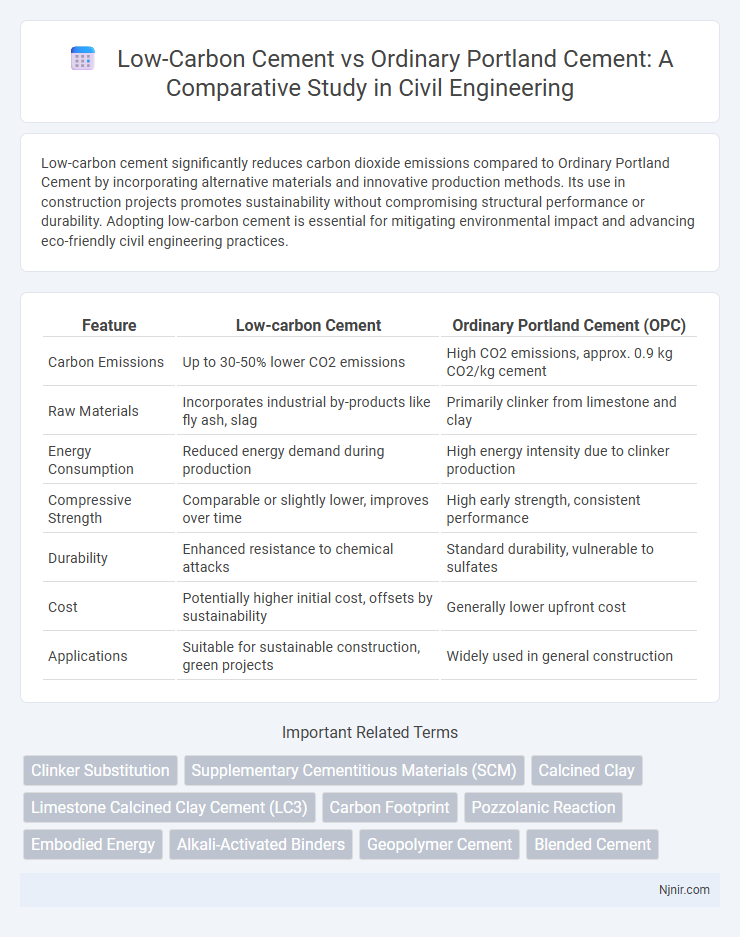

Low-carbon cement significantly reduces carbon dioxide emissions compared to Ordinary Portland Cement by incorporating alternative materials and innovative production methods. Its use in construction projects promotes sustainability without compromising structural performance or durability. Adopting low-carbon cement is essential for mitigating environmental impact and advancing eco-friendly civil engineering practices.

Table of Comparison

| Feature | Low-carbon Cement | Ordinary Portland Cement (OPC) |

|---|---|---|

| Carbon Emissions | Up to 30-50% lower CO2 emissions | High CO2 emissions, approx. 0.9 kg CO2/kg cement |

| Raw Materials | Incorporates industrial by-products like fly ash, slag | Primarily clinker from limestone and clay |

| Energy Consumption | Reduced energy demand during production | High energy intensity due to clinker production |

| Compressive Strength | Comparable or slightly lower, improves over time | High early strength, consistent performance |

| Durability | Enhanced resistance to chemical attacks | Standard durability, vulnerable to sulfates |

| Cost | Potentially higher initial cost, offsets by sustainability | Generally lower upfront cost |

| Applications | Suitable for sustainable construction, green projects | Widely used in general construction |

Introduction to Cement Types in Civil Engineering

Low-carbon cement significantly reduces CO2 emissions compared to Ordinary Portland Cement (OPC), making it a sustainable alternative in civil engineering projects. OPC, known for its high strength and durability, remains the most commonly used binder in construction but contributes substantially to global carbon emissions. Innovations in low-carbon cement include blended materials and alternative clinker technologies that lower the carbon footprint while maintaining performance standards essential for infrastructure development.

Defining Low-Carbon Cement and Ordinary Portland Cement

Low-carbon cement is formulated to reduce carbon dioxide emissions during production by incorporating alternative materials such as fly ash, slag, or calcined clays, resulting in a smaller carbon footprint compared to traditional cements. Ordinary Portland Cement (OPC) is the most common type of cement, produced primarily from limestone and clay through the calcination process, which generates significant CO2 emissions. The key distinction lies in low-carbon cement's emphasis on sustainability and environmental impact reduction while maintaining comparable strength and durability to OPC.

Raw Materials and Production Processes

Low-carbon cement primarily utilizes alternative raw materials such as industrial by-products like fly ash, slag, and calcined clays, reducing reliance on traditional limestone and clay used in Ordinary Portland Cement (OPC). The production process for low-carbon cement involves lower kiln temperatures and reduced clinker content, significantly decreasing carbon dioxide emissions compared to OPC. Innovations in raw material selection and energy-efficient manufacturing contribute to a smaller carbon footprint, promoting sustainable construction practices.

Carbon Footprint Comparison

Low-carbon cement significantly reduces carbon emissions compared to Ordinary Portland Cement (OPC), which is responsible for approximately 8% of global CO2 emissions. Innovations in low-carbon cement involve substituting clinker with industrial byproducts like fly ash and slag, lowering the carbon footprint by up to 30-50%. Lifecycle assessments reveal that adopting low-carbon cement can cut embodied carbon in concrete from around 800 kg CO2 per cubic meter for OPC to as low as 400-500 kg CO2 per cubic meter.

