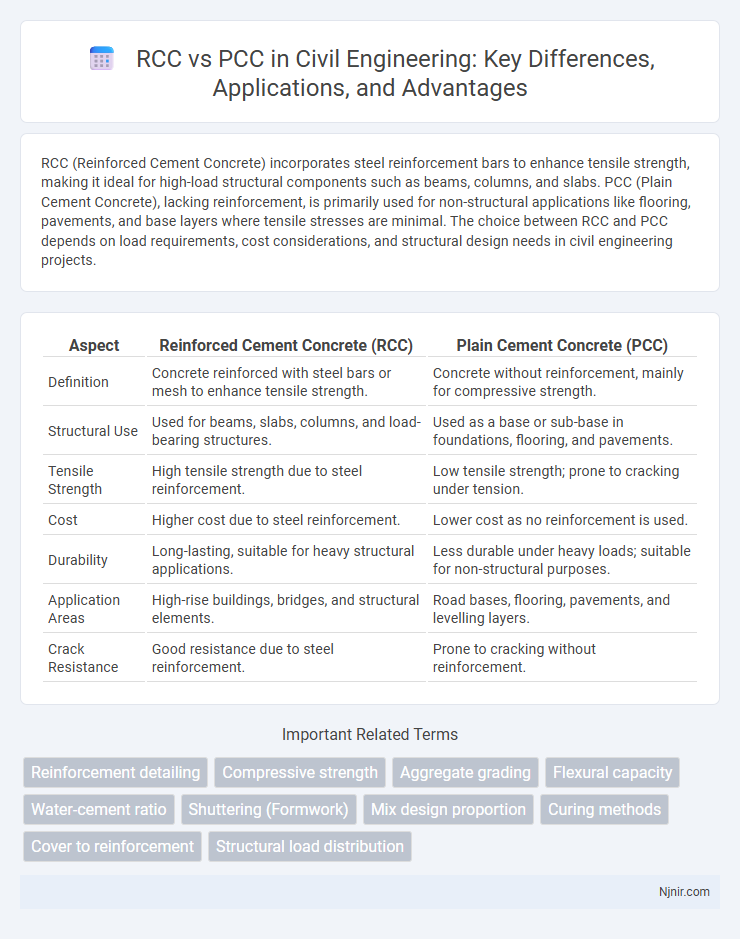

RCC (Reinforced Cement Concrete) incorporates steel reinforcement bars to enhance tensile strength, making it ideal for high-load structural components such as beams, columns, and slabs. PCC (Plain Cement Concrete), lacking reinforcement, is primarily used for non-structural applications like flooring, pavements, and base layers where tensile stresses are minimal. The choice between RCC and PCC depends on load requirements, cost considerations, and structural design needs in civil engineering projects.

Table of Comparison

| Aspect | Reinforced Cement Concrete (RCC) | Plain Cement Concrete (PCC) |

|---|---|---|

| Definition | Concrete reinforced with steel bars or mesh to enhance tensile strength. | Concrete without reinforcement, mainly for compressive strength. |

| Structural Use | Used for beams, slabs, columns, and load-bearing structures. | Used as a base or sub-base in foundations, flooring, and pavements. |

| Tensile Strength | High tensile strength due to steel reinforcement. | Low tensile strength; prone to cracking under tension. |

| Cost | Higher cost due to steel reinforcement. | Lower cost as no reinforcement is used. |

| Durability | Long-lasting, suitable for heavy structural applications. | Less durable under heavy loads; suitable for non-structural purposes. |

| Application Areas | High-rise buildings, bridges, and structural elements. | Road bases, flooring, pavements, and levelling layers. |

| Crack Resistance | Good resistance due to steel reinforcement. | Prone to cracking without reinforcement. |

Introduction to RCC and PCC

Reinforced Cement Concrete (RCC) combines concrete's compressive strength with steel reinforcement's tensile strength, making it ideal for structural elements in buildings and infrastructure. Plain Cement Concrete (PCC), also known as unreinforced concrete, lacks steel reinforcement, providing good compressive strength but limited tensile capacity. RCC is extensively used in beams, columns, slabs, and foundations where tensile stresses are significant, while PCC is typically used for non-structural applications like flooring and pavements.

Composition and Materials

RCC (Reinforced Cement Concrete) combines cement, fine aggregates, coarse aggregates, water, and steel reinforcement bars to enhance tensile strength and overall structural durability. PCC (Plain Cement Concrete) consists of cement, fine aggregates, coarse aggregates, and water without any steel reinforcement, making it suitable for non-load-bearing applications. The presence of steel reinforcement in RCC significantly improves its resistance to tensile stresses compared to PCC, which primarily withstands compressive forces.

Structural Properties Comparison

Reinforced Cement Concrete (RCC) exhibits significantly higher tensile strength compared to Plain Cement Concrete (PCC) due to the embedded steel reinforcement, which effectively resists bending and tension forces. PCC primarily offers high compressive strength but lacks flexibility and ductility, making it suitable for non-structural applications such as flooring or pavement. The superior load-bearing capacity and crack resistance of RCC make it the preferred choice for structural elements like beams, columns, and slabs in construction.

