Pervious concrete offers superior load-bearing capacity and durability compared to porous asphalt, making it ideal for heavy traffic areas in civil engineering projects. Its interconnected void structure enhances stormwater infiltration and reduces runoff, while porous asphalt typically requires more frequent maintenance due to clogging and surface wear. Selecting pervious concrete improves long-term performance and sustainability in pavement design.

Table of Comparison

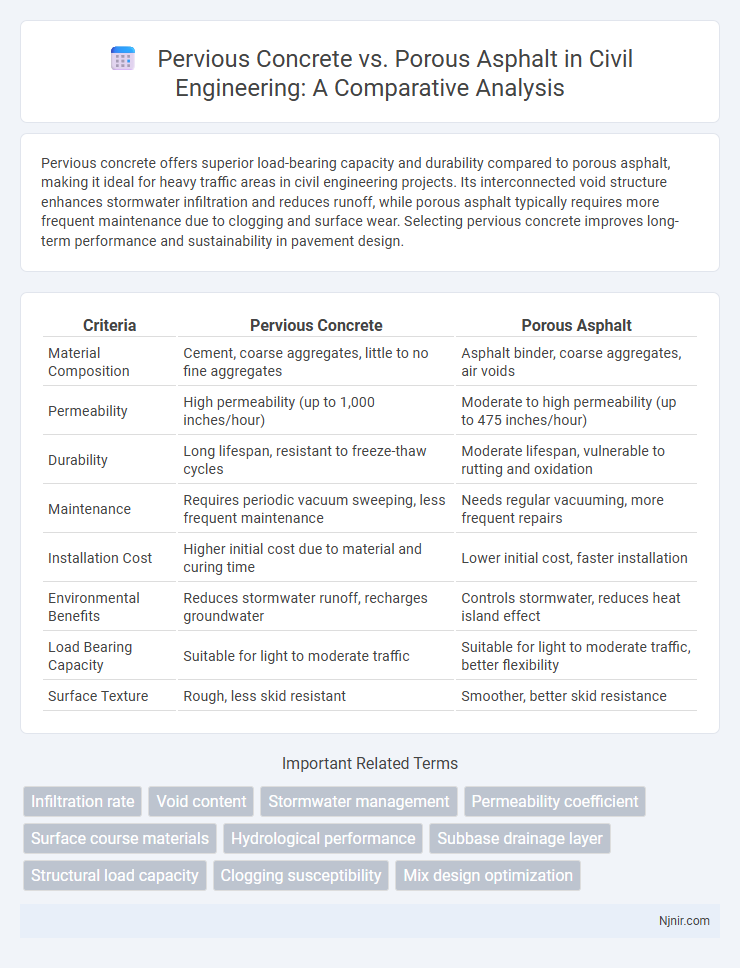

| Criteria | Pervious Concrete | Porous Asphalt |

|---|---|---|

| Material Composition | Cement, coarse aggregates, little to no fine aggregates | Asphalt binder, coarse aggregates, air voids |

| Permeability | High permeability (up to 1,000 inches/hour) | Moderate to high permeability (up to 475 inches/hour) |

| Durability | Long lifespan, resistant to freeze-thaw cycles | Moderate lifespan, vulnerable to rutting and oxidation |

| Maintenance | Requires periodic vacuum sweeping, less frequent maintenance | Needs regular vacuuming, more frequent repairs |

| Installation Cost | Higher initial cost due to material and curing time | Lower initial cost, faster installation |

| Environmental Benefits | Reduces stormwater runoff, recharges groundwater | Controls stormwater, reduces heat island effect |

| Load Bearing Capacity | Suitable for light to moderate traffic | Suitable for light to moderate traffic, better flexibility |

| Surface Texture | Rough, less skid resistant | Smoother, better skid resistance |

Introduction to Pervious Concrete and Porous Asphalt

Pervious concrete is a sustainable pavement material characterized by its high porosity, allowing water to infiltrate through its interconnected voids, thus reducing stormwater runoff and promoting groundwater recharge. Porous asphalt, similarly designed for permeability, consists of an open-graded aggregate structure bound by asphalt cement, enabling rapid water drainage and minimizing surface water accumulation. Both materials serve crucial roles in permeable pavement systems, contributing to effective stormwater management and urban heat island mitigation.

Material Composition and Structure

Pervious concrete consists of cement, coarse aggregates, and little to no fine aggregates, creating a porous matrix that allows water infiltration through interconnected voids. Porous asphalt is made from conventional asphalt binder mixed with coarse aggregates and minimal fine particles, resulting in a permeable pavement with voids between aggregate particles. The distinct material compositions and structural void networks of pervious concrete and porous asphalt determine their permeability, durability, and load-bearing capacities in stormwater management applications.

Permeability and Drainage Characteristics

Pervious concrete exhibits higher permeability rates, allowing water to pass through at approximately 200 to 1200 gallons per minute per square foot, promoting efficient groundwater recharge and reducing surface runoff. Porous asphalt also offers significant permeability, typically ranging from 150 to 500 gallons per minute per square foot, but may experience clogging faster than pervious concrete due to its organic binder composition. Both materials enhance drainage characteristics, yet pervious concrete provides longer-lasting structural integrity under heavy loads while maintaining superior water infiltration in urban stormwater management.