Mechanical Properties and Performance

Low-carbon cement exhibits comparable compressive strength to Ordinary Portland Cement (OPC) while significantly reducing carbon dioxide emissions during production. Mechanical properties such as tensile strength and durability are optimized in low-carbon formulations through the inclusion of supplementary cementitious materials like fly ash and slag. Performance in structural applications demonstrates enhanced resistance to chemical attack and improved long-term stability compared to OPC, making it a sustainable alternative without compromising engineering standards.

Durability and Lifespan in Construction

Low-carbon cement demonstrates enhanced durability compared to Ordinary Portland Cement (OPC) by exhibiting superior resistance to chemical attacks and reduced permeability, which significantly extends the lifespan of construction structures. Studies indicate that low-carbon cement mixtures can endure over 50 years with minimal degradation, whereas OPC-based structures typically require more frequent maintenance due to higher susceptibility to carbonation and chloride ingress. The improved microstructure of low-carbon cement contributes to long-term performance, making it a sustainable choice for resilient infrastructure development.

Cost Analysis and Economic Feasibility

Low-carbon cement typically incurs 10-20% higher initial production costs compared to Ordinary Portland Cement (OPC) due to advanced materials and energy-efficient processes. However, its long-term economic feasibility improves through savings on carbon taxes, regulatory incentives, and growing market demand for sustainable construction materials. Life-cycle cost assessments reveal that despite higher upfront expenses, low-carbon cement can yield lower total costs over a 50-year infrastructure lifespan.

Environmental Impact and Sustainability

Low-carbon cement significantly reduces CO2 emissions compared to Ordinary Portland Cement (OPC), which is responsible for approximately 8% of global carbon dioxide emissions. By utilizing alternative raw materials and incorporating industrial by-products like fly ash or slag, low-carbon cement lowers the environmental footprint and enhances sustainability in construction. This shift supports global climate goals by reducing greenhouse gas emissions and conserving natural resources.

Regulatory Standards and Certifications

Low-carbon cement must comply with increasingly stringent regulatory standards aimed at reducing carbon emissions in the construction industry, such as ISO 14067 and EN 15804 certifications, which measure product carbon footprints and sustainability performance. Ordinary Portland Cement (OPC) predominantly meets traditional standards like ASTM C150 and EN 197-1, focusing on mechanical strength and durability rather than environmental impact. Certifications like LEED and BREEAM increasingly favor low-carbon cement due to their emphasis on reducing embodied carbon, influencing procurement policies and building codes globally.

Future Trends in Cement Technology

Low-carbon cement is emerging as a key innovation to reduce CO2 emissions in the construction industry, with advances in alternative raw materials and novel clinker composition dramatically lowering carbon footprints compared to Ordinary Portland Cement (OPC). Future trends emphasize incorporation of supplementary cementitious materials (SCMs) like fly ash, slag, and calcined clays that enhance durability and performance while minimizing environmental impact. Research in carbon capture integration and geopolymer cement formulations aims to revolutionize sustainable building practices by providing scalable, low-emission alternatives to traditional OPC.

Clinker Substitution

Low-carbon cement reduces environmental impact by replacing a significant portion of clinker with supplementary materials such as slag, fly ash, or calcined clay, lowering CO2 emissions compared to Ordinary Portland Cement.

Supplementary Cementitious Materials (SCM)

Low-carbon cement integrates Supplementary Cementitious Materials (SCMs) like fly ash, slag, and silica fume to reduce CO2 emissions by partially replacing Ordinary Portland Cement without compromising strength and durability.

Calcined Clay

Low-carbon cement utilizing calcined clay significantly reduces CO2 emissions by replacing a portion of clinker in Ordinary Portland Cement while maintaining comparable strength and durability.

Limestone Calcined Clay Cement (LC3)

Limestone Calcined Clay Cement (LC3) reduces carbon emissions by up to 40% compared to Ordinary Portland Cement while maintaining comparable strength and durability.

Carbon Footprint

Low-carbon cement reduces carbon footprint by emitting up to 40% less CO2 compared to ordinary Portland cement during production.

Pozzolanic Reaction

Low-carbon cement enhances durability and reduces CO2 emissions by utilizing pozzolanic reactions that chemically bind calcium hydroxide with silica and alumina, improving strength and reducing environmental impact compared to Ordinary Portland Cement.

Embodied Energy

Low-carbon cement reduces embodied energy by up to 30% compared to Ordinary Portland Cement, significantly lowering its environmental impact.

Alkali-Activated Binders

Alkali-activated binders in low-carbon cement reduce CO2 emissions by utilizing industrial byproducts like fly ash or slag, offering a sustainable alternative to Ordinary Portland Cement with comparable durability and strength.

Geopolymer Cement

Geopolymer cement, a low-carbon alternative to ordinary Portland cement, reduces CO2 emissions by up to 80% through the use of industrial byproducts like fly ash and slag, offering enhanced durability and resistance to chemical attacks.

Blended Cement

Blended cement, incorporating supplementary materials like fly ash or slag, reduces carbon emissions by up to 40% compared to ordinary Portland cement while maintaining comparable strength and durability.

Low-carbon Cement vs Ordinary Portland Cement Infographic

njnir.com

njnir.com