Cold recycling uses reclaimed asphalt pavement mixed with emulsifiers at ambient temperatures, offering energy savings and environmental benefits compared to Hot Mix Asphalt, which requires heating aggregates and binder to high temperatures for mixing and compaction. Cold recycling enhances pavement rehabilitation by recycling existing materials on-site, reducing transportation costs and carbon emissions, whereas Hot Mix Asphalt provides superior durability and strength for high-traffic roads. Selecting between these methods depends on project specifications, budget constraints, and desired pavement performance.

Table of Comparison

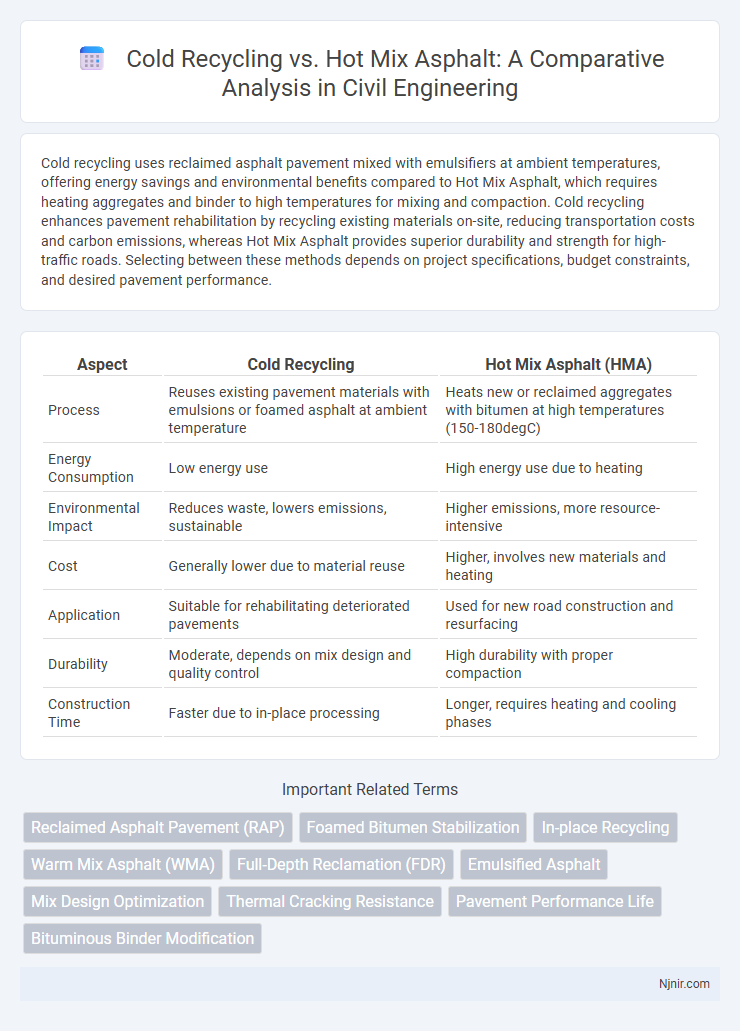

| Aspect | Cold Recycling | Hot Mix Asphalt (HMA) |

|---|---|---|

| Process | Reuses existing pavement materials with emulsions or foamed asphalt at ambient temperature | Heats new or reclaimed aggregates with bitumen at high temperatures (150-180degC) |

| Energy Consumption | Low energy use | High energy use due to heating |

| Environmental Impact | Reduces waste, lowers emissions, sustainable | Higher emissions, more resource-intensive |

| Cost | Generally lower due to material reuse | Higher, involves new materials and heating |

| Application | Suitable for rehabilitating deteriorated pavements | Used for new road construction and resurfacing |

| Durability | Moderate, depends on mix design and quality control | High durability with proper compaction |

| Construction Time | Faster due to in-place processing | Longer, requires heating and cooling phases |

Introduction to Cold Recycling and Hot Mix Asphalt

Cold recycling involves reusing existing asphalt pavement by milling, mixing it with stabilizing agents, and placing it back on the road without heating, making it an eco-friendly and cost-effective rehabilitation method. Hot Mix Asphalt (HMA) consists of a mixture of heated aggregates and asphalt binder, produced at temperatures typically between 275degF and 325degF, offering durable and flexible pavement solutions for new constructions and overlays. Both methods are integral to modern road maintenance strategies, with cold recycling emphasizing sustainability and HMA ensuring high-performance surface quality.

Principles and Processes of Cold Recycling

Cold recycling involves the in-place reuse of existing pavement materials, minimizing the need for new aggregates and reducing environmental impact. The process begins with milling or scarifying the old asphalt layer, followed by the addition of binding agents like emulsified asphalt or foamed bitumen to stabilize the recycled mixture. This technique contrasts with Hot Mix Asphalt (HMA), which requires heating aggregates and asphalt binder to high temperatures before mixing and laying, resulting in higher energy consumption and emissions.

Overview of Hot Mix Asphalt Technology

Hot Mix Asphalt (HMA) technology involves heating aggregates and asphalt binder to high temperatures to create a homogeneous mix, facilitating easy placement and compaction for durable pavement surfaces. The precise temperature control, typically between 275degF and 325degF, ensures optimal binder viscosity, leading to enhanced adhesive properties and improved resistance to rutting and cracking. This method allows for rapid road construction and rehabilitation, producing pavements with superior structural integrity and long service life compared to Cold Recycling techniques.

