Box culverts offer greater load-bearing capacity and easier maintenance access compared to pipe culverts, making them ideal for larger water flow and roadway underpasses. Pipe culverts are more cost-effective and quicker to install, suitable for smaller drainage applications with limited space. Selecting between box and pipe culverts depends on site-specific factors such as hydraulic requirements, structural demands, and budget constraints.

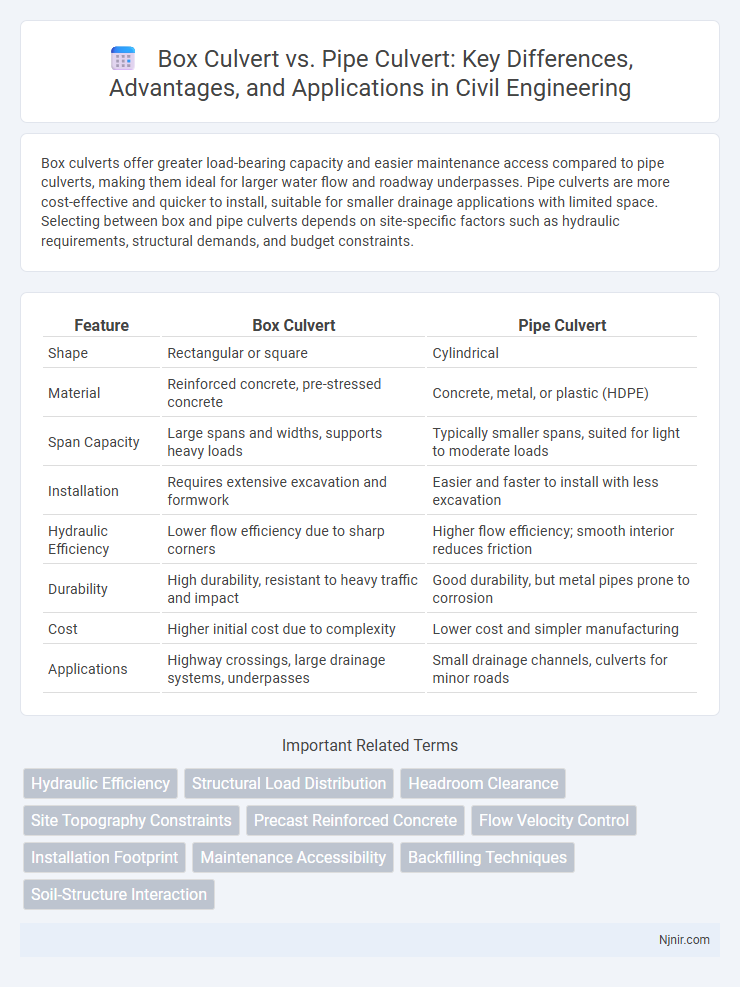

Table of Comparison

| Feature | Box Culvert | Pipe Culvert |

|---|---|---|

| Shape | Rectangular or square | Cylindrical |

| Material | Reinforced concrete, pre-stressed concrete | Concrete, metal, or plastic (HDPE) |

| Span Capacity | Large spans and widths, supports heavy loads | Typically smaller spans, suited for light to moderate loads |

| Installation | Requires extensive excavation and formwork | Easier and faster to install with less excavation |

| Hydraulic Efficiency | Lower flow efficiency due to sharp corners | Higher flow efficiency; smooth interior reduces friction |

| Durability | High durability, resistant to heavy traffic and impact | Good durability, but metal pipes prone to corrosion |

| Cost | Higher initial cost due to complexity | Lower cost and simpler manufacturing |

| Applications | Highway crossings, large drainage systems, underpasses | Small drainage channels, culverts for minor roads |

Introduction to Box Culvert and Pipe Culvert

Box culverts, typically constructed from reinforced concrete, are rectangular or square structures used to channel water under roads or railways, offering high strength and durability for larger flow capacities. Pipe culverts, generally made from materials like steel, concrete, or plastic, feature a circular cross-section suited for smaller flows and easier installation in confined spaces. The choice between box and pipe culverts depends on factors such as hydraulic capacity, site conditions, and structural requirements.

Structural Design Differences

Box culverts feature a rectangular cross-section providing greater structural stability under heavy loads and better resistance to soil pressure compared to pipe culverts, which have a circular shape optimized for efficient water flow and pressure distribution. The flat slab design of box culverts allows integration with roadways and embankments, while pipe culverts rely on arch action for load transfer and require less excavation and embedment depth. Material choices and reinforcement detailing also differ, with box culverts often constructed from reinforced concrete, accommodating higher shear and bending moments, whereas pipe culverts use reinforced or corrugated steel designed for uniform external loading conditions.

Material Requirements and Durability

Box culverts require reinforced concrete for structural stability and are preferred in situations demanding higher load capacity and wider spans. Pipe culverts, typically made from corrugated metal or concrete pipes, offer easier installation but may require additional protective coatings to resist corrosion. Durability in box culverts stems from their solid, rigid construction, while pipe culverts depend on material quality and maintenance to prevent deterioration under varying environmental conditions.

