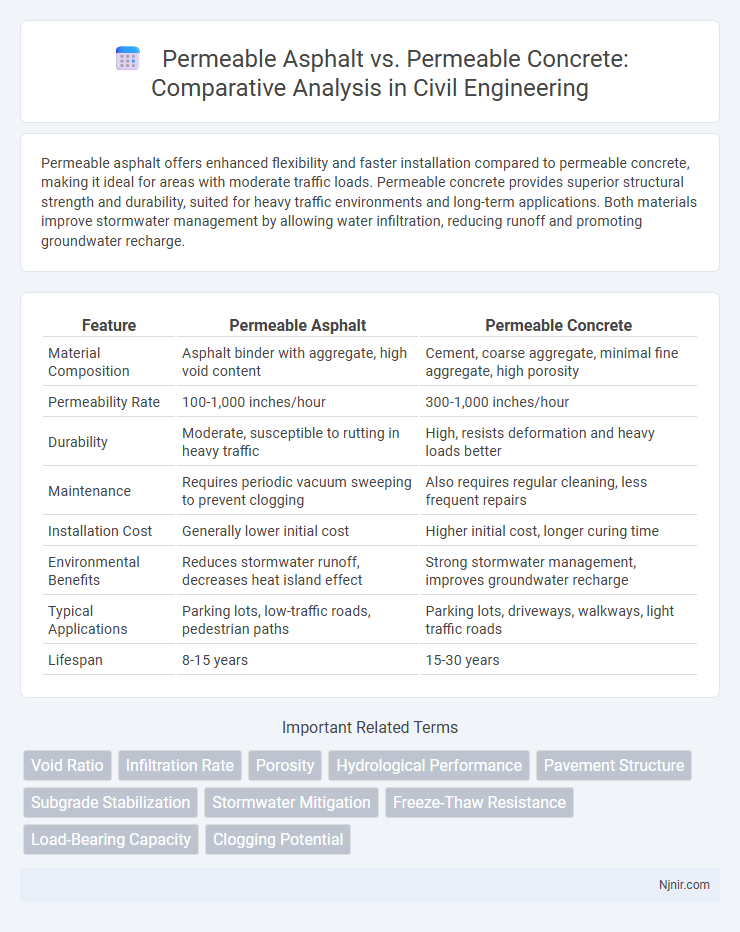

Permeable asphalt offers enhanced flexibility and faster installation compared to permeable concrete, making it ideal for areas with moderate traffic loads. Permeable concrete provides superior structural strength and durability, suited for heavy traffic environments and long-term applications. Both materials improve stormwater management by allowing water infiltration, reducing runoff and promoting groundwater recharge.

Table of Comparison

| Feature | Permeable Asphalt | Permeable Concrete |

|---|---|---|

| Material Composition | Asphalt binder with aggregate, high void content | Cement, coarse aggregate, minimal fine aggregate, high porosity |

| Permeability Rate | 100-1,000 inches/hour | 300-1,000 inches/hour |

| Durability | Moderate, susceptible to rutting in heavy traffic | High, resists deformation and heavy loads better |

| Maintenance | Requires periodic vacuum sweeping to prevent clogging | Also requires regular cleaning, less frequent repairs |

| Installation Cost | Generally lower initial cost | Higher initial cost, longer curing time |

| Environmental Benefits | Reduces stormwater runoff, decreases heat island effect | Strong stormwater management, improves groundwater recharge |

| Typical Applications | Parking lots, low-traffic roads, pedestrian paths | Parking lots, driveways, walkways, light traffic roads |

| Lifespan | 8-15 years | 15-30 years |

Introduction to Permeable Pavement Systems

Permeable pavement systems include permeable asphalt and permeable concrete, both designed to enhance stormwater management by allowing water to infiltrate through the surface. Permeable asphalt offers flexibility and rapid installation, making it suitable for parking lots and low-traffic roads, while permeable concrete provides higher durability and strength, ideal for heavier traffic areas. These systems reduce runoff, improve groundwater recharge, and help mitigate urban heat island effects.

Key Material Differences: Permeable Asphalt vs Permeable Concrete

Permeable asphalt consists of a mixture of asphalt binder and coarse aggregates designed to allow water infiltration, whereas permeable concrete uses cement, water, and coarse aggregates with minimal fine particles to maintain porosity. The binder in permeable asphalt is more flexible, providing better resistance to cracking, while permeable concrete offers higher compressive strength and durability under heavy loads. Material composition significantly influences installation techniques, lifecycle costs, and suitability for various environmental conditions and traffic demands.

Water Permeability and Drainage Performance

Permeable asphalt offers high water permeability due to its porous aggregate matrix, allowing rapid drainage and reducing surface runoff. Permeable concrete provides similarly effective drainage but often has a more uniform pore structure, enhancing water filtration and retention capabilities. Both materials improve stormwater management, yet permeable asphalt generally performs better in heavy rainfall scenarios due to faster water infiltration rates.

