Steel fibre concrete enhances durability and crack resistance by distributing tensile stresses more evenly than traditional rebar, reducing the risk of structural failure. The integration of steel fibres simplifies construction processes, eliminating the need for intricate rebar placement and minimising labour costs. Its superior impact resistance and improved flexural strength make steel fibre concrete an optimal choice for industrial floors and pavements compared to conventional reinforced concrete.

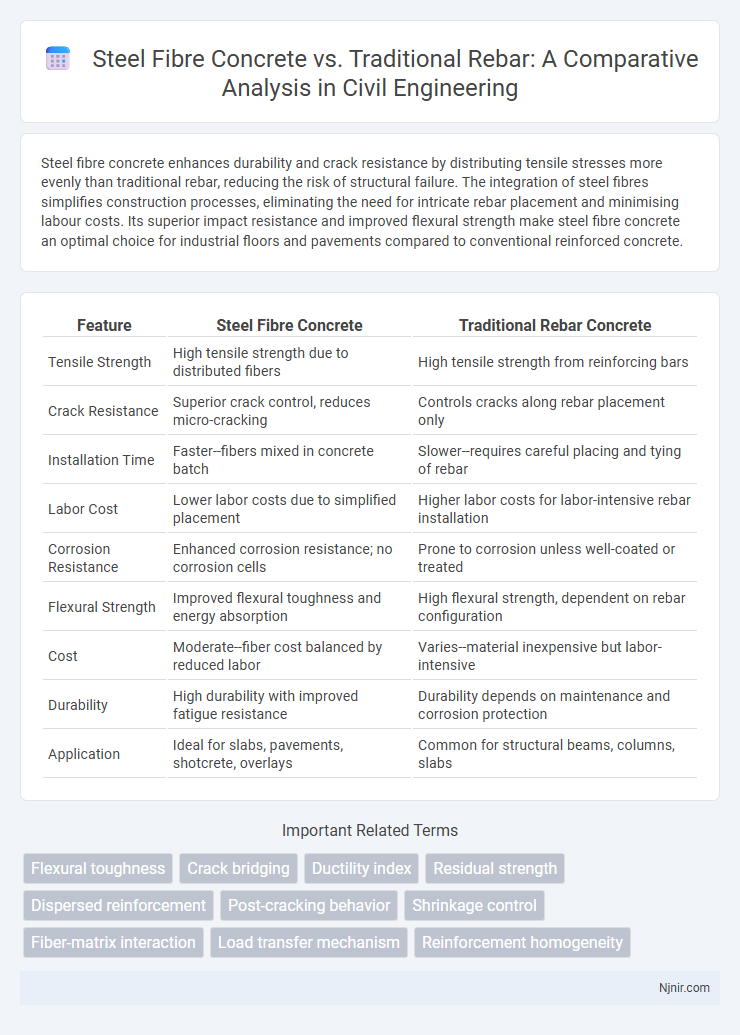

Table of Comparison

| Feature | Steel Fibre Concrete | Traditional Rebar Concrete |

|---|---|---|

| Tensile Strength | High tensile strength due to distributed fibers | High tensile strength from reinforcing bars |

| Crack Resistance | Superior crack control, reduces micro-cracking | Controls cracks along rebar placement only |

| Installation Time | Faster--fibers mixed in concrete batch | Slower--requires careful placing and tying of rebar |

| Labor Cost | Lower labor costs due to simplified placement | Higher labor costs for labor-intensive rebar installation |

| Corrosion Resistance | Enhanced corrosion resistance; no corrosion cells | Prone to corrosion unless well-coated or treated |

| Flexural Strength | Improved flexural toughness and energy absorption | High flexural strength, dependent on rebar configuration |

| Cost | Moderate--fiber cost balanced by reduced labor | Varies--material inexpensive but labor-intensive |

| Durability | High durability with improved fatigue resistance | Durability depends on maintenance and corrosion protection |

| Application | Ideal for slabs, pavements, shotcrete, overlays | Common for structural beams, columns, slabs |

Introduction to Steel Fibre Concrete and Traditional Rebar

Steel fibre concrete incorporates small, discrete steel fibers uniformly distributed throughout the concrete matrix, enhancing tensile strength, crack resistance, and durability compared to traditional concrete. Traditional rebar consists of steel rods embedded in concrete to provide structural reinforcement, primarily resisting tensile stresses in large-scale construction. Steel fibre concrete offers improved crack control and impact resistance, reducing the need for conventional rebar placement and simplifying construction processes.

Composition and Material Properties

Steel fibre concrete integrates short, discrete steel fibres uniformly dispersed within the concrete matrix, enhancing tensile strength and crack resistance, while traditional rebar relies on continuous steel bars embedded for reinforcement. The steel fibres, typically ranging from 30 to 50 mm in length with high tensile strength of approximately 1100 MPa, improve ductility and impact resistance without compromising workability. In contrast, rebar is composed of high-strength carbon steel, often coated to resist corrosion, providing localized reinforcement but requiring precise placement and anchorage within the concrete structure.

Installation and Construction Techniques

Steel fibre concrete simplifies installation by eliminating the need for precise placement and tying of traditional rebar, reducing labor time and costs on site. Unlike conventional reinforcement, steel fibres are dispersed uniformly in the concrete mix, providing multidirectional strength without requiring complex formwork or splicing techniques. This innovation enhances construction efficiency, allowing faster casting and accelerated project timelines in infrastructure and industrial applications.

