnel face compared to traditional pipe jacking methods.

Launch shaft

The launch shaft for micro tunneling is typically smaller and designed for remote operation, while pipe jacking launch shafts are larger to accommodate manual installation and alignment of pipes.

Reception shaft

The reception shaft in micro tunneling is typically smaller and designed for precise alignment and extraction of the tunnel boring machine, while in pipe jacking it is larger to accommodate manual pipe installation and jacking operations.

Jacking force

Micro tunneling requires lower jacking force compared to pipe jacking due to its smaller diameter and automated guidance system.

Pipe lubrication

Pipe lubrication significantly reduces friction and wear during pipe jacking, enhancing borehole stability and ensuring smoother pipe advancement compared to micro tunneling.

Overcut

Micro tunneling typically achieves a smaller overcut range of 10-50 mm compared to pipe jacking, minimizing ground disturbance and improving alignment precision.

Tunnel boring machine (TBM)

Micro tunneling uses a remote-controlled Tunnel Boring Machine (TBM) for precise, small-diameter pipelines, while pipe jacking relies on manual or hydraulic pushing with less TBM integration.

micro tunneling vs pipe jacking Infographic

njnir.com

njnir.com