Structural Strength and Load-Bearing Capacity

Permeable asphalt offers moderate structural strength with flexibility suited for light to medium traffic, featuring high tensile strength but lower compressive resistance compared to permeable concrete. Permeable concrete provides superior load-bearing capacity and durability due to its rigid matrix, making it ideal for heavy traffic areas and industrial applications. Both materials support water infiltration, but permeable concrete withstands higher structural loads, enhancing longevity in demanding environments.

Installation Techniques and Construction Processes

Permeable asphalt requires specialized equipment for proper mixing and placement to ensure adequate void space for water infiltration, with installation typically completed in cooler temperatures to prevent binder migration. Permeable concrete involves a carefully controlled mix design with minimal fine aggregates and requires consistent vibration during placement to avoid clogging pores while enhancing strength. Both materials demand precise curing and compaction techniques to maintain structural integrity and permeability, with site preparation including grading and sub-base stabilization crucial to long-term performance.

Maintenance Requirements and Longevity

Permeable asphalt requires regular surface vacuuming and replenishing of voids to maintain infiltration rates, with typical lifespan around 10-15 years under normal traffic conditions. Permeable concrete demands less frequent maintenance, primarily periodic cleaning to prevent clogging, and offers greater durability with a lifespan of 20-30 years. Both materials need routine inspections to address sediment buildup, but permeable concrete generally provides longer-lasting performance and reduced maintenance costs over time.

Environmental Impact and Sustainability

Permeable asphalt and permeable concrete both enhance stormwater management by allowing water infiltration, reducing runoff, and mitigating urban flooding. Permeable concrete typically has a longer lifespan and higher strength, resulting in less frequent repairs and lower environmental impact over time. Permeable asphalt, while often more cost-effective initially, may require more maintenance but offers benefits in carbon emission reduction when produced with recycled materials.

Cost Analysis: Initial and Lifecycle Expenses

Permeable asphalt typically has a lower initial installation cost compared to permeable concrete, making it more budget-friendly for projects with tight upfront budgets. However, permeable concrete offers greater durability and requires less frequent maintenance, which can lead to lower lifecycle expenses over time. Careful cost analysis considering factors such as installation complexity, maintenance frequency, and expected lifespan is essential to determine the most cost-effective choice for sustainable pavement solutions.

Typical Applications and Suitability

Permeable asphalt is commonly used in parking lots, driveways, and low-traffic roadways due to its flexibility and quick installation, making it suitable for urban areas requiring efficient stormwater management. Permeable concrete excels in heavy-duty applications such as highways, industrial yards, and pedestrian walkways because of its superior compressive strength and durability. Both materials support groundwater recharge, but permeable concrete is preferred where load-bearing capacity and longevity are critical.

Case Studies and Field Performance Comparison

Case studies reveal that permeable asphalt typically exhibits higher initial permeability rates, allowing rapid stormwater infiltration in urban environments, while permeable concrete offers greater long-term durability under heavy traffic loads. Field performance comparisons indicate permeable asphalt requires more frequent maintenance due to clogging but performs better in colder climates with freeze-thaw cycles. In contrast, permeable concrete maintains structural integrity longer but may experience reduced permeability without regular cleaning, emphasizing the importance of site-specific evaluations for sustainable pavement solutions.

Void Ratio

Permeable asphalt typically has a void ratio of 15-20%, while permeable concrete offers a higher void ratio ranging from 20-30%, enhancing water infiltration and drainage efficiency.

Infiltration Rate

Permeable asphalt typically offers infiltration rates ranging from 100 to 500 inches per hour, whereas permeable concrete provides slightly lower rates between 50 and 200 inches per hour, making asphalt more effective for rapid stormwater management.

Porosity

Permeable asphalt typically exhibits higher porosity ranging from 15% to 20%, enabling superior water infiltration compared to permeable concrete, which generally has a lower porosity of 10% to 15%, affecting its drainage efficiency.

Hydrological Performance

Permeable asphalt offers faster infiltration rates and greater flexibility in water management compared to permeable concrete, which provides higher structural strength but slightly reduced permeability in hydrological performance.

Pavement Structure

Permeable asphalt features a flexible pavement structure with interconnected voids for water infiltration, while permeable concrete offers a rigid pavement structure with larger aggregate voids designed for increased durability and load-bearing capacity.

Subgrade Stabilization

Permeable asphalt provides superior subgrade stabilization due to its flexible structure and enhanced drainage capabilities compared to the rigid nature of permeable concrete.

Stormwater Mitigation

Permeable asphalt enhances stormwater mitigation by allowing faster infiltration and reducing runoff volume compared to permeable concrete, which offers greater durability but slower water absorption.

Freeze-Thaw Resistance

Permeable concrete exhibits superior freeze-thaw resistance compared to permeable asphalt due to its higher durability and lower susceptibility to cracking in cold climates.

Load-Bearing Capacity

Permeable concrete offers higher load-bearing capacity than permeable asphalt, making it more suitable for heavy traffic areas and industrial applications.

Clogging Potential

Permeable asphalt typically has a higher clogging potential than permeable concrete due to its smaller pore size and organic debris accumulation.

Permeable Asphalt vs Permeable Concrete Infographic

njnir.com

njnir.com