3D printing in civil engineering offers unprecedented design flexibility and rapid on-site construction by directly fabricating complex components layer by layer, reducing material waste. Prefabrication involves manufacturing structural elements off-site under controlled conditions, ensuring higher quality and faster assembly times on-site compared to traditional methods. While 3D printing excels in customization and reducing labor intensity, prefabrication remains advantageous for large-scale projects requiring standardized, repeatable components.

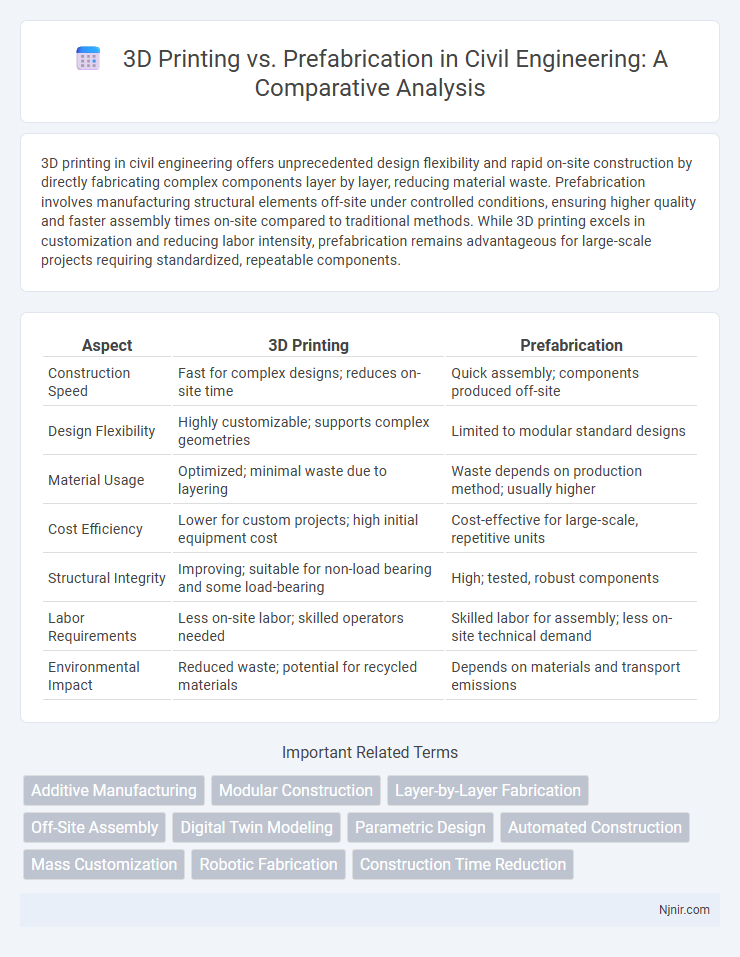

Table of Comparison

| Aspect | 3D Printing | Prefabrication |

|---|---|---|

| Construction Speed | Fast for complex designs; reduces on-site time | Quick assembly; components produced off-site |

| Design Flexibility | Highly customizable; supports complex geometries | Limited to modular standard designs |

| Material Usage | Optimized; minimal waste due to layering | Waste depends on production method; usually higher |

| Cost Efficiency | Lower for custom projects; high initial equipment cost | Cost-effective for large-scale, repetitive units |

| Structural Integrity | Improving; suitable for non-load bearing and some load-bearing | High; tested, robust components |

| Labor Requirements | Less on-site labor; skilled operators needed | Skilled labor for assembly; less on-site technical demand |

| Environmental Impact | Reduced waste; potential for recycled materials | Depends on materials and transport emissions |

Introduction to 3D Printing and Prefabrication in Civil Engineering

3D printing in civil engineering involves the layer-by-layer additive manufacturing of building components, enabling complex geometries and rapid prototyping with materials like concrete and polymers. Prefabrication refers to the off-site production of standardized building elements, improving construction speed, quality control, and reducing on-site labor. Both technologies revolutionize construction by enhancing efficiency, sustainability, and design flexibility.

Historical Evolution of Construction Methods

3D printing in construction evolved from rapid prototyping technologies in the 1980s, advancing significantly in the 2010s with large-scale concrete printers enabling complex, customizable structures. Prefabrication has roots in early 20th-century industrialization, accelerating post-World War II through mass-produced components that reduced on-site labor and construction time. The historical shift showcases a trend from manual, labor-intensive methods to automated, precise manufacturing processes enhancing efficiency and sustainability.

Core Technologies Behind 3D Printing and Prefabrication

3D printing utilizes additive manufacturing technology, where successive layers of material such as thermoplastics, resins, or metal powders are precisely deposited to create complex structures directly from digital 3D models. Prefabrication relies on modular construction techniques, leveraging factory-controlled production of standardized components like panels, beams, and modules, which are later assembled on-site for efficiency and quality control. Key technologies driving 3D printing include CAD software, slicing algorithms, and advanced extrusion or sintering systems, while prefabrication depends heavily on CNC machining, robotics, and automated material handling for consistent and repeatable production.