Structural Performance and Load Bearing

Steel fibre concrete offers enhanced structural performance through improved crack resistance and toughness, distributing loads more evenly across the matrix compared to traditional rebar. Load bearing capacity is significantly increased as steel fibers bridge micro-cracks and delay failure, providing higher flexural strength and ductility. Traditional rebar relies on discrete steel bars for reinforcement, which can lead to localized stress concentrations, whereas steel fibre concrete ensures a more uniform stress distribution throughout the structure.

Crack Control and Durability

Steel fibre concrete significantly improves crack control by distributing stresses more evenly throughout the concrete matrix, reducing crack widths and preventing crack propagation compared to traditional rebar which localizes reinforcement. The enhanced crack control in steel fibre concrete results in superior durability, as smaller and fewer cracks limit the ingress of moisture, chlorides, and other corrosive agents that typically degrade concrete and steel reinforcements. Studies show steel fibre reinforced concrete extends service life up to 30% longer than conventional rebar systems due to its improved resistance to cracking and subsequent corrosion-related damage.

Cost Analysis and Economic Considerations

Steel fibre concrete reduces labor and installation costs due to faster placement and elimination of tying rebar, resulting in up to 20% savings in overall project expenses. Traditional rebar involves higher material costs and extensive labor for cutting, bending, and tying, increasing total construction time and associated expenses. Lifecycle cost analysis shows steel fibre concrete offers better economic efficiency by minimizing maintenance and repair needs, despite comparable initial material costs.

Flexibility in Design Applications

Steel fibre concrete offers enhanced flexibility in design applications compared to traditional rebar by allowing more uniform distribution of tensile stresses and eliminating the need for precise placement of reinforcement bars. This technology enables complex shapes and thinner sections without compromising structural integrity, making it ideal for architectural elements and curved surfaces. Traditional rebar, while strong, requires meticulous arrangement and limits design adaptability due to its rigid form and spacing requirements.

Maintenance and Longevity

Steel fibre concrete reduces maintenance needs due to its enhanced crack resistance and improved load distribution, minimizing corrosion risks common with traditional rebar. Traditional rebar requires regular inspection and potential repair as exposed steel can rust, compromising structural integrity over time. Studies show steel fibre concrete structures often exhibit longer service life and lower lifecycle costs, making them a durable alternative in construction.

Sustainability and Environmental Impact

Steel fibre concrete reduces environmental impact by minimizing the need for traditional rebar, lowering steel consumption and waste generation. It enhances durability and crack resistance, extending the lifespan of structures and decreasing the frequency of repairs and material replacements. This sustainable alternative also simplifies construction processes, reducing energy use and carbon emissions associated with rebar fabrication and installation.

Industry Standards and Future Trends

Steel fibre concrete offers enhanced crack resistance and improved durability compared to traditional rebar, aligning with industry standards such as ASTM A820 and EN 14889 for fiber reinforcement. The construction sector increasingly adopts hybrid reinforcement systems that meet stringent structural performance criteria while reducing labor costs and installation time. Future trends emphasize advancements in fiber materials and smart monitoring technologies to optimize concrete performance and sustainability in infrastructure projects.

Flexural toughness

Steel fibre concrete exhibits significantly higher flexural toughness than traditional rebar-reinforced concrete due to its distributed crack-bridging ability and enhanced energy absorption capacity.

Crack bridging

Steel fibre concrete enhances crack bridging by distributing tensile stresses more evenly across microcracks compared to traditional rebar, reducing crack width and improving overall durability.

Ductility index

Steel fibre concrete exhibits a higher ductility index than traditional rebar-reinforced concrete, enhancing its ability to deform under stress without sudden failure.

Residual strength

Steel fibre concrete exhibits superior residual strength compared to traditional rebar by providing enhanced crack control and increased post-crack load-bearing capacity.

Dispersed reinforcement

Steel fibre concrete provides enhanced dispersed reinforcement by uniformly distributing microfibers throughout the matrix, improving crack resistance and durability compared to traditional rebar's localized reinforcement.

Post-cracking behavior

Steel fibre concrete exhibits superior post-cracking behavior with enhanced crack bridging, increased toughness, and improved load-carrying capacity compared to traditional rebar-reinforced concrete.

Shrinkage control

Steel fibre concrete reduces shrinkage cracks more effectively than traditional rebar by providing distributed reinforcement throughout the matrix.

Fiber-matrix interaction

Steel fibre concrete enhances fiber-matrix interaction by providing improved crack resistance, better load transfer, and increased durability compared to traditional rebar reinforcement.

Load transfer mechanism

Steel fibre concrete enhances load transfer through multidirectional crack bridging and stress distribution, whereas traditional rebar relies on discrete tensile reinforcement bars embedded within the concrete matrix.

Reinforcement homogeneity

Steel fibre concrete provides superior reinforcement homogeneity compared to traditional rebar by evenly distributing tensile strength throughout the concrete matrix, reducing weak points and crack propagation.

Steel fibre concrete vs traditional rebar Infographic

njnir.com

njnir.com