Materials Used in Cold Recycling vs Hot Mix Asphalt

Cold recycling utilizes reclaimed asphalt pavement (RAP) mixed with emulsified or foamed bitumen, along with additives such as cement or lime to enhance stability and moisture resistance. Hot Mix Asphalt incorporates virgin aggregates combined with heated asphalt binder at temperatures ranging from 275degF to 325degF, ensuring strong adhesion and durability. The choice of materials in cold recycling promotes sustainability by reusing existing pavement, while Hot Mix Asphalt emphasizes performance through fresh, high-quality components.

Environmental Impact Comparison

Cold recycling significantly reduces greenhouse gas emissions by reusing existing asphalt materials on-site, cutting down on the need for new raw materials and transportation energy. Hot mix asphalt production consumes more energy due to heating virgin aggregates and asphalt binder, leading to higher carbon dioxide emissions and increased fuel consumption. Evaluations show that cold recycling lowers environmental footprint by minimizing landfill waste and resource extraction, aligning with sustainable road construction practices.

Cost Analysis: Cold Recycling versus Hot Mix Asphalt

Cold recycling reduces project costs by utilizing on-site materials, significantly lowering transportation and material expenses compared to hot mix asphalt production. Hot mix asphalt involves higher energy consumption and asphalt binder costs, increasing overall expenditure, especially in large-scale projects. Cold recycling offers a more sustainable and cost-effective solution by minimizing raw material needs and labor intensity without compromising pavement durability.

Performance and Durability Considerations

Cold recycling utilizes in-place materials with lower curing temperatures, offering enhanced environmental benefits and rapid construction but may exhibit reduced initial strength compared to hot mix asphalt. Hot mix asphalt provides superior compaction and density, resulting in greater resistance to rutting and cracking, which improves long-term durability under heavy traffic loads. Performance differences depend on project requirements, climate conditions, and maintenance practices, making material selection critical for optimizing pavement lifespan.

Construction Speed and Traffic Disruption

Cold recycling accelerates construction speed by allowing pavement rehabilitation without complete removal of existing layers, minimizing the need for extensive curing times compared to Hot Mix Asphalt (HMA). Hot Mix Asphalt requires heating and cooling phases, leading to longer project durations and more significant traffic disruptions due to lane closures and extended work zones. Cold recycling is preferred in high-traffic areas for its ability to reduce downtime and maintain smoother traffic flow during road repairs.

Applications and Suitable Use Cases

Cold recycling is ideal for rehabilitating damaged pavements without the need for high temperatures, making it suitable for moderate-traffic roads and environmentally sensitive areas where energy consumption and emissions must be minimized. Hot mix asphalt (HMA) provides superior durability and smoothness, preferred for high-traffic highways, airports, and urban streets requiring rapid load-bearing strength and long-lasting surface quality. Selecting between cold recycling and HMA depends on project scale, climatic conditions, budget constraints, and the desired lifespan of the pavement.

Future Trends in Pavement Rehabilitation Methods

Future trends in pavement rehabilitation increasingly favor sustainable solutions like cold recycling due to its reduced energy consumption and lower greenhouse gas emissions compared to hot mix asphalt. Advances in cold recycling technology focus on improved binder formulations and enhanced in-place recycling processes, enabling longer-lasting pavements with minimized environmental impact. Integration of smart materials and real-time monitoring sensors is expected to optimize both cold recycling and hot mix asphalt applications, enhancing durability and maintenance efficiency.

Reclaimed Asphalt Pavement (RAP)

Reclaimed Asphalt Pavement (RAP) in Cold Recycling preserves up to 100% of existing materials by processing in-place without heating, while Hot Mix Asphalt integrates typically 10-30% RAP by reheating and blending with new asphalt binder to optimize pavement performance and sustainability.

Foamed Bitumen Stabilization

Foamed bitumen stabilization in cold recycling provides energy-efficient, sustainable pavement rehabilitation by enabling lower temperature mixing, reduced emissions, and improved moisture resistance compared to traditional hot mix asphalt.

In-place Recycling

In-place cold recycling uses lower temperatures to reclaim and reuse existing pavement materials directly on site, reducing energy consumption and environmental impact compared to traditional hot mix asphalt methods that require heating and transporting new materials.

Warm Mix Asphalt (WMA)

Warm Mix Asphalt (WMA) offers significant environmental benefits and energy savings compared to Cold Recycling and Hot Mix Asphalt by enabling lower production temperatures and improved workability.

Full-Depth Reclamation (FDR)

Full-Depth Reclamation (FDR) utilizing Cold Recycling economically restores pavement by recycling existing materials on-site, whereas Hot Mix Asphalt involves layering new heated asphalt, offering faster curing but higher costs and energy use.

Emulsified Asphalt

Emulsified asphalt in cold recycling significantly reduces energy consumption and emissions compared to hot mix asphalt by enabling reclaiming and repurposing of existing pavement materials without the need for high-temperature heating.

Mix Design Optimization

Cold recycling optimizes mix design by incorporating recycled asphalt pavement with minimal heating, reducing energy use and emissions while maintaining structural integrity, whereas hot mix asphalt relies on high-temperature processing to achieve optimal binder-aggregate adhesion and durability.

Thermal Cracking Resistance

Cold recycling enhances thermal cracking resistance by retaining aged binder properties, whereas hot mix asphalt offers superior initial flexibility but may be more prone to thermal cracking under extreme temperature variations.

Pavement Performance Life

Cold recycling extends pavement performance life by enhancing structural integrity with lower energy consumption, while hot mix asphalt offers superior immediate durability but involves higher thermal stresses reducing long-term lifespan.

Bituminous Binder Modification

Cold recycling uses reclaimed asphalt with bituminous binder modified by emulsifiers or foaming techniques, while hot mix asphalt relies on heat-modified bitumen with additives like polymers for enhanced performance.

Cold Recycling vs Hot Mix Asphalt Infographic

njnir.com

njnir.com