Speed and Efficiency in Project Delivery

3D printing accelerates project delivery by enabling rapid production of complex components directly from digital models, reducing manual labor and minimizing material waste. Prefabrication streamlines construction by assembling standardized modules offsite under controlled conditions, enhancing quality control and allowing simultaneous site preparation. Both methods significantly improve efficiency, with 3D printing excelling in customization speed and prefabrication optimizing large-scale volume production.

Material Usage and Sustainability Considerations

3D printing in construction enables precise material usage by depositing only the necessary amount of concrete or composites, significantly reducing waste compared to traditional prefabrication methods that often generate excess offcuts and packaging waste. Prefabrication benefits from controlled factory environments that optimize material efficiency and allow recycling of scrap materials, enhancing sustainability through reduced on-site waste and lower carbon emissions from transportation. Both methods contribute to sustainable construction, with 3D printing offering greater customization and material optimization, while prefabrication ensures consistent quality and economies of scale for efficient resource management.

Cost-Benefit Analysis: 3D Printing vs Prefabrication

3D printing offers cost benefits through reduced material waste and faster prototyping, making it ideal for complex, customized components that require minimal labor. Prefabrication provides economies of scale by producing standardized building elements off-site, resulting in lower labor costs and shorter construction timelines for repetitive projects. A comprehensive cost-benefit analysis reveals that 3D printing excels in flexibility and innovation, while prefabrication is more cost-effective for large-scale, uniform production.

Design Flexibility and Customization Potential

3D printing offers unparalleled design flexibility by enabling complex geometries and intricate details that traditional prefabrication methods cannot easily achieve. Prefabrication excels in standardized, large-scale production with consistent quality but often limits customization due to modular constraints. The customization potential of 3D printing supports rapid prototyping and bespoke designs tailored to specific requirements, making it ideal for unique architectural elements and personalized construction components.

Structural Performance and Quality Control

3D printing offers precise control over complex geometries and material distribution, resulting in enhanced structural performance through optimized load-bearing capabilities and reduced material waste. Prefabrication ensures consistent quality control by manufacturing components in controlled factory environments, minimizing on-site errors and variability in material properties. Both methods improve construction efficiency, but 3D printing excels in customizability while prefabrication provides proven reliability and standardized performance.

Challenges and Limitations in Implementation

3D printing faces challenges in scalability and material constraints, limiting its application in large-scale construction projects compared to prefabrication methods. Prefabrication struggles with transportation logistics and site customization, often resulting in increased costs and design restrictions. Both techniques encounter integration issues with existing building codes and require skilled labor for successful implementation.

Future Trends and Innovations in Construction

3D printing and prefabrication are revolutionizing construction by enabling faster project completion and reducing material waste through advanced automation. Emerging trends include integrating artificial intelligence with 3D printing to optimize design precision and employing modular prefabricated components enhanced with smart sensors for real-time structural health monitoring. Innovations such as bio-based printable materials and adaptive prefabricated units aim to improve sustainability and resilience in future building projects.

Additive Manufacturing

Additive manufacturing in 3D printing enables precise, cost-effective construction of complex components layer by layer, offering greater design flexibility and reduced material waste compared to traditional prefabrication methods.

Modular Construction

Modular construction leverages both 3D printing for custom, intricate components and prefabrication for standardized, high-volume modules, optimizing efficiency and reducing construction time.

Layer-by-Layer Fabrication

3D printing utilizes precise layer-by-layer fabrication to create complex structures with minimal waste, whereas prefabrication assembles pre-made components but lacks the same level of customization and material efficiency.

Off-Site Assembly

3D printing enables precise, customizable off-site assembly by fabricating complex components layer-by-layer, whereas prefabrication involves assembling pre-made parts off-site for faster construction and reduced on-site labor.

Digital Twin Modeling

Digital twin modeling enhances 3D printing and prefabrication efficiency by providing real-time, data-driven simulations that optimize design accuracy and construction processes.

Parametric Design

Parametric design enhances both 3D printing and prefabrication by enabling precise customization and optimization of complex geometries for efficient construction workflows.

Automated Construction

Automated construction leverages 3D printing for complex, customizable components and prefabrication for efficient, large-scale assembly, optimizing speed and precision in building projects.

Mass Customization

3D printing enables mass customization by allowing precise, on-demand production of complex, personalized components, whereas prefabrication relies on standardized modules with limited customization options and longer lead times.

Robotic Fabrication

Robotic fabrication enhances both 3D printing and prefabrication by increasing precision, reducing material waste, and accelerating construction timelines in modern building processes.

Construction Time Reduction

3D printing reduces construction time by accelerating on-site assembly and minimizing labor, whereas prefabrication shortens timelines through off-site manufacturing and rapid on-site installation.

3D Printing vs Prefabrication Infographic

njnir.com

njnir.com