Typical Applications in Construction

Reinforced Cement Concrete (RCC) is widely used in structural elements like beams, columns, slabs, and foundations due to its high tensile strength and durability, making it ideal for load-bearing applications in buildings and bridges. Plain Cement Concrete (PCC), on the other hand, is commonly applied as a base or bedding layer beneath foundations, pavements, and flooring where tensile strength requirements are minimal. RCC is preferred in high-stress zones, while PCC serves as a cost-effective, non-structural layer providing a stable and level surface for subsequent construction activities.

Advantages of RCC over PCC

Reinforced Cement Concrete (RCC) offers superior tensile strength compared to Plain Cement Concrete (PCC) due to the embedded steel reinforcement, making it ideal for load-bearing structures. RCC provides enhanced durability and crack resistance, improving the longevity of buildings, bridges, and other infrastructures. The flexibility of RCC allows for more complex architectural designs and efficient material usage, resulting in cost-effective construction solutions.

Advantages of PCC over RCC

Plain Cement Concrete (PCC) offers several advantages over Reinforced Cement Concrete (RCC) including lower construction costs due to the absence of steel reinforcement and simpler mixing and placing processes. PCC provides excellent compressive strength, making it ideal for flooring, foundation beds, and pavements where tensile strength is less critical. Its reduced maintenance requirements and resistance to corrosion enhance durability in non-structural applications compared to RCC.

Cost Analysis: RCC vs PCC

Reinforced Cement Concrete (RCC) typically incurs higher initial costs due to steel reinforcement and complex labor requirements compared to Plain Cement Concrete (PCC), which is simpler and cheaper to produce. RCC offers superior durability and load-bearing capacity, reducing long-term maintenance expenses, whereas PCC involves lower upfront investment but may require more frequent repairs over time. Evaluating the total cost of ownership, RCC often proves more economical for structural applications despite higher initial expenditure.

Durability and Maintenance Requirements

Reinforced Cement Concrete (RCC) offers superior durability due to its embedded steel reinforcement, which enhances tensile strength and resistance against cracking and structural failure. Plain Cement Concrete (PCC), lacking reinforcement, is more prone to surface deterioration and less effective in handling tensile stress, leading to potential maintenance challenges over time. RCC typically requires less frequent maintenance, whereas PCC may need more regular repairs to address wear and environmental damage.

Environmental Impacts

RCC (Roller Compacted Concrete) significantly reduces environmental impacts compared to PCC (Portland Cement Concrete) by lowering cement content and incorporating industrial by-products like fly ash, which decreases CO2 emissions during production. The rapid construction time of RCC minimizes site disturbances and energy consumption, contributing to a smaller carbon footprint. RCC's durability and reduced need for maintenance also limit resource use and waste generation throughout its lifecycle.

Choosing Between RCC and PCC

Choosing between RCC (Reinforced Cement Concrete) and PCC (Plain Cement Concrete) depends on structural requirements and load-bearing capacity. RCC is ideal for frameworks needing high tensile strength and durability due to its steel reinforcement, making it suitable for beams, columns, and slabs. PCC, lacking reinforcement, is best for non-structural applications like flooring, pavements, and base layers where compressive strength alone suffices.

Reinforcement detailing

Reinforcement detailing in RCC involves tightly spaced steel bars with stirrups for structural strength, whereas PCC typically lacks reinforcement, relying on plain concrete without steel bars.

Compressive strength

RCC (Reinforced Cement Concrete) typically exhibits higher compressive strength than PCC (Plain Cement Concrete) due to the inclusion of steel reinforcement that enhances load-bearing capacity and crack resistance.

Aggregate grading

RCC uses coarse and fine aggregates with specific grading zones to achieve high strength and durability, while PCC employs a more uniform aggregate grading for general construction and reduced cost.

Flexural capacity

RCC (Reinforced Cement Concrete) offers higher flexural capacity than PCC (Plain Cement Concrete) due to the inclusion of steel reinforcement that improves tensile strength.

Water-cement ratio

RCC typically uses a lower water-cement ratio than PCC to enhance strength and durability.

Shuttering (Formwork)

RCC requires sturdy, reusable shuttering made of steel or aluminum to withstand high concrete pressure and ensure precise shaping, while PCC often uses simpler, less durable formwork due to lower structural demands.

Mix design proportion

RCC mix design typically uses a cement:sand:aggregate ratio of 1:1.5:3 with reduced water-cement ratio, while PCC mix design generally follows a simpler 1:2:4 ratio emphasizing higher cement content for enhanced workability and surface finish.

Curing methods

RCC (Roller Compacted Concrete) curing typically involves minimal water curing due to its dry mix and rapid compaction, whereas PCC (Plain Cement Concrete) requires thorough water curing methods such as ponding, sprinkling, or covering with wet burlap to ensure proper hydration and strength development.

Cover to reinforcement

RCC requires a minimum cover of 25 mm to reinforcement for durability, whereas PCC typically uses a smaller cover of around 10-15 mm due to lower reinforcement requirements.

Structural load distribution

RCC (Reinforced Cement Concrete) distributes structural loads through embedded steel reinforcement that bears tensile stresses, while PCC (Plain Cement Concrete) primarily handles compressive loads without tensile reinforcement, limiting its load distribution capacity.

RCC vs PCC Infographic

njnir.com

njnir.com