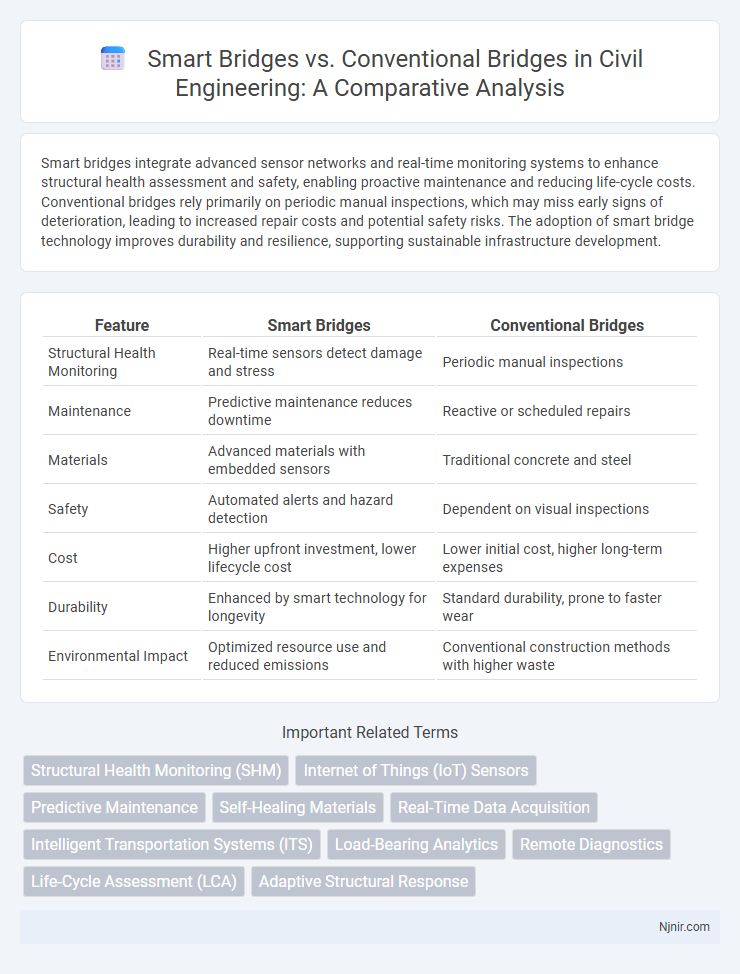

Smart bridges integrate advanced sensor networks and real-time monitoring systems to enhance structural health assessment and safety, enabling proactive maintenance and reducing life-cycle costs. Conventional bridges rely primarily on periodic manual inspections, which may miss early signs of deterioration, leading to increased repair costs and potential safety risks. The adoption of smart bridge technology improves durability and resilience, supporting sustainable infrastructure development.

Table of Comparison

| Feature | Smart Bridges | Conventional Bridges |

|---|---|---|

| Structural Health Monitoring | Real-time sensors detect damage and stress | Periodic manual inspections |

| Maintenance | Predictive maintenance reduces downtime | Reactive or scheduled repairs |

| Materials | Advanced materials with embedded sensors | Traditional concrete and steel |

| Safety | Automated alerts and hazard detection | Dependent on visual inspections |

| Cost | Higher upfront investment, lower lifecycle cost | Lower initial cost, higher long-term expenses |

| Durability | Enhanced by smart technology for longevity | Standard durability, prone to faster wear |

| Environmental Impact | Optimized resource use and reduced emissions | Conventional construction methods with higher waste |

Introduction to Smart Bridges and Conventional Bridges

Smart bridges integrate sensors, IoT devices, and AI technologies for real-time monitoring and proactive maintenance, enhancing safety and extending structural lifespan. Conventional bridges rely on periodic manual inspections and maintenance schedules, which may delay detection of structural issues and increase risks. These contrasting approaches highlight the shift towards digital infrastructure management in civil engineering.

Key Structural Differences

Smart bridges integrate advanced sensors and monitoring technologies within their structure, enabling real-time assessment of stress, strain, and environmental conditions, unlike conventional bridges which rely solely on periodic manual inspections. Materials used in smart bridges often include adaptive or self-healing composites that enhance durability and reduce maintenance, whereas conventional bridges predominantly use traditional steel and concrete without embedded intelligence. Structural designs in smart bridges emphasize modularity and responsiveness, allowing dynamic load adjustments, contrasting with the static, fixed configurations typical of conventional bridge construction.

Materials and Construction Techniques

Smart bridges utilize advanced materials such as fiber-reinforced polymers (FRPs) and self-healing concrete, enhancing durability and reducing maintenance costs compared to conventional bridges that primarily rely on steel and traditional concrete. Construction techniques for smart bridges incorporate sensor integration and modular prefabrication, enabling real-time structural health monitoring and faster assembly. In contrast, conventional bridges often employ labor-intensive, on-site casting and welding processes, which can prolong construction time and increase susceptibility to human error.

Sensor Integration and Real-Time Monitoring

Smart bridges utilize advanced sensor integration to continuously collect data on structural health, including strain, vibration, temperature, and displacement, enabling precise real-time monitoring and early detection of potential issues. Conventional bridges rely primarily on periodic manual inspections, which may miss subtle or emerging defects, leading to delayed maintenance and increased risk of structural failures. The implementation of Internet of Things (IoT) sensors and wireless communication in smart bridges enhances safety, reduces maintenance costs, and extends lifespan through proactive management.