Strength and Durability Comparison

Pervious concrete exhibits higher compressive strength, typically ranging from 3,000 to 4,000 psi, compared to porous asphalt's lower strength of about 1,500 to 3,000 psi, making it more suitable for areas subject to heavy traffic loads. Durability of pervious concrete is enhanced by its rigid matrix, providing superior resistance to deformation and freeze-thaw cycles, while porous asphalt tends to deform under heavy loads and requires more frequent maintenance due to binder oxidation. Both materials facilitate stormwater infiltration, but pervious concrete's long-term structural integrity generally outperforms porous asphalt in applications demanding sustained strength and durability.

Environmental Benefits and Applications

Pervious concrete and porous asphalt both enhance stormwater management by promoting groundwater recharge and reducing runoff, significantly lowering urban heat island effects and water pollution. Pervious concrete offers higher structural strength and durability, making it ideal for parking lots and low-traffic pavements, while porous asphalt excels in flexibility and quick installation for roadways and bike paths. Both materials support sustainable infrastructure by improving water quality and mitigating flood risks in urban environments.

Installation Methods and Construction Practices

Pervious concrete installation requires careful mixing, placement, and curing to maintain its porous structure, typically involving low-slump concrete and controlled vibration. Porous asphalt installation involves laying a gap-graded asphalt mix with specialized rollers to avoid compressing voids, ensuring adequate permeability. Both materials demand precise subgrade preparation and drainage considerations to optimize their infiltration performance and longevity.

Maintenance Requirements and Longevity

Pervious concrete requires regular vacuum sweeping and occasional pressure washing to prevent clogging of its porous structure, maintaining optimal permeability and structural integrity over 15 to 30 years. Porous asphalt demands more frequent maintenance, including resealing and cleaning every 1 to 3 years to preserve drainage capacity, with an average lifespan of 7 to 15 years depending on traffic load and climate conditions. Proper maintenance of pervious concrete typically results in longer durability and sustained performance compared to porous asphalt, which is more susceptible to wear and environmental degradation.

Cost Considerations and Lifecycle Analysis

Pervious concrete typically presents higher initial installation costs than porous asphalt due to the need for specialized mixing and curing processes, but it offers lower maintenance expenses over time because of its durability and resistance to clogging. Porous asphalt requires more frequent maintenance, such as vacuum sweeping to prevent pore clogging, which can increase long-term operational costs despite its lower upfront price. Lifecycle analysis reveals that pervious concrete's longer lifespan and reduced maintenance interventions generally result in a more cost-effective solution over decades compared to porous asphalt's shorter service life and higher maintenance demands.

Performance in Different Climates

Pervious concrete maintains superior structural integrity in cold climates due to its resistance to freeze-thaw cycles and efficient water drainage, reducing surface ice formation. Porous asphalt excels in warm climates by providing rapid stormwater infiltration and flexibility, which helps mitigate rutting and heat-related damage. Both materials enhance urban water management but their performance varies significantly with temperature fluctuations and precipitation patterns.

Selection Guidelines for Civil Engineering Projects

Selection guidelines for civil engineering projects emphasize pervious concrete when enhanced durability and structural strength are critical, especially in high-traffic or load-bearing applications. Porous asphalt is favored for rapid water infiltration and flexibility, making it ideal for parking lots and low-speed roadways where drainage and noise reduction are priorities. Evaluating site-specific factors such as climate, soil permeability, maintenance requirements, and traffic load helps determine the optimal permeable pavement choice.

Infiltration rate

Pervious concrete typically exhibits an infiltration rate of 500 to 5,000 inches per hour, significantly higher than porous asphalt's average rate of 150 to 1,000 inches per hour, enhancing stormwater management efficiency.

Void content

Pervious concrete typically exhibits a higher void content of 15-25%, enhancing water permeability compared to porous asphalt's 15-20% void content, which balances permeability with structural flexibility.

Stormwater management

Pervious concrete offers superior stormwater infiltration and pollutant filtration compared to porous asphalt, enhancing stormwater management by reducing runoff volume and improving groundwater recharge.

Permeability coefficient

Pervious concrete typically has a permeability coefficient ranging from 1.0 x 10^-2 to 1.2 x 10^-1 cm/s, whereas porous asphalt usually exhibits permeability coefficients between 5.0 x 10^-2 and 1.5 x 10^-1 cm/s, making both materials highly effective for stormwater infiltration but with porous asphalt generally allowing slightly higher permeability.

Surface course materials

Pervious concrete offers higher water permeability and durability as a surface course material compared to porous asphalt, which provides greater flexibility and easier maintenance in stormwater management applications.

Hydrological performance

Pervious concrete offers higher infiltration rates and better stormwater management compared to porous asphalt, making it more effective in reducing surface runoff and enhancing groundwater recharge.

Subbase drainage layer

Porous asphalt offers superior subbase drainage performance compared to pervious concrete due to its higher permeability and enhanced water infiltration capabilities.

Structural load capacity

Pervious concrete typically exhibits higher structural load capacity than porous asphalt due to its denser aggregate matrix and higher compressive strength.

Clogging susceptibility

Previous concrete exhibits significantly lower clogging susceptibility than porous asphalt due to its larger pore structure and enhanced hydraulic conductivity.

Mix design optimization

Optimizing mix design for pervious concrete involves achieving a balance between hydraulic conductivity and structural strength by adjusting aggregate size and void content, whereas porous asphalt mix design optimization prioritizes maximizing air voids for permeability without compromising binder content and aggregate gradation.

pervious concrete vs porous asphalt Infographic

njnir.com

njnir.com