Installation Methods and Construction Time

Box culverts typically require extensive excavation and formwork, leading to longer installation times compared to pipe culverts. Pipe culverts, available in pre-manufactured sections, facilitate quicker assembly and reduced onsite labor, accelerating overall construction time. Installation of box culverts involves curing periods for concrete, whereas pipe culverts often allow immediate backfilling and load application.

Hydraulic Performance and Flow Capacity

Box culverts generally offer superior hydraulic performance and flow capacity compared to pipe culverts due to their larger cross-sectional area and rectangular shape, which reduces flow resistance and allows for higher discharge rates. The flat bottom of box culverts facilitates smoother flow transitions and sediment passage, minimizing clogging and energy loss. Pipe culverts, typically circular, have limited flow capacity and are more prone to turbulence and sediment accumulation, impacting long-term hydraulic efficiency.

Suitability for Site Conditions

Box culverts offer superior adaptability for sites with wide spans and shallow cover due to their rectangular shape and high load-bearing capacity, making them ideal for highways and urban drainage systems. Pipe culverts suit locations with limited space and deeper cover requirements, as their circular cross-section efficiently handles high-pressure loads and allows for easier installation in narrow trenches. Selection depends on factors such as soil type, hydraulic requirements, load conditions, and available construction space.

Maintenance and Inspection Needs

Box culverts require less frequent maintenance and easier inspection thanks to their larger internal space allowing better accessibility for cleaning and structural assessments. Pipe culverts often demand more frequent inspection due to potential clogging and limited access, which complicates debris removal and condition monitoring. The durability of box culverts generally reduces long-term repair costs compared to pipe culverts, which may face corrosion or joint failures more rapidly.

Cost Comparison and Budget Considerations

Box culverts generally have higher initial construction costs compared to pipe culverts due to their larger size and material requirements, especially when using reinforced concrete. Pipe culverts are often more budget-friendly for smaller spans and lower load conditions, benefiting from prefabricated steel or corrugated metal options that reduce installation time and labor expenses. Long-term maintenance costs for box culverts may be lower because of their durability and resistance to corrosion, impacting overall lifecycle budget considerations.

Common Applications in Civil Engineering

Box culverts are commonly used for highway underpasses, pedestrian crossings, and drainage channels due to their ability to handle large spans and heavy loads with ease. Pipe culverts are preferred in stormwater management, small road crossings, and irrigation systems because of their ease of installation and cost-effectiveness for smaller flow capacities. Both are integral components in civil engineering projects for efficient water conveyance and infrastructure support.

Advantages and Disadvantages of Each Type

Box culverts offer superior load-bearing capacity and are ideal for wide-span drainage or pedestrian underpasses, providing easy maintenance and durability against heavy traffic. Pipe culverts are cost-effective, quick to install, and suitable for smaller, narrow water flow areas but may face clogging issues and limited load capacity. While box culverts require higher initial investment and more space, pipe culverts are less flexible in size customization and less resistant to environmental damage over time.

Hydraulic Efficiency

Box culverts generally offer higher hydraulic efficiency than pipe culverts due to their larger cross-sectional area and smoother flow transitions, reducing head loss and improving water conveyance capacity.

Structural Load Distribution

Box culverts evenly distribute structural loads due to their rectangular shape and rigid reinforced concrete construction, while pipe culverts primarily transfer loads through their circular arch action, making box culverts more suitable for heavy load applications.

Headroom Clearance

Box culverts generally provide greater headroom clearance than pipe culverts, making them more suitable for situations requiring larger vertical space for traffic or water flow.

Site Topography Constraints

Box culverts are preferred over pipe culverts in sites with variable topography due to their ability to handle larger loads and accommodate irregular ground slopes more effectively.

Precast Reinforced Concrete

Precast reinforced concrete box culverts provide superior durability, larger load-bearing capacity, and easier installation compared to pipe culverts, making them ideal for heavy traffic and large span applications.

Flow Velocity Control

Box culverts provide better flow velocity control than pipe culverts due to their larger cross-sectional area and shape, reducing hydraulic energy and minimizing erosion risks.

Installation Footprint

Box culverts require a larger installation footprint than pipe culverts due to their rectangular cross-section and need for extensive excavation and subgrade preparation.

Maintenance Accessibility

Box culverts offer easier maintenance accessibility due to their larger internal space compared to pipe culverts, which often have restricted access for inspection and cleaning.

Backfilling Techniques

Backfilling techniques for box culverts typically involve layered compaction with granular material to ensure structural stability, while pipe culverts require careful bedding and zone backfilling to prevent deformation and promote load distribution.

Soil-Structure Interaction

Soil-structure interaction in box culverts provides greater load distribution and stability compared to pipe culverts due to their rigid rectangular shape and larger contact area with the surrounding soil.

Box Culvert vs Pipe Culvert Infographic

njnir.com

njnir.com