Maintenance and Lifecycle Management

Smart bridges integrate advanced sensors and IoT technology to continuously monitor structural health, enabling predictive maintenance and reducing unexpected repair costs. Conventional bridges rely on scheduled inspections and manual assessments, often leading to delays in identifying critical issues and higher lifecycle expenses. Lifecycle management of smart bridges benefits from real-time data analytics, improving durability and safety while optimizing maintenance budgets over time.

Cost Analysis: Initial Investment vs Long-Term Savings

Smart bridges require a higher initial investment due to advanced sensor integration, automated monitoring systems, and IoT connectivity, which significantly increases upfront costs compared to conventional bridges. However, smart bridges offer substantial long-term savings by enabling real-time maintenance, reducing manual inspection labor, preventing major structural failures, and extending the bridge lifespan. Lifecycle cost analysis shows that reduced repair costs and improved safety features of smart bridges can offset the initial expenditure within 10 to 15 years, making them economically advantageous over traditional bridge designs.

Safety and Risk Mitigation

Smart bridges utilize integrated sensors and real-time monitoring systems to detect structural weaknesses, environmental changes, and traffic loads, significantly enhancing safety by enabling immediate response to potential hazards. Conventional bridges rely on scheduled inspections and manual assessments, which may delay the identification of risks and increase vulnerability to sudden failures. The advanced data analytics and predictive maintenance capabilities of smart bridges reduce the likelihood of catastrophic events and optimize risk mitigation strategies more effectively than traditional bridge designs.

Environmental Impact and Sustainability

Smart bridges utilize sensor technology and real-time data analytics to proactively monitor structural health, enabling timely maintenance that minimizes resource waste and environmental disruption compared to conventional bridges. They often incorporate sustainable materials like recycled composites and design elements that reduce the carbon footprint throughout the lifecycle of the structure. By optimizing longevity and reducing repair frequency, smart bridges contribute significantly to environmental sustainability and lower greenhouse gas emissions relative to traditional construction methods.

Case Studies: Successful Applications Worldwide

Smart bridges equipped with sensors and real-time monitoring systems have demonstrated enhanced safety and maintenance efficiency in case studies such as the Queensferry Crossing in Scotland and the Zolotoy Bridge in Russia. Data collected from structural health monitoring enables predictive maintenance, reducing downtime and extending the lifespan compared to conventional bridges. These smart infrastructure projects highlight the global shift toward integrating Internet of Things (IoT) technologies for improved resilience and cost-effective bridge management.

Future Trends in Bridge Technology

Smart bridges integrate advanced sensors, IoT connectivity, and real-time data analytics to monitor structural health, predict maintenance needs, and enhance safety, setting a new standard for infrastructure management. Future trends emphasize the use of artificial intelligence for autonomous damage detection, self-healing materials that extend lifespan, and energy harvesting technologies that power embedded systems. These innovations surpass conventional bridges by offering proactive maintenance, improved durability, and reduced operational costs, driving the evolution of resilient, intelligent transportation networks.

Structural Health Monitoring (SHM)

Smart bridges equipped with advanced Structural Health Monitoring (SHM) systems provide real-time data on stress, strain, and environmental conditions, enhancing safety and maintenance efficiency compared to conventional bridges lacking continuous monitoring capabilities.

Internet of Things (IoT) Sensors

Smart bridges equipped with Internet of Things (IoT) sensors enable real-time structural health monitoring, predictive maintenance, and enhanced safety compared to conventional bridges lacking such advanced sensor integration.

Predictive Maintenance

Smart bridges utilize advanced sensors and IoT technology to enable predictive maintenance by continuously monitoring structural health and detecting potential issues before they become critical, unlike conventional bridges that rely on scheduled inspections.

Self-Healing Materials

Smart bridges utilize self-healing materials that autonomously repair cracks and damage, significantly extending structural lifespan compared to conventional bridges made of traditional concrete and steel.

Real-Time Data Acquisition

Smart bridges utilize real-time data acquisition through embedded sensors and IoT technology to monitor structural health continuously, enabling proactive maintenance compared to conventional bridges that rely on periodic manual inspections.

Intelligent Transportation Systems (ITS)

Smart bridges integrated with Intelligent Transportation Systems (ITS) utilize real-time data analytics, sensors, and adaptive technologies to enhance safety, traffic management, and structural health monitoring, outperforming conventional bridges that rely on static designs and manual inspections.

Load-Bearing Analytics

Smart bridges leverage advanced load-bearing analytics using real-time sensor data and AI algorithms to enhance structural health monitoring and predictive maintenance, outperforming conventional bridges that rely on periodic manual inspections.

Remote Diagnostics

Smart bridges utilize remote diagnostics through embedded sensors and IoT technology to provide real-time monitoring and predictive maintenance, significantly enhancing safety and reducing inspection costs compared to conventional bridges.

Life-Cycle Assessment (LCA)

Smart bridges reduce environmental impact and maintenance costs compared to conventional bridges by integrating advanced sensors and materials that enable real-time monitoring and optimized life-cycle performance in Life-Cycle Assessment (LCA).

Adaptive Structural Response

Smart bridges utilize adaptive structural response technologies such as sensors and actuators to actively monitor and adjust to environmental loads, enhancing durability and safety compared to conventional bridges with static structural designs.

Smart Bridges vs Conventional Bridges Infographic

njnir.com

njnir.com